-

What happened?

A worker was performing oversight of a saturated gas plant (SGP) chiller project.

The worker identified that there were no energy isolation or personal locks applied to the breaker (which was the power source for the project).

Electricians were actively working on the project at the time.

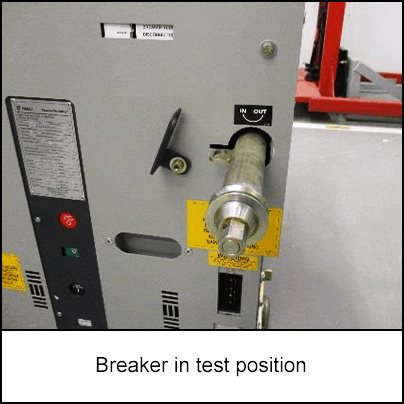

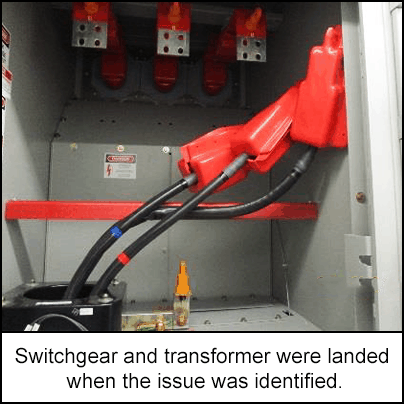

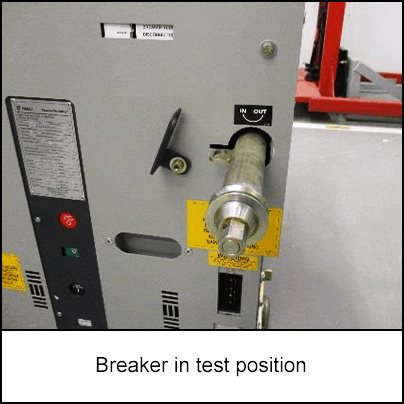

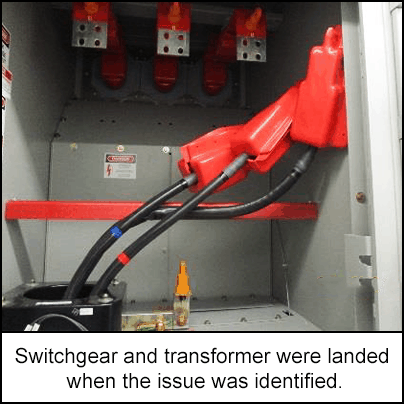

The feeder cable between the transformer and the sub-station was terminated, and the circuit breaker was in the cubicle in the test position but racked out.

The likelihood of injury was minimal, but the lockout – tag out – try out (LTT) energy isolation procedure was not in place during the task.

-

Why did it happen?

An energy isolation control package was never discussed or applied for the project.

The electrical contractor on the project did not think an isolation lock was necessary.

- It was considered sufficient that the air gap between the power source and the electrical system provided good enough energy isolation.

-

What did they learn?

Ensure good communication on energy isolation responsibilities between team members/other teams onsite. Ensure that there is a responsible project representative.

Modify the ‘lock out - tag out - try out’ policy to specify exactly how energy isolation is applied during all projects.

Complete energy isolation as included in the job safety analysis (JSA) and work permits (PtW).

During project planning, identify when to begin energy isolation and apply personal isolation locks. Communicate the findings so that it is clear for all involved.

-

Ask yourself or your crew

What checks do you need to do before starting work to ensure correct energy isolation procedures are in place? What should you do if you identify the measures in place are not enough to keep you safe?

Think of a time when you noticed that not all safety procedures have been followed? What did you do? Should you have done anything different?

How is the communication within your team/other teams working on site? How can it be improved so you’d all work in a safer manner?

Add to homescreen

Content name

Select existing category:

Content name

New collection

Edit collection

What happened?

A worker was performing oversight of a saturated gas plant (SGP) chiller project.

The worker identified that there were no energy isolation or personal locks applied to the breaker (which was the power source for the project).

Electricians were actively working on the project at the time.

The feeder cable between the transformer and the sub-station was terminated, and the circuit breaker was in the cubicle in the test position but racked out.

The likelihood of injury was minimal, but the lockout – tag out – try out (LTT) energy isolation procedure was not in place during the task.

Why did it happen?

An energy isolation control package was never discussed or applied for the project.

The electrical contractor on the project did not think an isolation lock was necessary.

- It was considered sufficient that the air gap between the power source and the electrical system provided good enough energy isolation.

What did they learn?

Ensure good communication on energy isolation responsibilities between team members/other teams onsite. Ensure that there is a responsible project representative.

Modify the ‘lock out - tag out - try out’ policy to specify exactly how energy isolation is applied during all projects.

Complete energy isolation as included in the job safety analysis (JSA) and work permits (PtW).

During project planning, identify when to begin energy isolation and apply personal isolation locks. Communicate the findings so that it is clear for all involved.

Ask yourself or your crew

What checks do you need to do before starting work to ensure correct energy isolation procedures are in place? What should you do if you identify the measures in place are not enough to keep you safe?

Think of a time when you noticed that not all safety procedures have been followed? What did you do? Should you have done anything different?

How is the communication within your team/other teams working on site? How can it be improved so you’d all work in a safer manner?

A worker was on a saturated gas plant (SGP) chiller project and identified that no energy isolation or personal locks were applied to the associated breaker, which was the power source for the project.