-

What happened?

A worker was conducting a pre-operation in-line inspection (ILI) on a 20inch (50cm) gas gathering pipeline that had many bends and various height levels.

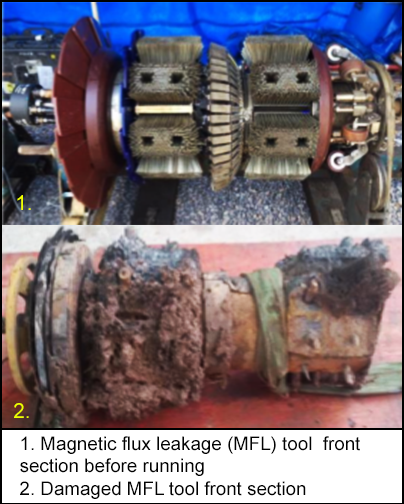

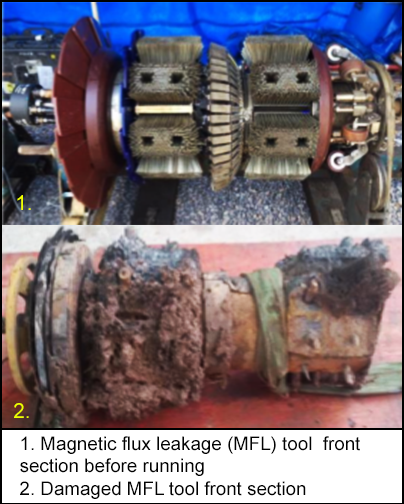

The worker was using a magnetic flux leakage (MFL) tool (smart pig).

The MFL tool was being pushed in a nitrogen pill using compressed air.

Too much air bypassed the tool and created a combustible environment.

The tool overheated and caught fire, causing enough heat to melt a hole in the pipeline.

Pressurised air and nitrogen escaped from the pipeline - causing a crater to form in the ground. Rocks and dust ejected over the immediate area.

-

Why did it happen?

Inadequate procedures - the MFL tool should have been propelled with nitrogen for minimum 14.5km (9m), then switched to compressed air. It only used nitrogen for 6km (3.7m), meaning the tool was not propelled at the right pressure and flow.

The dangers of introducing a combustible environment in the pipeline were not recognised by neither by the site team, vendors or supporting specialists.

The site team did not fully understand and mitigate the risk of a tool fire caused by the smart pig travelling through a pipeline with many bends and height variation.

-

What did they learn?

An oxygen-free environment is required to eliminate the risk of fires.

Higher pipeline back pressure is required to ensure speed control of in-line inspection (ILI) assessment tools.

The speed of the magnetic flux leakage (MFL) tool should be controlled so it maintains a constant speed, which reduces frictional heat and damage to the tool.

Ensure personnel can identify, initiate and follow management of change procedures.

-

Ask yourself or your crew

Have you ever been asked to carry out a task that might contradicts your safe work procedures? What could have happened?

You should always carry out a site-specific inspection before starting work. What should you check for today?

What safe work procedures do you need to keep in mind for today’s pigging activity?

What additional precautions do you think you could take?

Add to homescreen

Content name

Select existing category:

Content name

New collection

Edit collection

What happened?

A worker was conducting a pre-operation in-line inspection (ILI) on a 20inch (50cm) gas gathering pipeline that had many bends and various height levels.

The worker was using a magnetic flux leakage (MFL) tool (smart pig).

The MFL tool was being pushed in a nitrogen pill using compressed air.

Too much air bypassed the tool and created a combustible environment.

The tool overheated and caught fire, causing enough heat to melt a hole in the pipeline.

Pressurised air and nitrogen escaped from the pipeline - causing a crater to form in the ground. Rocks and dust ejected over the immediate area.

Why did it happen?

Inadequate procedures - the MFL tool should have been propelled with nitrogen for minimum 14.5km (9m), then switched to compressed air. It only used nitrogen for 6km (3.7m), meaning the tool was not propelled at the right pressure and flow.

The dangers of introducing a combustible environment in the pipeline were not recognised by neither by the site team, vendors or supporting specialists.

The site team did not fully understand and mitigate the risk of a tool fire caused by the smart pig travelling through a pipeline with many bends and height variation.

What did they learn?

An oxygen-free environment is required to eliminate the risk of fires.

Higher pipeline back pressure is required to ensure speed control of in-line inspection (ILI) assessment tools.

The speed of the magnetic flux leakage (MFL) tool should be controlled so it maintains a constant speed, which reduces frictional heat and damage to the tool.

Ensure personnel can identify, initiate and follow management of change procedures.

Ask yourself or your crew

Have you ever been asked to carry out a task that might contradicts your safe work procedures? What could have happened?

You should always carry out a site-specific inspection before starting work. What should you check for today?

What safe work procedures do you need to keep in mind for today’s pigging activity?

What additional precautions do you think you could take?

During a pre-operation in-line inspection (ILI) assessment using a magnetic flux leakage (MFL) tool on a 20inch (50cm) gas gathering system pipeline, a rupture occurred in the pipeline.