-

What happened?

Workers were removing sections of roof made of coal tar pitch using push-from-behind circular saws and a motorized mechanical shearing machine.

Debris was lifted onto wagons and transported to chutes that emptied into roll-off bins.

The job risk assessment required use of water suppression and dust filtering masks to protect workers. However, water suppression was not used.

Workers were exposed to dangerous levels of poly aromatic hydrocarbon dust. Industrial hygiene sampling results exceeded the company 8-hour time weighted average exposure limit of 0.005 mg/m3.

-

Why did it happen?

Water suppression was not used because an adequate water supply was not available.

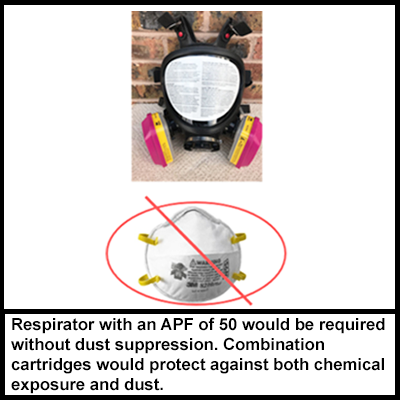

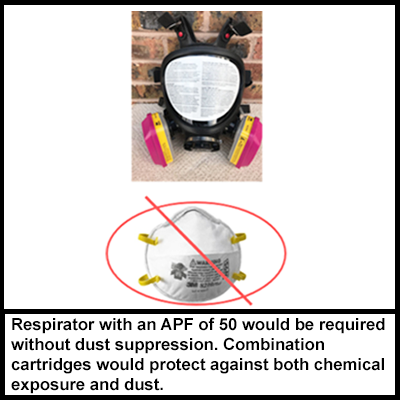

Workers only used dust filtering masks – but without water suppression this was not enough to protect them.

They did not stop and reassess the job once it was known that water suppression was not possible.

-

What did they learn?

Implement a written procedure regarding work involving coal tar pitch roofs including engineering controls, hazard recognition and personal protective equipment.

Stop the job if the procedure cannot be followed. Do not underestimate the risk.

Using water as a means of dust suppression is normal when performing this work. Include alternative ways for providing water where it is not readily available.

All sites should account for polyaromatic hydrocarbon for roofing contractors in exposure assessment plans and perform annual sampling.

-

Ask yourself or your crew

What other actions could have been taken?

How do we make sure we have the right barriers in place – including water suppression, and the right PPE?

Why do you think these workers didn’t stop the job when the plan changed?

What factors (e.g. time pressure) might make us do something similar? What can we do to solve these?

Add to homescreen

Content name

Select existing category:

Content name

New collection

Edit collection

What happened?

Workers were removing sections of roof made of coal tar pitch using push-from-behind circular saws and a motorized mechanical shearing machine.

Debris was lifted onto wagons and transported to chutes that emptied into roll-off bins.

The job risk assessment required use of water suppression and dust filtering masks to protect workers. However, water suppression was not used.

Workers were exposed to dangerous levels of poly aromatic hydrocarbon dust. Industrial hygiene sampling results exceeded the company 8-hour time weighted average exposure limit of 0.005 mg/m3.

Why did it happen?

Water suppression was not used because an adequate water supply was not available.

Workers only used dust filtering masks – but without water suppression this was not enough to protect them.

They did not stop and reassess the job once it was known that water suppression was not possible.

What did they learn?

Implement a written procedure regarding work involving coal tar pitch roofs including engineering controls, hazard recognition and personal protective equipment.

Stop the job if the procedure cannot be followed. Do not underestimate the risk.

Using water as a means of dust suppression is normal when performing this work. Include alternative ways for providing water where it is not readily available.

All sites should account for polyaromatic hydrocarbon for roofing contractors in exposure assessment plans and perform annual sampling.

Ask yourself or your crew

What other actions could have been taken?

How do we make sure we have the right barriers in place – including water suppression, and the right PPE?

Why do you think these workers didn’t stop the job when the plan changed?

What factors (e.g. time pressure) might make us do something similar? What can we do to solve these?

Workers were exposed to dangerous levels of poly aromatic hydrocarbon dust while removing sections of roof made of coal tar pitch. Although the risk assessment required water use for suppression, an adequate water supply was not available.