-

What happened?

Workers were repairing the hydraulic arm of a remotely operated underwater vehicle (ROV) manipulator.

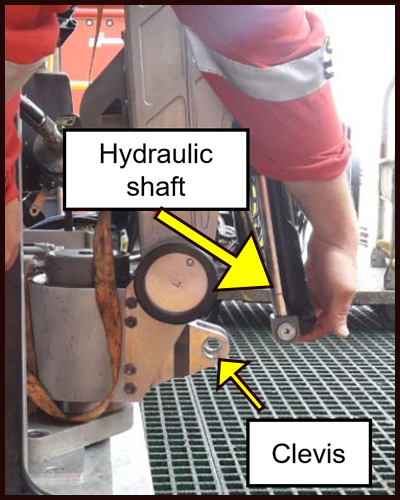

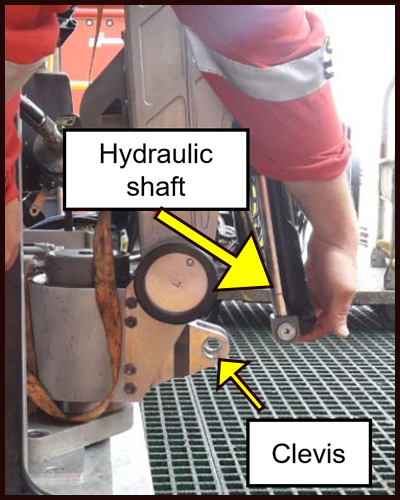

The person involved was trying to adjust the position of the piston to align holes to receive a shear pin.

They used their finger to confirm alignment of the clevis and hydraulic shaft holes.

The piston moved. Their left index finger was trapped, slicing off 1 cm of their finger.

-

Why did it happen?

The arm had been secured to the ROV using a cargo strap. However, the shoulder function had been enabled on the master arm to allow alignment of the clevis with the hydraulic shaft.

The person involved didn’t put his hand in a safe place before giving the instruction to the ROV supervisor to retract/extend the shaft in order for him to align the shaft and the clevis.

The technical manual was not reviewed before starting work, nor was any manual or procedure referred to when doing the task risk assessment.

The task risk assessment lacked detail – there was no reference to isolation.

-

What did they learn?

Isolation/lock-out/tag-out of system hydraulics related to work activity should be undertaken before starting work.

Follow the guidance and safety processes of technical manuals.

Task risk assessment should be relevant, suitable and sufficient to the task in hand. It should capture the potential risks related to inadvertent movement or catastrophic failure of hydraulic equipment.

Ensure that all personnel are at a safe distance from the testing area, so they are not exposed to harm or risk.

-

Ask yourself or your crew

How can something like this happen here?

What can we do to avoid working on equipment that is not isolated?

How do we know equipment has been safely isolated?

Has the task risk assessment captured all the risks of today’s task? How do we know?

Would you know what technical manuals to refer to when carrying out repairs and maintenance?

Add to homescreen

Content name

Select existing category:

Content name

New collection

Edit collection

What happened?

Workers were repairing the hydraulic arm of a remotely operated underwater vehicle (ROV) manipulator.

The person involved was trying to adjust the position of the piston to align holes to receive a shear pin.

They used their finger to confirm alignment of the clevis and hydraulic shaft holes.

The piston moved. Their left index finger was trapped, slicing off 1 cm of their finger.

Why did it happen?

The arm had been secured to the ROV using a cargo strap. However, the shoulder function had been enabled on the master arm to allow alignment of the clevis with the hydraulic shaft.

The person involved didn’t put his hand in a safe place before giving the instruction to the ROV supervisor to retract/extend the shaft in order for him to align the shaft and the clevis.

The technical manual was not reviewed before starting work, nor was any manual or procedure referred to when doing the task risk assessment.

The task risk assessment lacked detail – there was no reference to isolation.

What did they learn?

Isolation/lock-out/tag-out of system hydraulics related to work activity should be undertaken before starting work.

Follow the guidance and safety processes of technical manuals.

Task risk assessment should be relevant, suitable and sufficient to the task in hand. It should capture the potential risks related to inadvertent movement or catastrophic failure of hydraulic equipment.

Ensure that all personnel are at a safe distance from the testing area, so they are not exposed to harm or risk.

Ask yourself or your crew

How can something like this happen here?

What can we do to avoid working on equipment that is not isolated?

How do we know equipment has been safely isolated?

Has the task risk assessment captured all the risks of today’s task? How do we know?

Would you know what technical manuals to refer to when carrying out repairs and maintenance?

Workers were repairing the hydraulic arm of a remotely operated underwater vehicle (ROV) manipulator. The piston moved. Their left index finger was trapped, slicing off 1 cm of their finger.