-

What happened?

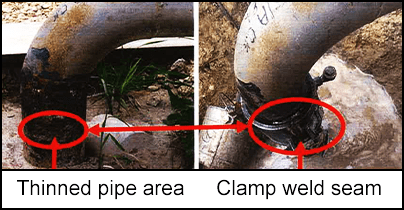

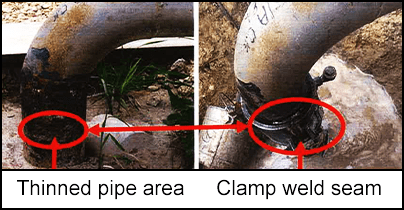

External corrosion was identified on a 6” (15 cm) liquid petroleum gas (LPG) line during an inspection.

Radiographic testing measurements indicated the line was not fit for service.

However, the line was shared by multiple units and would have required a multiple unit shutdown to remove from service.

It was decided to use weld-on clamps, as it seemed to provide a long-term repair to the thinned pipe.

Epoxy was poured into the clamp before welding in attempt to protect the thinned area during welding.

While welding the clamp, an LPG flame ignited at the top of the clamp.

Standby fire brigade members quickly extinguished the fire.

-

Why did it happen?

The long seam of the clamp was right over the thinned spot on the pipe. With the addition of heat during welding, the epoxy degraded, the metal expanded, and the pipe ruptured.

The clamp was incorrectly classified as a long term/permanent repair.

The decision to fill the clamp with epoxy was unusual:

- The potential for the epoxy to degrade was not fully understood.

- The manufacturer did not explain that heat input should be limited, and no one requested more information before starting work.

-

What did they learn?

Obtain additional approval for any high-risk work for temporary repairs.

Check the fit-up for repairs prior to welding (including sign-off).

Review and update the job safety plan for hot welding jobs to include:

- additional heat resistant personal protective equipment (PPE)

- gas testing the area and equipment

- multiple means of egress

- fire brigade on standby/charged fire hose

Ensure the definition of temporary repairs vs. permanent repairs is clear.

-

Ask yourself or your crew

What would you have done in this situation?

How would you make sure that any decisions which seem unusual, are correct?

Should work have been halted until a permanent repair could be implemented?

Do any of your work tasks have a fire/flammable risk?

Add to homescreen

Content name

Select existing category:

Content name

New collection

Edit collection

What happened?

External corrosion was identified on a 6” (15 cm) liquid petroleum gas (LPG) line during an inspection.

Radiographic testing measurements indicated the line was not fit for service.

However, the line was shared by multiple units and would have required a multiple unit shutdown to remove from service.

It was decided to use weld-on clamps, as it seemed to provide a long-term repair to the thinned pipe.

Epoxy was poured into the clamp before welding in attempt to protect the thinned area during welding.

While welding the clamp, an LPG flame ignited at the top of the clamp.

Standby fire brigade members quickly extinguished the fire.

Why did it happen?

The long seam of the clamp was right over the thinned spot on the pipe. With the addition of heat during welding, the epoxy degraded, the metal expanded, and the pipe ruptured.

The clamp was incorrectly classified as a long term/permanent repair.

The decision to fill the clamp with epoxy was unusual:

- The potential for the epoxy to degrade was not fully understood.

- The manufacturer did not explain that heat input should be limited, and no one requested more information before starting work.

What did they learn?

Obtain additional approval for any high-risk work for temporary repairs.

Check the fit-up for repairs prior to welding (including sign-off).

Review and update the job safety plan for hot welding jobs to include:

- additional heat resistant personal protective equipment (PPE)

- gas testing the area and equipment

- multiple means of egress

- fire brigade on standby/charged fire hose

Ensure the definition of temporary repairs vs. permanent repairs is clear.

Ask yourself or your crew

What would you have done in this situation?

How would you make sure that any decisions which seem unusual, are correct?

Should work have been halted until a permanent repair could be implemented?

Do any of your work tasks have a fire/flammable risk?

Corrosion was identified on a liquefied petroleum gas (LPG) line during inspection. Whilst welding the clamp to repair the pipe, an LPG flame ignited on the clamp.