-

What happened?

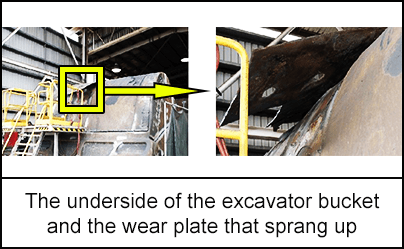

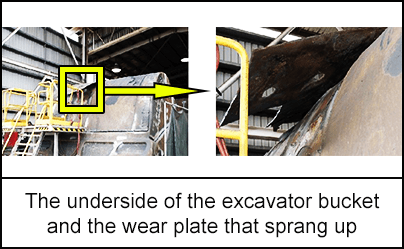

A coal mine worker was removing the wear plate from the bottom of a large excavator bucket.

The worker was using an arc gouging process to remove the plate, cutting it into smaller pieces.

The stored energy in the plate resulted in an uncontrolled elastic spring-back of the plate.

When the plate sprang upwards it struck the worker and caused fatal injuries.

-

Why did it happen?

The excavator bucket had been damaged, and had a dent where the wear plate met the bucket. This caused stress on the wear plate and a storage of spring-back energy.

The wear plate was not installed as per manufacturer’s instructions (which were designed for smaller plates), and most of the vertical welds on the plate had cracked. This meant the wear plate sprung back quickly.

Dirt had entered the space between the structural plate and wear plate because of the weld cracks. This increased deformation and the stress on the plate.

Other factors that can cause elastic spring-back in plates: misshapen plates, welding, wear and tear, poisson expansion (when the plate is dented during operations it expands and adds tension), and corrosion.

-

What did they learn?

All tasks should be risk assessed for spring-back potential (including greater precautions for larger wear plates).

Recommend that several smaller plates are used rather than one large plate as this reduces the risks during removal.

Conduct non-destructive testing to identify the condition of the bucket.

Review all work instructions and safe work procedures.

Ensure that permit systems include controls for stored energy hazards and the ‘line of fire’ is identified.

All workers should be competent to carry out maintenance and repairs, and aware of the risks associated with the work.

Consult the manufacturer about any alterations to the design of the plant and recommended maintenance procedures.

-

Ask yourself or your crew

What do you know about the dangers of stored energy?

Have you ever experienced ‘spring-back’ yourself?

How could something like this happen here?

What changes can we make to the way we carry out this task, or to the design of the bucket, to eliminate this risk?

Add to homescreen

Content name

Select existing category:

Content name

New collection

Edit collection

What happened?

A coal mine worker was removing the wear plate from the bottom of a large excavator bucket.

The worker was using an arc gouging process to remove the plate, cutting it into smaller pieces.

The stored energy in the plate resulted in an uncontrolled elastic spring-back of the plate.

When the plate sprang upwards it struck the worker and caused fatal injuries.

Why did it happen?

The excavator bucket had been damaged, and had a dent where the wear plate met the bucket. This caused stress on the wear plate and a storage of spring-back energy.

The wear plate was not installed as per manufacturer’s instructions (which were designed for smaller plates), and most of the vertical welds on the plate had cracked. This meant the wear plate sprung back quickly.

Dirt had entered the space between the structural plate and wear plate because of the weld cracks. This increased deformation and the stress on the plate.

Other factors that can cause elastic spring-back in plates: misshapen plates, welding, wear and tear, poisson expansion (when the plate is dented during operations it expands and adds tension), and corrosion.

What did they learn?

All tasks should be risk assessed for spring-back potential (including greater precautions for larger wear plates).

Recommend that several smaller plates are used rather than one large plate as this reduces the risks during removal.

Conduct non-destructive testing to identify the condition of the bucket.

Review all work instructions and safe work procedures.

Ensure that permit systems include controls for stored energy hazards and the ‘line of fire’ is identified.

All workers should be competent to carry out maintenance and repairs, and aware of the risks associated with the work.

Consult the manufacturer about any alterations to the design of the plant and recommended maintenance procedures.

Ask yourself or your crew

What do you know about the dangers of stored energy?

Have you ever experienced ‘spring-back’ yourself?

How could something like this happen here?

What changes can we make to the way we carry out this task, or to the design of the bucket, to eliminate this risk?

A coal mine worker received fatal injuries while removing a large wear plate from the bottom of a large excavator bucket.