-

What happened?

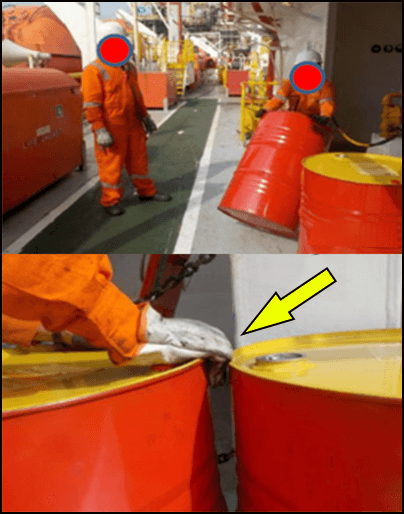

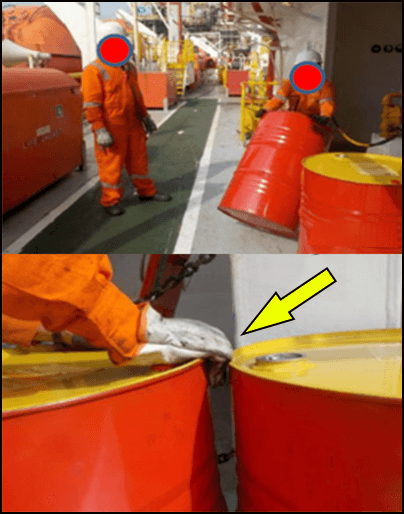

Workers were moving 200l (44gal) oil drums from a container using a pallet truck.

A worker trapped his finger between two drums, but continued work.

Once the operation was over he reported the incident to the medic, took painkillers and resumed work.

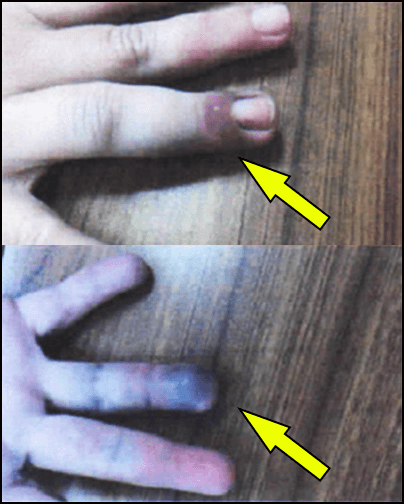

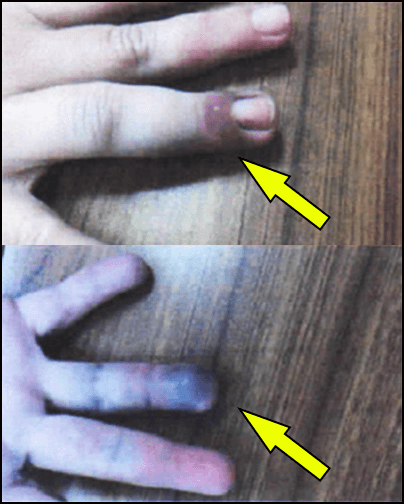

At the end of shift, the worker removed his safety gloves and saw his finger had turned purple and black with bruising.

He was disembarked and received an x-ray in a local hospital, which revealed he had suffered a fracture.

The worker was considered unfit to work for 15 days.

-

Why did it happen?

No engineered mechanism to make this operation safer or hands-free.

No procedures in place for this kind of work.

Risks were seen as tolerable – the workers were complacent about safety.

The worker did not stop working and no one else intervened to stop the job.

Incident was not reported to shore-based management in a timely and appropriate way.

-

What did they learn?

Consider implementing engineered controls (drum trolley and wheel) to remove people from the hazard.

When manual handling is required, discuss the adequate handling method before starting work.

Risk assessments (RA) and toolbox talks (TBT) should be carried out for all jobs to ensure all workers involved are aware of the risks.

All hazards identified during RA/TBT should be mitigated before starting work.

Personnel should report incidents/accidents to management in a timely and appropriate way.

-

Ask yourself or your crew

How do we move oil drums on our site?

- Can we improve our procedures for this operation? How?

What are the engineered/hands-free mechanisms that could make your operations safer?

How should you report an incident/accident on site?

What risks are seen as tolerable?

- What should you do if you perceive a tolerable risk as high risk?

Add to homescreen

Content name

Select existing category:

Content name

New collection

Edit collection

What happened?

Workers were moving 200l (44gal) oil drums from a container using a pallet truck.

A worker trapped his finger between two drums, but continued work.

Once the operation was over he reported the incident to the medic, took painkillers and resumed work.

At the end of shift, the worker removed his safety gloves and saw his finger had turned purple and black with bruising.

He was disembarked and received an x-ray in a local hospital, which revealed he had suffered a fracture.

The worker was considered unfit to work for 15 days.

Why did it happen?

No engineered mechanism to make this operation safer or hands-free.

No procedures in place for this kind of work.

Risks were seen as tolerable – the workers were complacent about safety.

The worker did not stop working and no one else intervened to stop the job.

Incident was not reported to shore-based management in a timely and appropriate way.

What did they learn?

Consider implementing engineered controls (drum trolley and wheel) to remove people from the hazard.

When manual handling is required, discuss the adequate handling method before starting work.

Risk assessments (RA) and toolbox talks (TBT) should be carried out for all jobs to ensure all workers involved are aware of the risks.

All hazards identified during RA/TBT should be mitigated before starting work.

Personnel should report incidents/accidents to management in a timely and appropriate way.

Ask yourself or your crew

How do we move oil drums on our site?

- Can we improve our procedures for this operation? How?

What are the engineered/hands-free mechanisms that could make your operations safer?

How should you report an incident/accident on site?

What risks are seen as tolerable?

- What should you do if you perceive a tolerable risk as high risk?

Workers were moving 200l (44gal) oil drums from a container using a pallet truck. A worker trapped his finger between two drums. He continued work, but it was later discovered he had suffered a fracture. The worker was considered unfit to work for 15 days.