-

What happened?

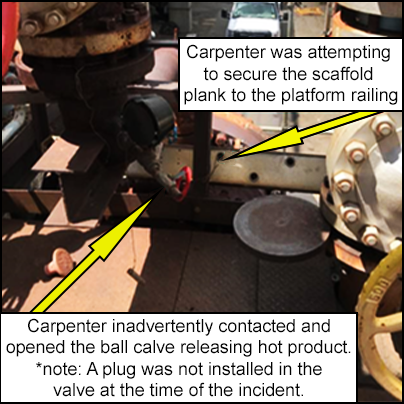

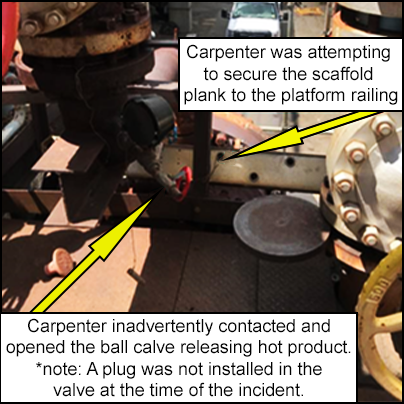

Carpenters were modifying a scaffold for access to the channel on an exchanger for maintenance.

A worker was backing out of the tight work area when his tool belt caught on a ½ inch (1 cm) quarter turn ball valve.

The valve opened and hot naphtha was released from the open bleeder.

The worker received first and second degree burns to thighs and hand.

-

Why did it happen?

The bleeder plug was tethered to the valve, but not installed.

- The missing plug was not noticed during the joint jobsite visit (JJSV) or the job safety analysis (JSA).

- The JSA was not carried out at the platform level.

The style of ball valve requires less force to open than a gate valve.

The line was in service at the time of the event.

The working area was very small and contained a lot of equipment.

The employee’s toolbelt had previously snagged on other equipment but was still considered low risk.

-

What did they learn?

Consider replacing the quarter turn ball bleeder valve with a gate bleeder valve and plug.

Evaluate the use of valves throughout sites, especially where they are a single isolation point for hazardous materials.

Ensure the JSA is carried out where the work will be taking place.

Take action to minimise hazards during job planning – including things that might be considered low risk.

Conduct an open-ended line survey. Consider updating the safety diary with equipment specific plug checks.

Determine if a spring can support is required for exchangers.

Ensure that the process and instrumentation diagrams accurately reflect what is built in the field.

-

Ask yourself or your crew

How do you check if the equipment you carry poses any risks – however small they might seem?

Is there any equipment that you work with which could be changed for something safer?

Do you know what is looked for/at during the JJSV or the JSA?

What PPE would a carpenter be wearing to do this job? Is it sufficient?

What are your procedures for working in tight spaces? Are they any different than working in normal conditions? If not, what could make it safer?

Add to homescreen

Content name

Select existing category:

Content name

New collection

Edit collection

What happened?

Carpenters were modifying a scaffold for access to the channel on an exchanger for maintenance.

A worker was backing out of the tight work area when his tool belt caught on a ½ inch (1 cm) quarter turn ball valve.

The valve opened and hot naphtha was released from the open bleeder.

The worker received first and second degree burns to thighs and hand.

Why did it happen?

The bleeder plug was tethered to the valve, but not installed.

- The missing plug was not noticed during the joint jobsite visit (JJSV) or the job safety analysis (JSA).

- The JSA was not carried out at the platform level.

The style of ball valve requires less force to open than a gate valve.

The line was in service at the time of the event.

The working area was very small and contained a lot of equipment.

The employee’s toolbelt had previously snagged on other equipment but was still considered low risk.

What did they learn?

Consider replacing the quarter turn ball bleeder valve with a gate bleeder valve and plug.

Evaluate the use of valves throughout sites, especially where they are a single isolation point for hazardous materials.

Ensure the JSA is carried out where the work will be taking place.

Take action to minimise hazards during job planning – including things that might be considered low risk.

Conduct an open-ended line survey. Consider updating the safety diary with equipment specific plug checks.

Determine if a spring can support is required for exchangers.

Ensure that the process and instrumentation diagrams accurately reflect what is built in the field.

Ask yourself or your crew

How do you check if the equipment you carry poses any risks – however small they might seem?

Is there any equipment that you work with which could be changed for something safer?

Do you know what is looked for/at during the JJSV or the JSA?

What PPE would a carpenter be wearing to do this job? Is it sufficient?

What are your procedures for working in tight spaces? Are they any different than working in normal conditions? If not, what could make it safer?

A carpenter was working on scaffolding when his toolbelt caught and opened a ball valve. Hot naphtha was released through the open bleeder, causing first and second degree burns to the carpenter.