-

What happened?

There have been a number of incidents involving scaffolding stair units or treads failing.

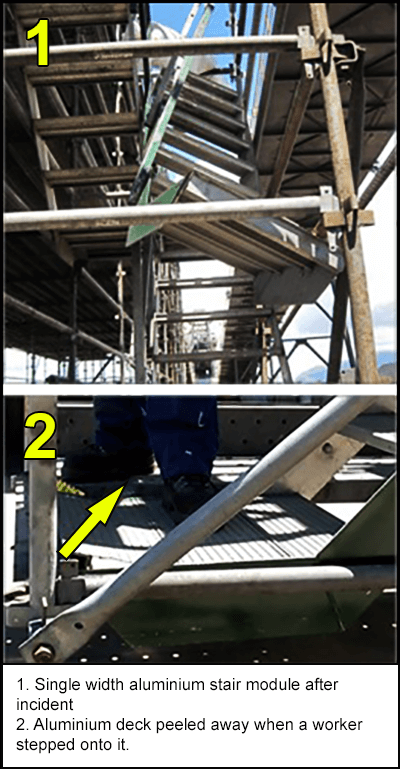

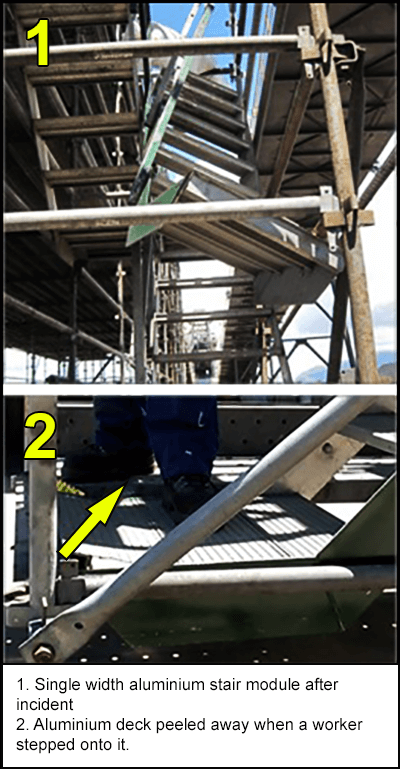

Incident 1:

The welds at one end of a single stair module failed when a worker stepped onto the landing. The top of the landing peeled away and the stairs dropped off the transom which was supporting it. The worker fell, catching his hand on the V-pressing of a standard, tearing off his finger.

Incident 2:

One section of a double stair module dropped off the supporting transoms when a worker stepped on it. The supporting scaffolding was ‘out of square’ and not supported enough by the transoms. The worker fell to the level below, receiving injuries.

-

Why did it happen?

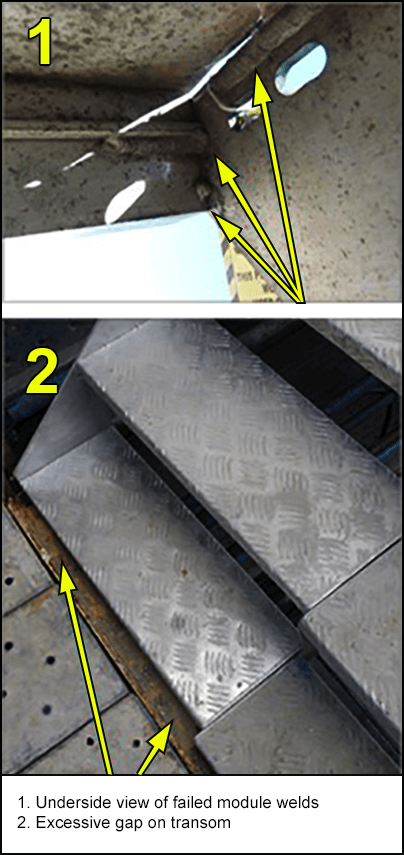

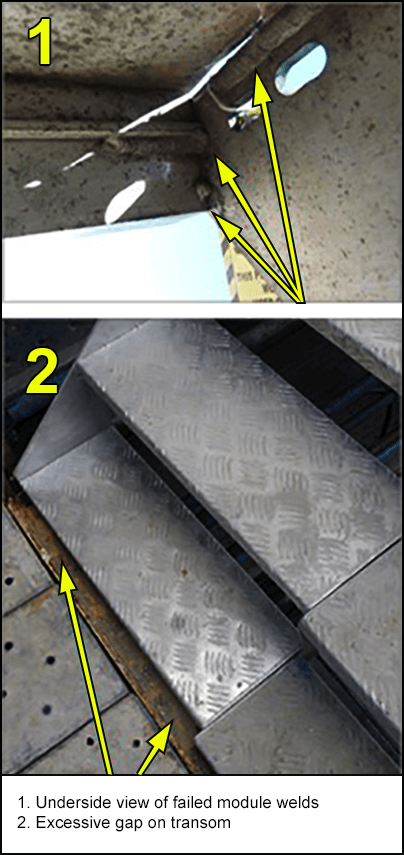

If the gap between the end of the stair module and the vertical face of the transom is too big, the transoms can’t give enough support to both ends of the stairs.

Inadequate welds at critical points on the stair modules – often tack welds are used instead of continuous or stitch welds.

Existing damage or cracks to stair modules not being noticed – occurring during assembly, dismantling or transport.

Supporting transoms not being installed correctly – they are able to twist if the connections are loose.

-

What did they learn?

Ensure there is correct transom support underneath the stair modules. Comply with recognised codes of practice, follow manufacturer’s guidelines and make sure that the maximum gap between the stair module and transom is 15mm (0.5in).

Ensure the stair module is structurally sound and only contains continuous or stitch welds.

Each scaffolding bay needs to be square.

Check the module for any defects or damage before it is sent to site and before it is signed off for use. Inspect stair modules at least every 30 days.

Double width stair halves should be secured together with proprietary system bolts as recommended by the manufacturer.

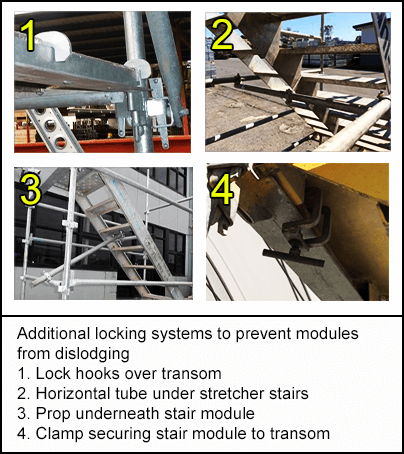

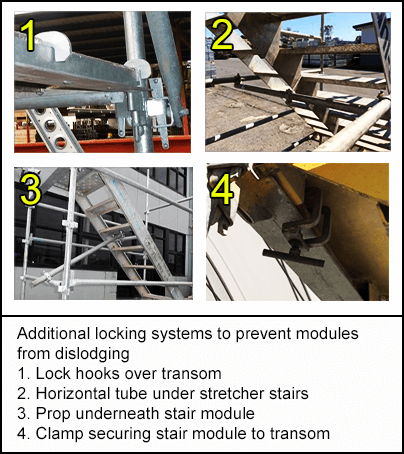

Use additional locking systems to prevent the stairs from dislodging, e.g. hooks, props or clamping systems.

All scaffolding to be erected by competent people.

-

Ask yourself or your crew

How can something like this happen here?

What type of weld has been used on our stairs?

When were the stairs last inspected? How can you check?

What are the signs of an unsafe stair module?

What additional measures can we take? (e.g. props or clamps)

Add to homescreen

Content name

Select existing category:

Content name

New collection

Edit collection

What happened?

There have been a number of incidents involving scaffolding stair units or treads failing.

Incident 1:

The welds at one end of a single stair module failed when a worker stepped onto the landing. The top of the landing peeled away and the stairs dropped off the transom which was supporting it. The worker fell, catching his hand on the V-pressing of a standard, tearing off his finger.

Incident 2:

One section of a double stair module dropped off the supporting transoms when a worker stepped on it. The supporting scaffolding was ‘out of square’ and not supported enough by the transoms. The worker fell to the level below, receiving injuries.

Why did it happen?

If the gap between the end of the stair module and the vertical face of the transom is too big, the transoms can’t give enough support to both ends of the stairs.

Inadequate welds at critical points on the stair modules – often tack welds are used instead of continuous or stitch welds.

Existing damage or cracks to stair modules not being noticed – occurring during assembly, dismantling or transport.

Supporting transoms not being installed correctly – they are able to twist if the connections are loose.

What did they learn?

Ensure there is correct transom support underneath the stair modules. Comply with recognised codes of practice, follow manufacturer’s guidelines and make sure that the maximum gap between the stair module and transom is 15mm (0.5in).

Ensure the stair module is structurally sound and only contains continuous or stitch welds.

Each scaffolding bay needs to be square.

Check the module for any defects or damage before it is sent to site and before it is signed off for use. Inspect stair modules at least every 30 days.

Double width stair halves should be secured together with proprietary system bolts as recommended by the manufacturer.

Use additional locking systems to prevent the stairs from dislodging, e.g. hooks, props or clamping systems.

All scaffolding to be erected by competent people.

Ask yourself or your crew

How can something like this happen here?

What type of weld has been used on our stairs?

When were the stairs last inspected? How can you check?

What are the signs of an unsafe stair module?

What additional measures can we take? (e.g. props or clamps)

There have been a number of accidents due to stair module failure in scaffolding, partly due to incorrect installation, or defects not being noticed or inspected regularly.