-

What happened?

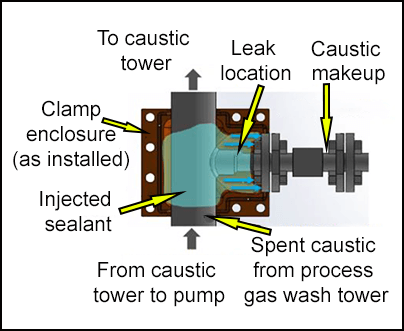

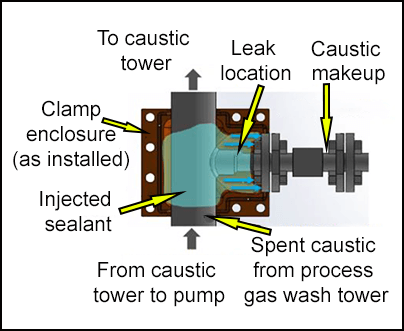

A team were installing a clamp on a pipe at the tee joint of a process gas compressor (PGC) caustic wash tower fresh caustic makeup line.

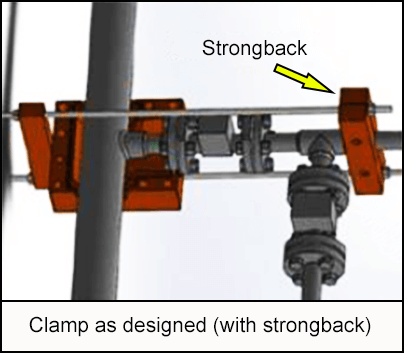

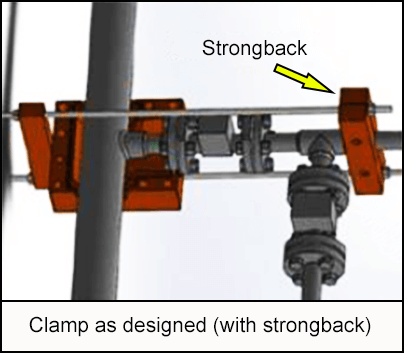

The clamp was placed on the tee connection without installing the strongback component.

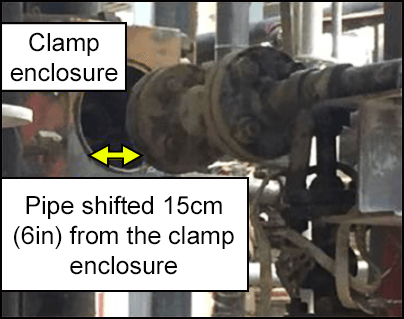

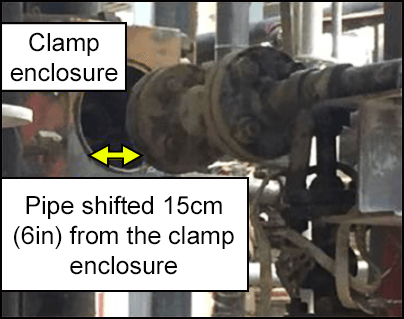

When sealant was injected into the clamp enclosure, the piping overstressed and shifted from the enclosure (see image).

This resulted in loss of containment, allowing caustic and vapour to be released from the line.

Three workers were injured.

-

Why did it happen?

The team did not install the strongback component prior to injecting sealant. If installed correctly as per design, the clamp would have prevented pipe stress.

The team did not follow the documented processes. Strongback installation was included in the procedure for the task.

-

What did they learn?

Include verification steps in high-risk tasks to confirm precise execution (e.g. document the installation of all clamp components and sealing static pumping pressure).

Before starting work, confirm that workers understand, can explain the procedure in full and can describe how executions steps are verified.

Initiate ‘stop work’ procedure if there is a change to the work conditions. Assess if it is safe to continue.

-

Ask yourself or your crew

What factors could lead to pipe stress during today’s task?

What other hazards should you look out for when performing equipment installation?

Do your high-risk tasks include verification steps? If not, how do you ensure that all steps in the procedure have been followed?

What measures do we have in place for preventing this from happening here? How can we improve?

Add to homescreen

Content name

Select existing category:

Content name

New collection

Edit collection

What happened?

A team were installing a clamp on a pipe at the tee joint of a process gas compressor (PGC) caustic wash tower fresh caustic makeup line.

The clamp was placed on the tee connection without installing the strongback component.

When sealant was injected into the clamp enclosure, the piping overstressed and shifted from the enclosure (see image).

This resulted in loss of containment, allowing caustic and vapour to be released from the line.

Three workers were injured.

Why did it happen?

The team did not install the strongback component prior to injecting sealant. If installed correctly as per design, the clamp would have prevented pipe stress.

The team did not follow the documented processes. Strongback installation was included in the procedure for the task.

What did they learn?

Include verification steps in high-risk tasks to confirm precise execution (e.g. document the installation of all clamp components and sealing static pumping pressure).

Before starting work, confirm that workers understand, can explain the procedure in full and can describe how executions steps are verified.

Initiate ‘stop work’ procedure if there is a change to the work conditions. Assess if it is safe to continue.

Ask yourself or your crew

What factors could lead to pipe stress during today’s task?

What other hazards should you look out for when performing equipment installation?

Do your high-risk tasks include verification steps? If not, how do you ensure that all steps in the procedure have been followed?

What measures do we have in place for preventing this from happening here? How can we improve?

A team were installing a clamp on a pipe at the tee joint of a process gas compressor (PGC) caustic wash tower fresh caustic makeup line. When sealant was injected into the clamp enclosure, the piping overstressed and shifted from the enclosure, allowing caustic and vapour to be released from the line.