-

What happened?

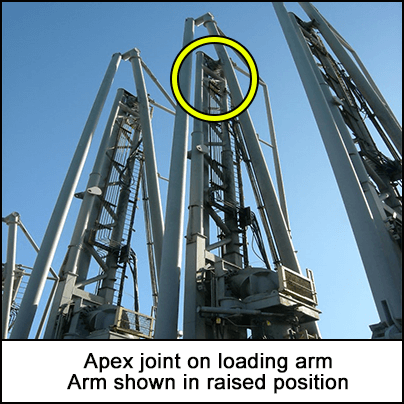

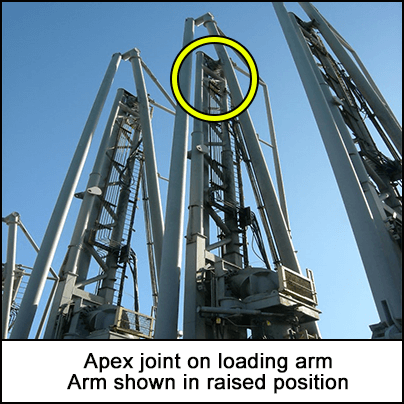

A vessel was being prepared for loading at a plant jetty.

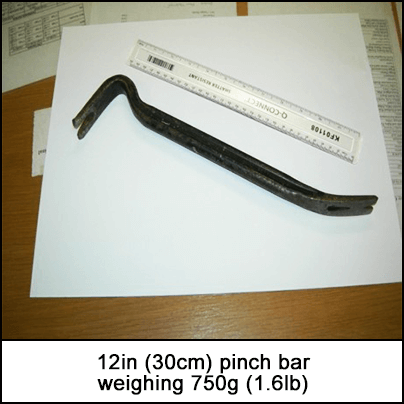

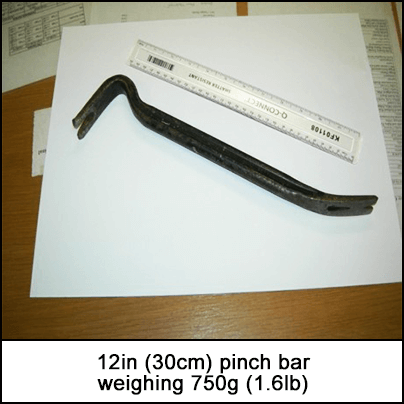

The operations team were extending a loading arm when a 12 inch (30cm) pinch bar weighing 750g (1.6 lb) fell 10 metres (33 feet) from the apex joint.

It landed on the deck of the vessel, 3 feet (1 metre) from where workers had previously been located, causing no injury or damage.

-

Why did it happen?

Maintenance work had been carried out the day before on the apex joint of the arm to replace a faulty seal.

- None of the personnel involved could remember using the tool and all tools were believed to be accounted for at the end of the task, and none seemed to be missing.

- Accounting for the tools and equipment relied on a sweep of the area rather than a positive tool check.

- The colour of the pinch bar meant that it would not have been easily visible against the colour of the loading arm.

The tool could have been left there by others. There is no identification on tooling (colour coding or etching) to aid traceability and tool kits are generally uncontrolled and available for anyone to access.

The permit for the maintenance work did not provide clear detail on tool control or accountability.

-

What did they learn?

Create a checklist for tools required while working at height, so that tools can be ticked off when the job is complete. Working at height tool checklist to be audited in 6 months to ensure its effectiveness.

Communicate to all those with the potential to work at height: only tools required for the task should be taken to site – to aid accounting of tools once the task is complete.

Recommendations should be implemented in conjunction with existing DROPS activities and ongoing behavioural standards activities.

-

Ask yourself or your crew

Have you ever discovered an object left at height?

What processes do we have in place to account for all tools after working at height? How can it be improved?

Do you carry extra tools to certain jobs? How can this be avoided, to make tool control easier?

What else can we do to prevent dropped objects?

Add to homescreen

Content name

Select existing category:

Content name

New collection

Edit collection

What happened?

A vessel was being prepared for loading at a plant jetty.

The operations team were extending a loading arm when a 12 inch (30cm) pinch bar weighing 750g (1.6 lb) fell 10 metres (33 feet) from the apex joint.

It landed on the deck of the vessel, 3 feet (1 metre) from where workers had previously been located, causing no injury or damage.

Why did it happen?

Maintenance work had been carried out the day before on the apex joint of the arm to replace a faulty seal.

- None of the personnel involved could remember using the tool and all tools were believed to be accounted for at the end of the task, and none seemed to be missing.

- Accounting for the tools and equipment relied on a sweep of the area rather than a positive tool check.

- The colour of the pinch bar meant that it would not have been easily visible against the colour of the loading arm.

The tool could have been left there by others. There is no identification on tooling (colour coding or etching) to aid traceability and tool kits are generally uncontrolled and available for anyone to access.

The permit for the maintenance work did not provide clear detail on tool control or accountability.

What did they learn?

Create a checklist for tools required while working at height, so that tools can be ticked off when the job is complete. Working at height tool checklist to be audited in 6 months to ensure its effectiveness.

Communicate to all those with the potential to work at height: only tools required for the task should be taken to site – to aid accounting of tools once the task is complete.

Recommendations should be implemented in conjunction with existing DROPS activities and ongoing behavioural standards activities.

Ask yourself or your crew

Have you ever discovered an object left at height?

What processes do we have in place to account for all tools after working at height? How can it be improved?

Do you carry extra tools to certain jobs? How can this be avoided, to make tool control easier?

What else can we do to prevent dropped objects?

A vessel was being prepared for loading at a plant jetty. The loading arm was being extended when a pinch bar fell from above.