-

What happened?

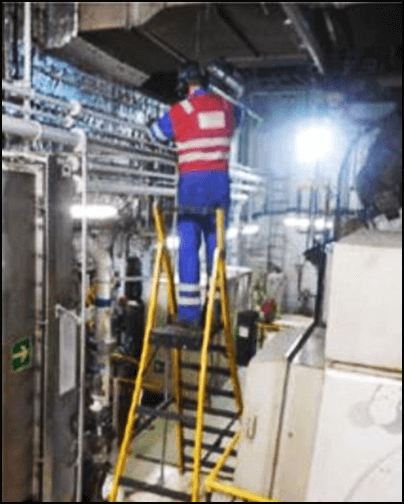

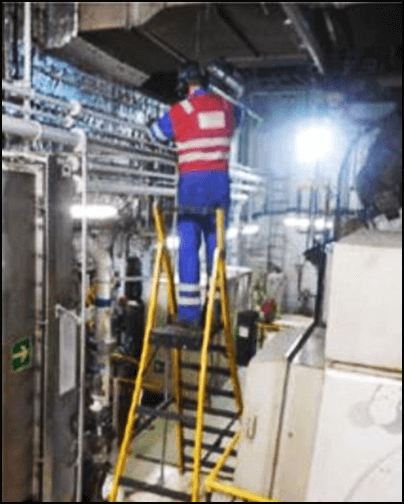

Vessel engineers were installing a support frame for spray protection curtains around an evaporator in the engine room.

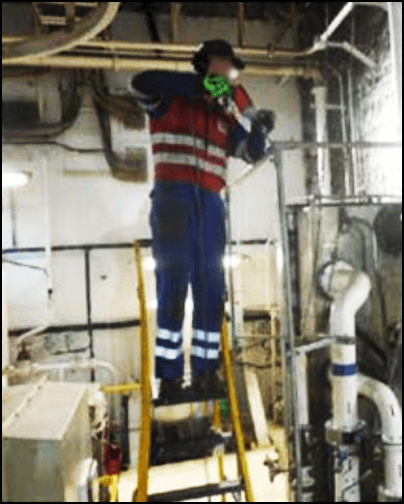

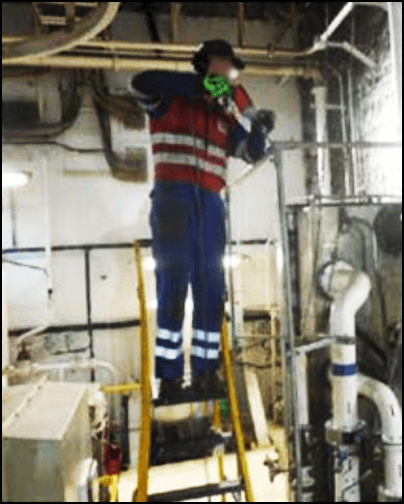

An engineer was working on a designated working at height platform with a power drill.

Whilst the engineer was drilling, the drill bit snagged within the metal tubing of the supporting frame.

This caused the pistol drill to kick back, and spin in a clockwise direction.

As the drill spun, the pistol grip was pulled from the engineer’s right hand.

The pistol drill continued to rotate, then knocked against their right wrist, causing injury.

-

Why did it happen?

The task was being carried out at height, making it difficult to drill the hole in the correct position. The engineer had to work in a position which caused the drill to snag.

Lack of active supervision.

The job was not recognised as a ‘working at height’ task:

- The toolbox talk only looked at potential hand injuries and slip/trip hazards, but not the associated risks of working with powered tools at height.

- If correctly identified as ‘working from height’ task, the holes could have been pre-drilled at deck level.

Permit to work (PTW) and job risk assessment (JRA) were not considered necessary as a similar job had been performed previously.

- Enginners failed to recognise the significant difference in height between the two jobs as being a risk factor.

-

What did they learn?

Ensure the correct tools are used, and under the correct conditions.

- Correct tools and equipment used in the wrong conditions can still result in an incident.

Ensure stepladders with designated working platforms have handrails and securing chains in position.

Tasks requiring ladders, working platforms or alternate access solutions should be checked to make sure the correct level of work control is applied.

Manage changes correctly so that routine tasks do not become hazardous.

-

Ask yourself or your crew

What do you class as ‘working at height’?

Think of a time when working at height has made your task more difficult. How was it different and what happened/could happen?

Do you feel your tasks have enough supervision? If not, what should you do?

What can you do if you don’t have the correct PTW and JRA for your tasks?

Add to homescreen

Content name

Select existing category:

Content name

New collection

Edit collection

What happened?

Vessel engineers were installing a support frame for spray protection curtains around an evaporator in the engine room.

An engineer was working on a designated working at height platform with a power drill.

Whilst the engineer was drilling, the drill bit snagged within the metal tubing of the supporting frame.

This caused the pistol drill to kick back, and spin in a clockwise direction.

As the drill spun, the pistol grip was pulled from the engineer’s right hand.

The pistol drill continued to rotate, then knocked against their right wrist, causing injury.

Why did it happen?

The task was being carried out at height, making it difficult to drill the hole in the correct position. The engineer had to work in a position which caused the drill to snag.

Lack of active supervision.

The job was not recognised as a ‘working at height’ task:

- The toolbox talk only looked at potential hand injuries and slip/trip hazards, but not the associated risks of working with powered tools at height.

- If correctly identified as ‘working from height’ task, the holes could have been pre-drilled at deck level.

Permit to work (PTW) and job risk assessment (JRA) were not considered necessary as a similar job had been performed previously.

- Enginners failed to recognise the significant difference in height between the two jobs as being a risk factor.

What did they learn?

Ensure the correct tools are used, and under the correct conditions.

- Correct tools and equipment used in the wrong conditions can still result in an incident.

Ensure stepladders with designated working platforms have handrails and securing chains in position.

Tasks requiring ladders, working platforms or alternate access solutions should be checked to make sure the correct level of work control is applied.

Manage changes correctly so that routine tasks do not become hazardous.

Ask yourself or your crew

What do you class as ‘working at height’?

Think of a time when working at height has made your task more difficult. How was it different and what happened/could happen?

Do you feel your tasks have enough supervision? If not, what should you do?

What can you do if you don’t have the correct PTW and JRA for your tasks?

Vessel engineers were installing a support frame for spray protection curtains in an engine room. Whilst the engineer was drilling, the drill bit snagged, causing the pistol drill to kick back and knock against their right wrist, causing injury.