-

What happened?

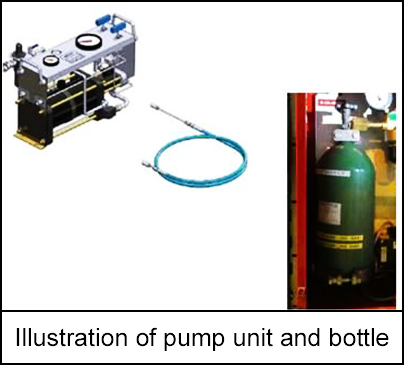

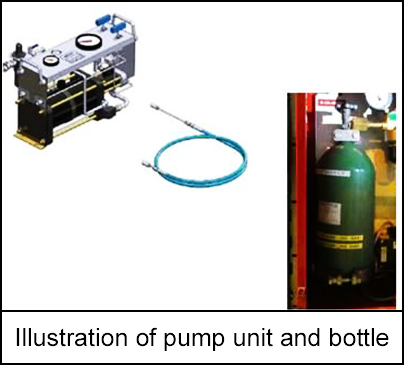

A portable booster pump with a capacity of 1000 bar was used to pressurise a 3.8 litre nitrogen bottle.

At 200 bar, the bottle exploded.

Two of the three personnel involved in the job were seriously injured.

The injured workers received first aid and were flown to shore for further treatment in hospital.

-

Why did it happen?

The pump had no pressure control, nor overpressure protection systems installed.

Only one pressure gauge was installed to monitor the pressure output.

-

What did they learn?

The use of mobile pumps should be risk assessed and covered by a permit to work.

Ensure that adequate safety barriers are in place. Staff should be situated at a safe distance from the pressurised equipment and outside the line of fire.

If the maximum delivery pressure of the mobile pump exceeds the design pressure of the equipment, a pressure relief valve should be fitted and set at 90% of the design pressure to prevent over pressurisation.

-

Ask yourself or your crew

What other actions could have been taken?

Before starting the work, how can you check if:

- the pressure output is adequately monitored?

- the equipment has been fitted with a pressure protection system (e.g. pressure relief valve)?

- the pressure protection system settings are in line with the equipment specifications?

What controls do we have in place to prevent this from happening here? How can we improve?

Add to homescreen

Content name

Select existing category:

Content name

New collection

Edit collection

What happened?

A portable booster pump with a capacity of 1000 bar was used to pressurise a 3.8 litre nitrogen bottle.

At 200 bar, the bottle exploded.

Two of the three personnel involved in the job were seriously injured.

The injured workers received first aid and were flown to shore for further treatment in hospital.

Why did it happen?

The pump had no pressure control, nor overpressure protection systems installed.

Only one pressure gauge was installed to monitor the pressure output.

What did they learn?

The use of mobile pumps should be risk assessed and covered by a permit to work.

Ensure that adequate safety barriers are in place. Staff should be situated at a safe distance from the pressurised equipment and outside the line of fire.

If the maximum delivery pressure of the mobile pump exceeds the design pressure of the equipment, a pressure relief valve should be fitted and set at 90% of the design pressure to prevent over pressurisation.

Ask yourself or your crew

What other actions could have been taken?

Before starting the work, how can you check if:

- the pressure output is adequately monitored?

- the equipment has been fitted with a pressure protection system (e.g. pressure relief valve)?

- the pressure protection system settings are in line with the equipment specifications?

What controls do we have in place to prevent this from happening here? How can we improve?

A portable booster pump with a capacity of 1000 bar was used to pressurise a 3.8 litre nitrogen bottle. At 200 bar, the bottle exploded. 2 workers were seriously injured.