-

What happened?

Multiple teams were working on returning a sour gas oil charge line to service.

The 1100 feet/335 metre line had been recently repaired and leak checked.

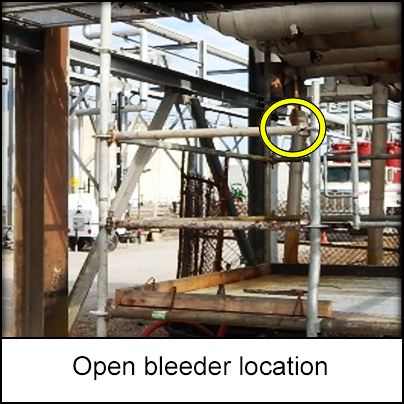

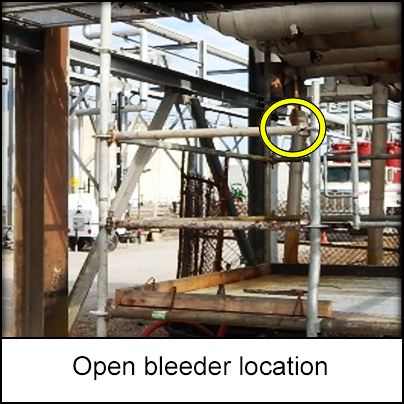

Upon opening of discharge block valves at the charge pumps, head pressure from the product storage tank allowed product to be pushed to an open bleeder where loss of containment occurred.

While making routine rounds, operations discovered the open bleeder.

-

Why did it happen?

During the process of aligning the system, a bleeder was inadvertently left open.

It was not clear which team was responsible for ensuring bleeders were closed.

-

What did they learn?

Define ownership for activities that involve more than one team.

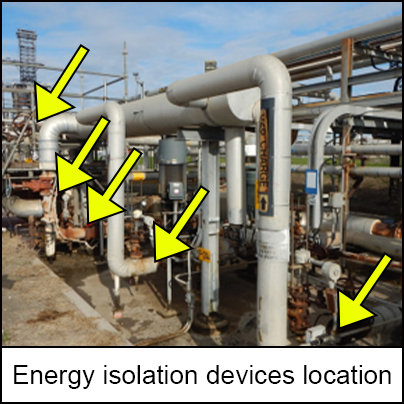

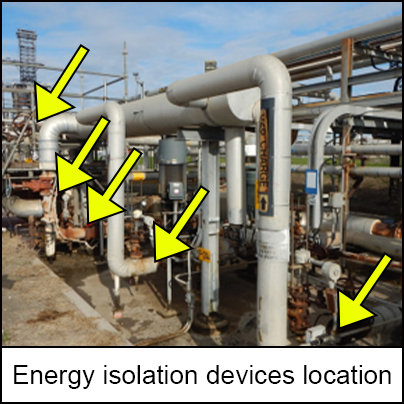

Include verification steps for the following:

- Energy/equipment isolation conditions that require sign off (open bleeders/vents/drains).

- Identification of management of change (MOC) in recommissioning.

- Hold points for operations to prevent MOC violation when re-commissioning equipment (e.g. MOC tag on lock box).

-

Ask yourself or your crew

How can something like this happen here?

What other actions could have been taken?

How can we ensure all safety critical tasks have an ‘owner’?

Who is responsible (what person or team) for today’s tasks?

What is your role in ensuring that all necessary verifications have been successfully completed before recommissioning?

Add to homescreen

Content name

Select existing category:

Content name

New collection

Edit collection

What happened?

Multiple teams were working on returning a sour gas oil charge line to service.

The 1100 feet/335 metre line had been recently repaired and leak checked.

Upon opening of discharge block valves at the charge pumps, head pressure from the product storage tank allowed product to be pushed to an open bleeder where loss of containment occurred.

While making routine rounds, operations discovered the open bleeder.

Why did it happen?

During the process of aligning the system, a bleeder was inadvertently left open.

It was not clear which team was responsible for ensuring bleeders were closed.

What did they learn?

Define ownership for activities that involve more than one team.

Include verification steps for the following:

- Energy/equipment isolation conditions that require sign off (open bleeders/vents/drains).

- Identification of management of change (MOC) in recommissioning.

- Hold points for operations to prevent MOC violation when re-commissioning equipment (e.g. MOC tag on lock box).

Ask yourself or your crew

How can something like this happen here?

What other actions could have been taken?

How can we ensure all safety critical tasks have an ‘owner’?

Who is responsible (what person or team) for today’s tasks?

What is your role in ensuring that all necessary verifications have been successfully completed before recommissioning?

Multiple teams were working on recommissioning a sour gas oil line. A bleeder was inadvertently left open, leading to loss of containment.