-

What happened?

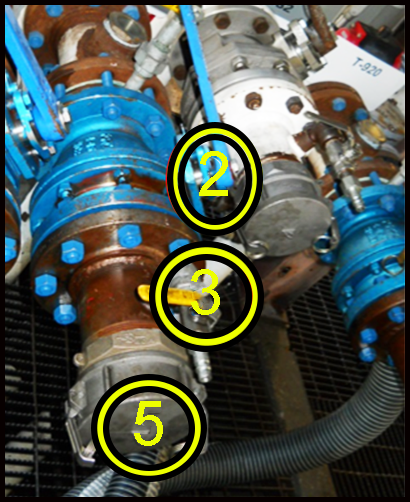

1. A worker was clearing the loading lines by sending the pig back to the blend floor.

2. The worker heard air pressure potentially bleeding by the manual valve on the pump island header.

3. The worker opened the 6 inch bleeder valve and heard air escaping.

4. He then released the ears on the header cam-lock cap, without fully releasing the pressure via the bleeder.

5. This sent the cap flying off into the finished product tank farm. If he had been in the way, he could have been seriously injured by the cap.

-

Why did it happen?

The bleeder valve was used to check for pressure as there were no external gauges to monitor the pressure trapped behind the cap.

The worker did not fully open the 6 inch bleeder valve to relieve pressure when checking the cause of escaping air.

The cam-lock ears on the header cap were opened by the worker while it was under pressure.

-

What did they learn?

Air pressure can build up behind the cap if the manual control valve does not properly seal or if it is not fully closed.

Trapped pressure can be identified by installing gauges.

The cam-lock ears on the header cap should not be opened while under pressure.

Pressure can be relieved by fully opening the valve.

Position yourself and others out of the line of fire.

-

Ask yourself or your crew

What other actions could have been taken?

How do you ensure that every step of a critical procedure is followed as intended?

How would you intervene when someone is working in an unsafe manner?

How should personnel comply with work management programs, especially at remote locations?

What should be the disciplinary action for non-compliance with the work management system?

Add to homescreen

Content name

Select existing category:

Content name

New collection

Edit collection

What happened?

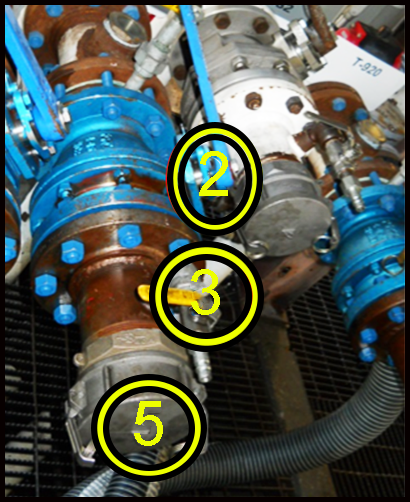

1. A worker was clearing the loading lines by sending the pig back to the blend floor.

2. The worker heard air pressure potentially bleeding by the manual valve on the pump island header.

3. The worker opened the 6 inch bleeder valve and heard air escaping.

4. He then released the ears on the header cam-lock cap, without fully releasing the pressure via the bleeder.

5. This sent the cap flying off into the finished product tank farm. If he had been in the way, he could have been seriously injured by the cap.

Why did it happen?

The bleeder valve was used to check for pressure as there were no external gauges to monitor the pressure trapped behind the cap.

The worker did not fully open the 6 inch bleeder valve to relieve pressure when checking the cause of escaping air.

The cam-lock ears on the header cap were opened by the worker while it was under pressure.

What did they learn?

Air pressure can build up behind the cap if the manual control valve does not properly seal or if it is not fully closed.

Trapped pressure can be identified by installing gauges.

The cam-lock ears on the header cap should not be opened while under pressure.

Pressure can be relieved by fully opening the valve.

Position yourself and others out of the line of fire.

Ask yourself or your crew

What other actions could have been taken?

How do you ensure that every step of a critical procedure is followed as intended?

How would you intervene when someone is working in an unsafe manner?

How should personnel comply with work management programs, especially at remote locations?

What should be the disciplinary action for non-compliance with the work management system?

A worker was clearing the loading lines by sending the pig back to the blend floor... This sent the cap flying off into the finished product tank farm.