-

What happened?

A free fall arrestor (FFA) system was installed over 2 years ago on the 4 coke drums of a coker unit.

FFA was equipped with 4 dampers at lower elevation (35 feet/10 metres) and 4 dampers at higher elevation (80 feet/24 metres).

A 27 lb/12 kg cable damper fell from the structure and was found on the ground.

No one was injured.

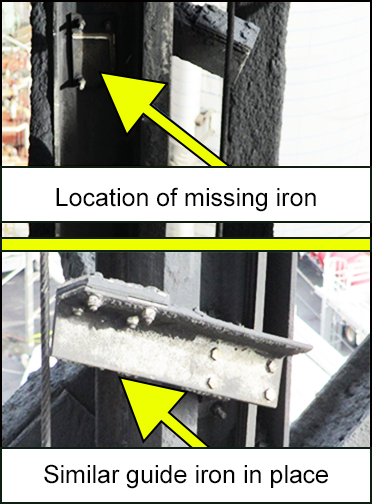

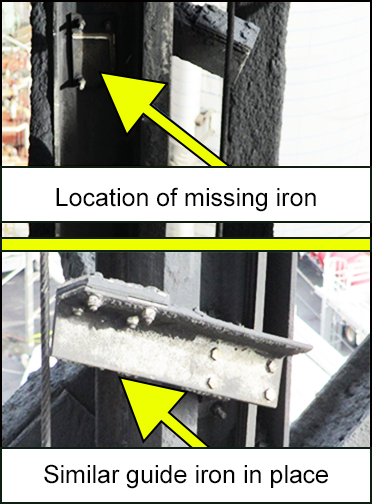

Since the installation, the crosshead assembly has come out from inside the crosshead guiderails repeatedly (at least 7 times).

-

Why did it happen?

The damper was designed to reduce the movement of the free fall arrestor (FFA) cables during high wind.

Dampers were not needed at the incident location. Once installed, they could not be easily maintained due to difficulty to access.

3 out of 4 drums had issues keeping the cables tensioned correctly as per manufacture’s recommendations.

With low tension, the cables whipped around in the wind, damaging whisker limit switches or wrapping around cable dampers and restricting movement of the Ideco swivel.

-

What did they learn?

Work with manufacture to establish preventive maintenance for the equipment.

Mechanics and operators should be trained by manufacture on performing preventive maintenance, cable tensioning, gripper box testing, and limit switch monitoring.

The free fall arrestor (FFA) installation should be audited regularly to ensure the monitoring of:

- cable tension (2000 lb/910 kg)

- gripper boxes

- periodic static testing (every 6 months)

- latching mechanism system maintenance

- condition of the FFA cable and anchors

Upgrade anchors to wire rope clamp. If slipping still occurs, upgrade to the newest design.

Use system dampers in high wind areas as intended.

-

Ask yourself or your crew

How can something like this happen here? What can you do to prevent it?

What equipment do we have that we cannot maintain (e.g. hard to reach, unneeded or unused equipment)?

Is this equipment really ‘out of sight, out of mind?’ What could happen?

How can we maintain proper cable tensioning?

Add to homescreen

Content name

Select existing category:

Content name

New collection

Edit collection

What happened?

A free fall arrestor (FFA) system was installed over 2 years ago on the 4 coke drums of a coker unit.

FFA was equipped with 4 dampers at lower elevation (35 feet/10 metres) and 4 dampers at higher elevation (80 feet/24 metres).

A 27 lb/12 kg cable damper fell from the structure and was found on the ground.

No one was injured.

Since the installation, the crosshead assembly has come out from inside the crosshead guiderails repeatedly (at least 7 times).

Why did it happen?

The damper was designed to reduce the movement of the free fall arrestor (FFA) cables during high wind.

Dampers were not needed at the incident location. Once installed, they could not be easily maintained due to difficulty to access.

3 out of 4 drums had issues keeping the cables tensioned correctly as per manufacture’s recommendations.

With low tension, the cables whipped around in the wind, damaging whisker limit switches or wrapping around cable dampers and restricting movement of the Ideco swivel.

What did they learn?

Work with manufacture to establish preventive maintenance for the equipment.

Mechanics and operators should be trained by manufacture on performing preventive maintenance, cable tensioning, gripper box testing, and limit switch monitoring.

The free fall arrestor (FFA) installation should be audited regularly to ensure the monitoring of:

- cable tension (2000 lb/910 kg)

- gripper boxes

- periodic static testing (every 6 months)

- latching mechanism system maintenance

- condition of the FFA cable and anchors

Upgrade anchors to wire rope clamp. If slipping still occurs, upgrade to the newest design.

Use system dampers in high wind areas as intended.

Ask yourself or your crew

How can something like this happen here? What can you do to prevent it?

What equipment do we have that we cannot maintain (e.g. hard to reach, unneeded or unused equipment)?

Is this equipment really ‘out of sight, out of mind?’ What could happen?

How can we maintain proper cable tensioning?

A 27 lb/12 kg cable damper fell from a fall arrestor and was found on the ground. The damper was designed to reduce the movement of the free fall arrestor (FFA) cables during high wind.