-

What happened?

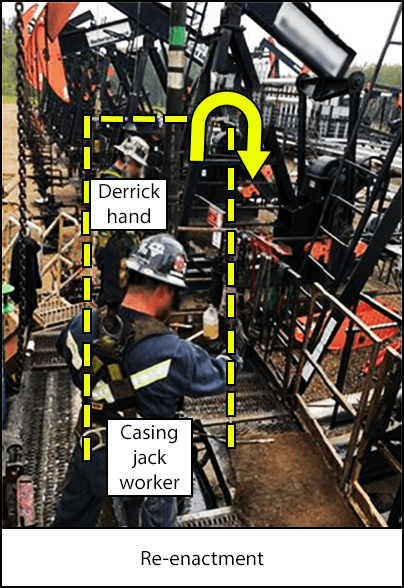

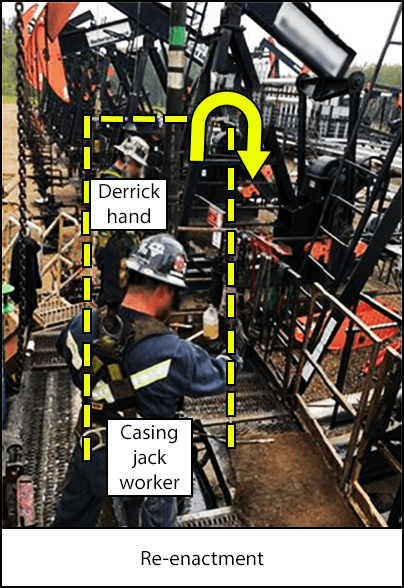

Workers were enlarging a casing restriction during rig up.

A casing jack unit weighing 907kg (2,000lbs) and 2.5m (8ft) tall was installed on a well using a mobile crane.

Workers were unable to enlarge the casing restriction, so they decided to rig out the jacks.

They removed the bolts securing the casing jacks to the well, without securing the casing jack overhead.

A worker was manually rotating the jacks when the casing unit fell 2m (7ft) to the ground.

The incident could have been fatal.

-

Why did it happen?

Casing jack was not secured overhead before removing securing bolts as required by procedure.

Safety procedure was not followed - procedure recognised the hazards of stored energy of top-heavy equipment.

Insufficient supervision - driller was not actively supervising the task an, nor was the well site supervisor who was distracted organising tools for the next day.

Job safety analysis (JSA) rig out meeting had not been held before workers started the task.

Hazard of casing jacks falling was not identified in the JSA (which included spotting equipment, rig up and casing jack operation).

-

What did they learn?

Workers should follow documented procedures.

Ensure effective supervision is in place during critical work tasks.

Hold safety talks before starting work to ensure workers understand the risks, mitigations, and safety standards.

Discuss exclusion zones for lifting and rigging activities and ensure compliance.

-

Ask yourself or your crew

What could they have done differently?

What is our procedure for enlarging casing restrictions?

How do you safely remove bolts securing casing jacks?

How do you know all hazards have been covered in the job safety analysis (JSA)?

How can this happen here? What measures do we have in place to prevent it from happening?

Add to homescreen

Content name

Select existing category:

Content name

New collection

Edit collection

What happened?

Workers were enlarging a casing restriction during rig up.

A casing jack unit weighing 907kg (2,000lbs) and 2.5m (8ft) tall was installed on a well using a mobile crane.

Workers were unable to enlarge the casing restriction, so they decided to rig out the jacks.

They removed the bolts securing the casing jacks to the well, without securing the casing jack overhead.

A worker was manually rotating the jacks when the casing unit fell 2m (7ft) to the ground.

The incident could have been fatal.

Why did it happen?

Casing jack was not secured overhead before removing securing bolts as required by procedure.

Safety procedure was not followed - procedure recognised the hazards of stored energy of top-heavy equipment.

Insufficient supervision - driller was not actively supervising the task an, nor was the well site supervisor who was distracted organising tools for the next day.

Job safety analysis (JSA) rig out meeting had not been held before workers started the task.

Hazard of casing jacks falling was not identified in the JSA (which included spotting equipment, rig up and casing jack operation).

What did they learn?

Workers should follow documented procedures.

Ensure effective supervision is in place during critical work tasks.

Hold safety talks before starting work to ensure workers understand the risks, mitigations, and safety standards.

Discuss exclusion zones for lifting and rigging activities and ensure compliance.

Ask yourself or your crew

What could they have done differently?

What is our procedure for enlarging casing restrictions?

How do you safely remove bolts securing casing jacks?

How do you know all hazards have been covered in the job safety analysis (JSA)?

How can this happen here? What measures do we have in place to prevent it from happening?

A casing jack unit was being installed on a well. The bolts securing the casing jacks to the wall were removed, but the casing jack was not secured. It fell 2m (7ft) to the ground below.