-

What happened?

An engineer was replacing pistons on a vessel’s main engine as part of planned maintenance work.

After removing one of the pistons, the bottom end bearing cap was removed.

The crankshaft was being turned down and the engineer was holding the con rod off the crank pin – to avoid damage to the cylinder liner and crank pin/bottom end bearing shells.

The crank web counter balance came around and trapped the engineer’s finger between the con rod and crank web counter balance.

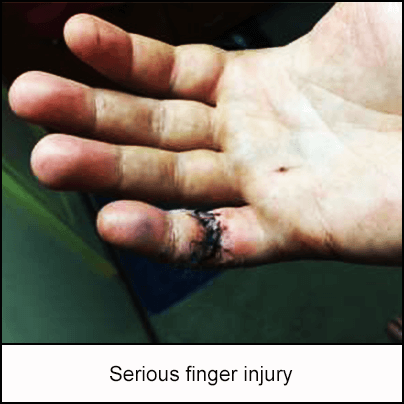

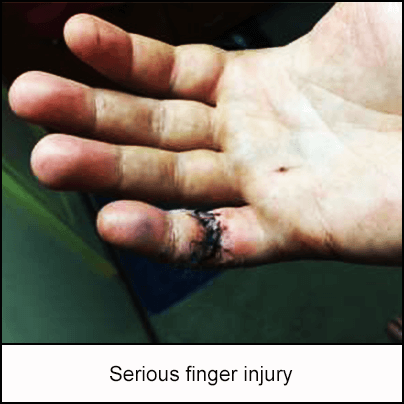

He turned the crank back and removed his hand. The engineer’s finger was seriously injured and required 7 stiches.

-

Why did it happen?

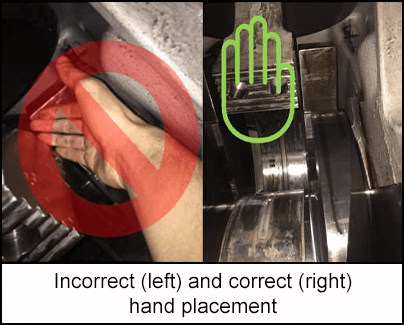

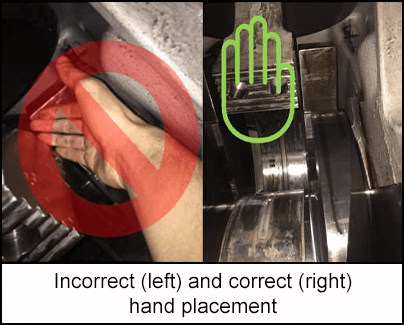

The engineer had their hand in an unsafe location within the machinery (between the con rod and counter balance)

They should have put their hand on the con rod itself, with thumb tucked in, to avoid pinch/trapping risks as the counter balance moved.

The engine manual provided insufficient specific guidance on handling components during maintenance.

What went well considering the situation?

The engineer was wearing the correct personal protective equipment (PPE), including mechanic gloves. This prevented a more severe injury.

The work was fully planned, and immediate first aid was available and external medical assistance was sought.

-

What did they learn?

Review and update risk assessments with emphasis on correct hand placement during tasks (for relevant equipment).

Consider different options for supporting the piston and connecting rod whilst turning the crankshaft out – use a substantial wooden lever or a soft strop to avoid the need to place hands inside.

Ensure work is fully planned – including risk assessments and toolbox talks.

Ensure that the engine manual/manufacturer’s guidance is clear and is being followed when undertaking maintenance work.

All workers should wear correct PPE.

All workers should be trained and competent to perform their duties.

-

Ask yourself or your crew

What should you do if the manufacturer’s guidance is not specific enough for your task?

Is there a safer way for conducting any of your activities?

What PPE do you need to wear for your role? Is it all available? What should you do if not?

Add to homescreen

Content name

Select existing category:

Content name

New collection

Edit collection

What happened?

An engineer was replacing pistons on a vessel’s main engine as part of planned maintenance work.

After removing one of the pistons, the bottom end bearing cap was removed.

The crankshaft was being turned down and the engineer was holding the con rod off the crank pin – to avoid damage to the cylinder liner and crank pin/bottom end bearing shells.

The crank web counter balance came around and trapped the engineer’s finger between the con rod and crank web counter balance.

He turned the crank back and removed his hand. The engineer’s finger was seriously injured and required 7 stiches.

Why did it happen?

The engineer had their hand in an unsafe location within the machinery (between the con rod and counter balance)

They should have put their hand on the con rod itself, with thumb tucked in, to avoid pinch/trapping risks as the counter balance moved.

The engine manual provided insufficient specific guidance on handling components during maintenance.

What went well considering the situation?

The engineer was wearing the correct personal protective equipment (PPE), including mechanic gloves. This prevented a more severe injury.

The work was fully planned, and immediate first aid was available and external medical assistance was sought.

What did they learn?

Review and update risk assessments with emphasis on correct hand placement during tasks (for relevant equipment).

Consider different options for supporting the piston and connecting rod whilst turning the crankshaft out – use a substantial wooden lever or a soft strop to avoid the need to place hands inside.

Ensure work is fully planned – including risk assessments and toolbox talks.

Ensure that the engine manual/manufacturer’s guidance is clear and is being followed when undertaking maintenance work.

All workers should wear correct PPE.

All workers should be trained and competent to perform their duties.

Ask yourself or your crew

What should you do if the manufacturer’s guidance is not specific enough for your task?

Is there a safer way for conducting any of your activities?

What PPE do you need to wear for your role? Is it all available? What should you do if not?

An engineer was replacing pistons on a vessel’s main engine as part of planned maintenance work. During the activity, one of his fingers became trapped. The engineer’s finger was seriously injured and required 7 stiches.