-

What happened?

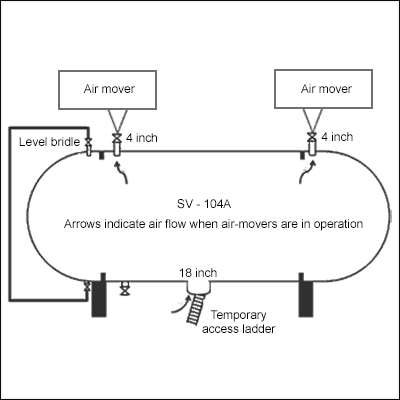

A gasoline storage vessel was hot nitrogen swept and flushed with water and a chemical to control lower explosive limit vapors.

Residual charcoal needed to be removed with a fire hose.

Two workers entered the vessel wearing full face cartridge respirators and flame retardant polyvinyl coated suits.

Although air-movers were in place to maintain flow of outside air, after 30 minutes the water/charcoal slurry began to smell of gasoline.

The benzene and lower explosive limit vapour levels reached 30% at one of the air outlets located at the top of the vessel.

An air horn signal was triggered and both workers safely exited.

-

Why did it happen?

- The mechanical ventilation was interrupted. This was caused by the air supply being cut off from the air-movers.

- Upon investigation, a kink was found in the air supply hose.

- Personnel lacked experience in performing internal vessel cleaning.

-

What did they learn?

Having the right PPE is mandatory.

Confined spaces with potential for hazardous atmosphere must be continuously monitored for lower explosive limit vapour and oxygen levels when workers are inside.

Follow air hose management procedures and continue to verify air-mover operations.Personnel must have adequate experience and training for the specific job tasks to be performed.

During the operation, a confined space entry attendant must be positioned on stand by.

-

Ask yourself or your crew

What other actions could have been taken?

How could something like this happen here?

What could have happened if the workers did not leave the tank?

What aspects of tank cleaning operation do we not fully understand?

How can we improve confined space tasks to prevent this, and other, issues?

Add to homescreen

Content name

Select existing category:

Content name

New collection

Edit collection

What happened?

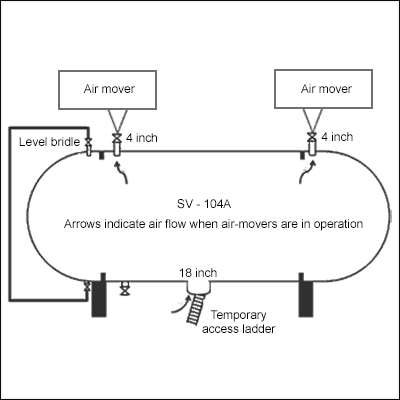

A gasoline storage vessel was hot nitrogen swept and flushed with water and a chemical to control lower explosive limit vapors.

Residual charcoal needed to be removed with a fire hose.

Two workers entered the vessel wearing full face cartridge respirators and flame retardant polyvinyl coated suits.

Although air-movers were in place to maintain flow of outside air, after 30 minutes the water/charcoal slurry began to smell of gasoline.

The benzene and lower explosive limit vapour levels reached 30% at one of the air outlets located at the top of the vessel.

An air horn signal was triggered and both workers safely exited.

Why did it happen?

- The mechanical ventilation was interrupted. This was caused by the air supply being cut off from the air-movers.

- Upon investigation, a kink was found in the air supply hose.

- Personnel lacked experience in performing internal vessel cleaning.

What did they learn?

Having the right PPE is mandatory.

Confined spaces with potential for hazardous atmosphere must be continuously monitored for lower explosive limit vapour and oxygen levels when workers are inside.

Follow air hose management procedures and continue to verify air-mover operations.

Personnel must have adequate experience and training for the specific job tasks to be performed.

During the operation, a confined space entry attendant must be positioned on stand by.

Ask yourself or your crew

What other actions could have been taken?

How could something like this happen here?

What could have happened if the workers did not leave the tank?

What aspects of tank cleaning operation do we not fully understand?

How can we improve confined space tasks to prevent this, and other, issues?

Two workers entered the vessel wearing full face cartridge respirators and flame retardant polyvinyl coated suits... An air horn signal was triggered and both workers safely exited the space with no adverse effects.