-

What happened?

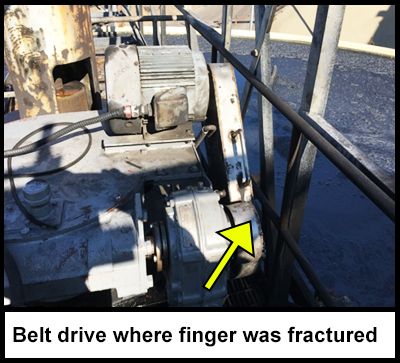

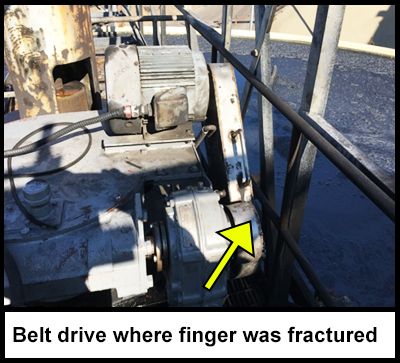

A mechanic and labourer were replacing two broken drive belts on an electric motor.

The mechanic asked the labourer to release tension on the spring by hand.

The mechanic then radioed operations to say he was going to attempt to start the motor.

The labourer overheard the radio communication but could not move his hands away in time.

As the motor started, the drive belts came off and fractured the labourer's index finger.

-

Why did it happen?

They did not replace the machine guard before energising equipment.

Poor communication: the mechanic did not give a verbal warning the motor was about to start.

They did not use lockout-tagout and work was not properly authorised.

They were rushing to avoid a 24 hour shutdown. It was the last day before a holiday break.

-

What did they learn?

Watch out for colleagues. Make sure they are not in the line of fire.

Importance of communication: give verbal ‘stand clear’ warning, and wait for a repeat-back. Use 3-way communication.

Follow work authorisation and lockout-tagout practices.

Do not rush. Take the time to do it safely.

-

Ask yourself or your crew

What other actions could have been taken?

Why do you think the mechanic did not warn the labourer?

How well do you think we communicate as team when working? What can we improve?

Think of a time you rushed to get work complete. What could have gone wrong?

Add to homescreen

Content name

Select existing category:

Content name

New collection

Edit collection

What happened?

A mechanic and labourer were replacing two broken drive belts on an electric motor.

The mechanic asked the labourer to release tension on the spring by hand.

The mechanic then radioed operations to say he was going to attempt to start the motor.

The labourer overheard the radio communication but could not move his hands away in time.

As the motor started, the drive belts came off and fractured the labourer's index finger.

Why did it happen?

They did not replace the machine guard before energising equipment.

Poor communication: the mechanic did not give a verbal warning the motor was about to start.

They did not use lockout-tagout and work was not properly authorised.

They were rushing to avoid a 24 hour shutdown. It was the last day before a holiday break.

What did they learn?

Watch out for colleagues. Make sure they are not in the line of fire.

Importance of communication: give verbal ‘stand clear’ warning, and wait for a repeat-back. Use 3-way communication.

Follow work authorisation and lockout-tagout practices.

Do not rush. Take the time to do it safely.

Ask yourself or your crew

What other actions could have been taken?

Why do you think the mechanic did not warn the labourer?

How well do you think we communicate as team when working? What can we improve?

Think of a time you rushed to get work complete. What could have gone wrong?

A mechanic and labourer were replacing two broken drive belts on an electric motor. As the motor started, the drive belts came off and fractured the labourer’s index finger.