-

What happened?

A technician was asked to repair two faulty dispenser pumps in a service station.

After fixing the first pump, 5 vehicles were refuelled.

An attendant noticed a leak at the bottom of the pump and reported it to the technician.

When the technician was about to fix the pump again, the leaking product suddenly ignited.

The emergency shutdown button was immediately activated.

The technician and station attendants used fire extinguishers to stop the fire.

The technician received burns and required first aid onsite. The dispenser was damaged.

-

Why did it happen?

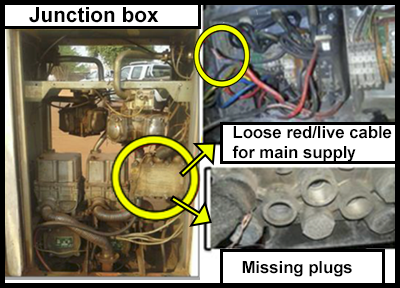

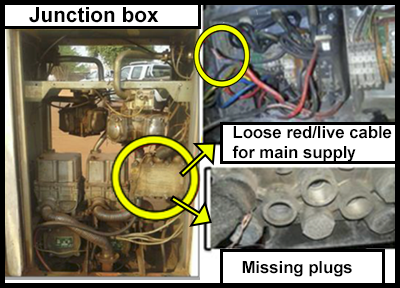

Junction box was open and electrical cables were not isolated.

Commissioning after intervention was not adequate.

The technician was underqualified.

Maintenance operation was not compliant with industry good practice.

Non-compliance with usual controls during preventive maintenance of the pump.

-

What did they learn?

1. Ensure that only qualified technicians (internal/contractors) perform repairs.

2. usual checks after maintenance operations (ATEX equipment, gasket).

3. Maintenance teams (internal or external) should perform checks of sensitive repair intervention compliance (by sampling).

4. If using contractors, verify their level of performance. Implement periodic competency reviews, verified by external annual reports.

5. If in doubt of a technician’s skill level, launch a contractor audit with onsite verification.

6. Perform inspections for contractors performing sensitive maintenance works, particularly ATEX equipment.

-

Ask yourself or your crew

What could have happened if the team could not stop the fire?

How can something like this happen here?

Would you perform a sensitive maintenance operation that you are not qualified for? Why?

What would you do on your site if you were asked to stop a work programs/task?

What would be good practice in this situation? How do you know if we follow good practice?

Add to homescreen

Content name

Select existing category:

Content name

New collection

Edit collection

What happened?

A technician was asked to repair two faulty dispenser pumps in a service station.

After fixing the first pump, 5 vehicles were refuelled.

An attendant noticed a leak at the bottom of the pump and reported it to the technician.

When the technician was about to fix the pump again, the leaking product suddenly ignited.

The emergency shutdown button was immediately activated.

The technician and station attendants used fire extinguishers to stop the fire.

The technician received burns and required first aid onsite. The dispenser was damaged.

Why did it happen?

Junction box was open and electrical cables were not isolated.

Commissioning after intervention was not adequate.

The technician was underqualified.

Maintenance operation was not compliant with industry good practice.

Non-compliance with usual controls during preventive maintenance of the pump.

What did they learn?

1. Ensure that only qualified technicians (internal/contractors) perform repairs.

2. usual checks after maintenance operations (ATEX equipment, gasket).

3. Maintenance teams (internal or external) should perform checks of sensitive repair intervention compliance (by sampling).

4. If using contractors, verify their level of performance. Implement periodic competency reviews, verified by external annual reports.

5. If in doubt of a technician’s skill level, launch a contractor audit with onsite verification.

6. Perform inspections for contractors performing sensitive maintenance works, particularly ATEX equipment.

Ask yourself or your crew

What could have happened if the team could not stop the fire?

How can something like this happen here?

Would you perform a sensitive maintenance operation that you are not qualified for? Why?

What would you do on your site if you were asked to stop a work programs/task?

What would be good practice in this situation? How do you know if we follow good practice?

After being fixed earlier in the day, a service pump was leaking. The station attendant asked the same contractor’s technician to have another look at it. When intervening, the leaking product ignited.