-

What happened?

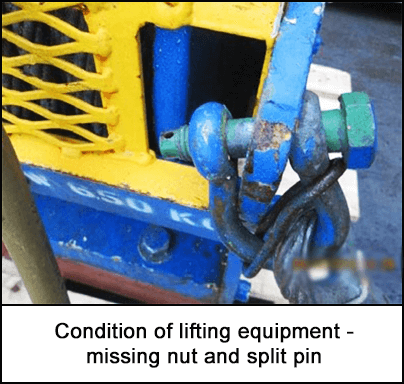

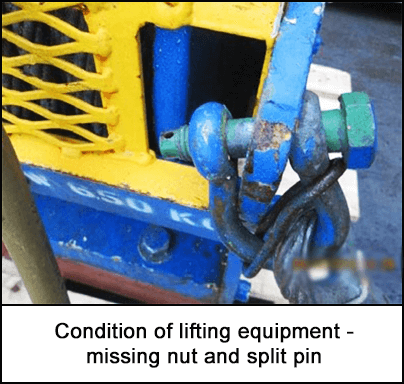

A hydraulic winch set was rented from a winch supplier.

Upon being returned, the winch supplier carried out a visual inspection.

They discovered the split pin and nut was missing from one of the 3.25Te shackles which were part of the winch lifting set.

It was unknown whether the lifting set was used in this condition or whether it worked its way loose during transport.

If used in this condition, it could have caused a dropped load incident.

-

Why did it happen?

The split pin and nut could have worked themselves loose as a result of vibration on the back of the truck during road transportation. If so, this would indicate that the split pin was incorrectly fitted or missing.

-

What did they learn?

Subject all rigging arrangements to a visual inspection before carrying out any lifting – ensure that split pins are securely in place to prevent nuts and bolts from working themselves loose.

Ensure that a lift supervisor inspects all loads for potential dropped objects and to ensure correct rigging and slinging arrangements are in place and correctly secured.

Reiterate the importance to all workers of thorough visual checking of lifting equipment before use, before mobilisation and demobilisation.

-

Ask yourself or your crew

Has anything like this ever happened on your site?

What inspections do you carry out on lifting equipment?

- Would these have caught this issue?

- Do these inspections apply to rented equipment?

What other hazards are there during lifting operations?

What barriers do we have in place to prevent or mitigate these hazards?

Add to homescreen

Content name

Select existing category:

Content name

New collection

Edit collection

What happened?

A hydraulic winch set was rented from a winch supplier.

Upon being returned, the winch supplier carried out a visual inspection.

They discovered the split pin and nut was missing from one of the 3.25Te shackles which were part of the winch lifting set.

It was unknown whether the lifting set was used in this condition or whether it worked its way loose during transport.

If used in this condition, it could have caused a dropped load incident.

Why did it happen?

The split pin and nut could have worked themselves loose as a result of vibration on the back of the truck during road transportation. If so, this would indicate that the split pin was incorrectly fitted or missing.

What did they learn?

Subject all rigging arrangements to a visual inspection before carrying out any lifting – ensure that split pins are securely in place to prevent nuts and bolts from working themselves loose.

Ensure that a lift supervisor inspects all loads for potential dropped objects and to ensure correct rigging and slinging arrangements are in place and correctly secured.

Reiterate the importance to all workers of thorough visual checking of lifting equipment before use, before mobilisation and demobilisation.

Ask yourself or your crew

Has anything like this ever happened on your site?

What inspections do you carry out on lifting equipment?

- Would these have caught this issue?

- Do these inspections apply to rented equipment?

What other hazards are there during lifting operations?

What barriers do we have in place to prevent or mitigate these hazards?

Rental equipment was returned to a winch supplier. They carried out a visual inspection of the equipment and discovered a split pin and nut missing from one of the shackles which were part of the winch lifting set.