-

What happened?

Outrigger feet give safe support to prevent mobile plant from overturning (such as elevating work platforms (EWP), mobile cranes, concrete placement booms and telehandlers).

A number of incidents have occurred where mobile plant using outriggers have overturned.

When a 70m (230ft) travel tower EWP overturned, one worker lost their life.

-

Why did it happen?

There are a number of reasons why these incidents occur:

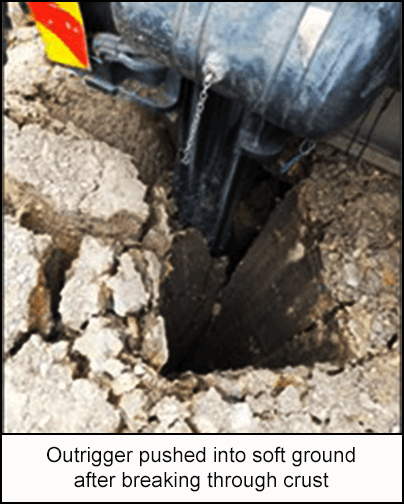

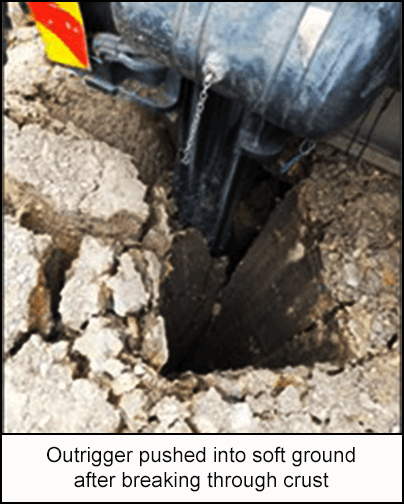

- Soft ground (often disguised by surface crust).

- Ground subsidence.

- The area of timbers or other pads under the outrigger feet not suitable for the ground conditions.

- Outrigger feet not being level.

- Uneven pressure applied to the ground, such as when outrigger pads or timbers bend.

- Increased loading on the outrigger (when the boom is directly above it or the boom is being loaded).

- Sinking of an outrigger pad while the unit is being operated.

- Short legging of an outrigger where the equipment is not designed for short legging.

-

What did they learn?

Follow operating instructions from the mobile plant manufacturer. If these are not available, a geotechnical engineer should be used to ensure ground support is sufficient.

The specialist should assess the ground, and specify suitable control measures (i.e. ground preparation with crushed rock, or the use of steel bog mats under the outrigger feet).

Where the site is made up of fill (rubble), the ground may not be as sturdy as it seems.

Operators should receive training, so they know what ground support is needed.

If the operator is unsure if the ground is suitable, they should seek further advice from a competent person (such as a geotechnical engineer) before starting work.

Procedures for checking the outrigger packing based on the EWP specifications and site conditions should be documented.

Procedures should reference the manufacturer's information on loading applied to the ground and the expected bearing capacity of the site.

Continually monitor outriggers during operation so that work can be stopped safely if needed.

-

Ask yourself or your crew

How can something like this happen here?

If our mobile plant overturned, what could the consequences be?

How do you know the ground is stable?

Whose responsibility is it to check the ground is stable?

How confident would you be to initiate ‘stop work’ if you felt the ground was unsafe?

Add to homescreen

Content name

Select existing category:

Content name

New collection

Edit collection

What happened?

Outrigger feet give safe support to prevent mobile plant from overturning (such as elevating work platforms (EWP), mobile cranes, concrete placement booms and telehandlers).

A number of incidents have occurred where mobile plant using outriggers have overturned.

When a 70m (230ft) travel tower EWP overturned, one worker lost their life.

Why did it happen?

There are a number of reasons why these incidents occur:

- Soft ground (often disguised by surface crust).

- Ground subsidence.

- The area of timbers or other pads under the outrigger feet not suitable for the ground conditions.

- Outrigger feet not being level.

- Uneven pressure applied to the ground, such as when outrigger pads or timbers bend.

- Increased loading on the outrigger (when the boom is directly above it or the boom is being loaded).

- Sinking of an outrigger pad while the unit is being operated.

- Short legging of an outrigger where the equipment is not designed for short legging.

What did they learn?

Follow operating instructions from the mobile plant manufacturer. If these are not available, a geotechnical engineer should be used to ensure ground support is sufficient.

The specialist should assess the ground, and specify suitable control measures (i.e. ground preparation with crushed rock, or the use of steel bog mats under the outrigger feet).

Where the site is made up of fill (rubble), the ground may not be as sturdy as it seems.

Operators should receive training, so they know what ground support is needed.

If the operator is unsure if the ground is suitable, they should seek further advice from a competent person (such as a geotechnical engineer) before starting work.

Procedures for checking the outrigger packing based on the EWP specifications and site conditions should be documented.

Procedures should reference the manufacturer's information on loading applied to the ground and the expected bearing capacity of the site.

Continually monitor outriggers during operation so that work can be stopped safely if needed.

Ask yourself or your crew

How can something like this happen here?

If our mobile plant overturned, what could the consequences be?

How do you know the ground is stable?

Whose responsibility is it to check the ground is stable?

How confident would you be to initiate ‘stop work’ if you felt the ground was unsafe?

A number of incidents have occurred where mobile plant using outriggers have overturned. When a 70m (230ft) travel tower EWP overturned, one worker lost their life.