-

What happened?

A rig crane was unloading a food container.

The crane was fitted with two wires:

- One heavy-duty wire for unloading.

- One smaller wire hanging 6 metres (19.5 feet) below the crane boom, which was not required for this operation.

The rig crane attempted to lift the container, but it was too heavy, so it was returned to deck.

The lifting wire was disconnected by the deck crew.

Upon disconnection, and before the deck crew had cleared the area, the crane driver started to retrieve the smaller wire.

The wire heaved all the way up to the crane boom and the hook block came into contact with the end of the boom.

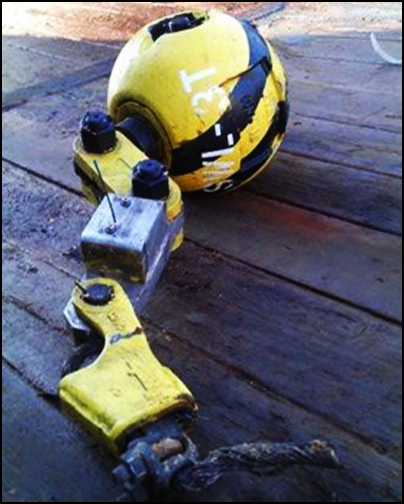

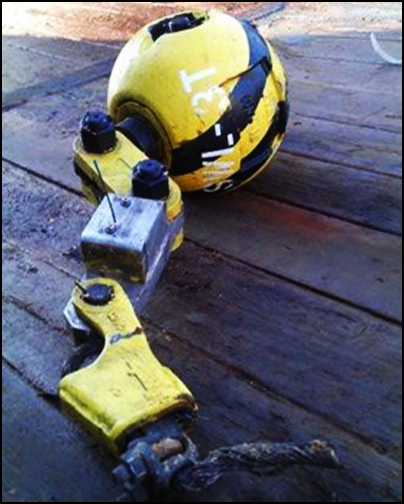

The wire parted and the hook block fell 15 metres (49 feet) to the deck below.

The dropped object landed in close proximity to the crew. Fortunately, there were no injuries.

The crane block destroyed sections of wood planks on main deck and damaged the bunker tank top underneath.

-

Why did it happen?

The crane driver retrieved the smaller wire instead of retrieving the main lifting wire.

The rig crane’s limit switches were not fully operational, allowing the hook block to be heaved all the way up to the boom.

-

What did they learn?

Emphasise the importance of a clear deck policy, and to remain clear of any suspended load or works.

Ensure all equipment is mechanically fit for purpose (e.g. limit switches are tested).

Ensure lines of communication are clear to enable safe operational practices.

Confirm that all workers understand and are prepared to exercise the ‘stop work policy’ if required.

Remind all workers to be aware of how human error can affect works around them.

-

Ask yourself or your crew

What checks do you perform on your equipment before lifting operations?

How do you test the limit switches on your crane? How often should you conduct these tests?

How do you execute a ‘stop work policy’?

What are the human errors that can occur during lifting operations? What other hazards are there?

How can we prevent something similar from happening on our site?

Add to homescreen

Content name

Select existing category:

Content name

New collection

Edit collection

What happened?

A rig crane was unloading a food container.

The crane was fitted with two wires:

- One heavy-duty wire for unloading.

- One smaller wire hanging 6 metres (19.5 feet) below the crane boom, which was not required for this operation.

The rig crane attempted to lift the container, but it was too heavy, so it was returned to deck.

The lifting wire was disconnected by the deck crew.

Upon disconnection, and before the deck crew had cleared the area, the crane driver started to retrieve the smaller wire.

The wire heaved all the way up to the crane boom and the hook block came into contact with the end of the boom.

The wire parted and the hook block fell 15 metres (49 feet) to the deck below.

The dropped object landed in close proximity to the crew. Fortunately, there were no injuries.

The crane block destroyed sections of wood planks on main deck and damaged the bunker tank top underneath.

Why did it happen?

The crane driver retrieved the smaller wire instead of retrieving the main lifting wire.

The rig crane’s limit switches were not fully operational, allowing the hook block to be heaved all the way up to the boom.

What did they learn?

Emphasise the importance of a clear deck policy, and to remain clear of any suspended load or works.

Ensure all equipment is mechanically fit for purpose (e.g. limit switches are tested).

Ensure lines of communication are clear to enable safe operational practices.

Confirm that all workers understand and are prepared to exercise the ‘stop work policy’ if required.

Remind all workers to be aware of how human error can affect works around them.

Ask yourself or your crew

What checks do you perform on your equipment before lifting operations?

How do you test the limit switches on your crane? How often should you conduct these tests?

How do you execute a ‘stop work policy’?

What are the human errors that can occur during lifting operations? What other hazards are there?

How can we prevent something similar from happening on our site?

A crane driver was retrieving a wire when it was heaved up to the crane boom and the hook block hit the end of the boom. The wire parted and the hook block fell 15 metres (49 feet) to the deck below.