-

What happened?

During the start-up process a crane slewed 2m (6.5ft) to the right without positive clearance.

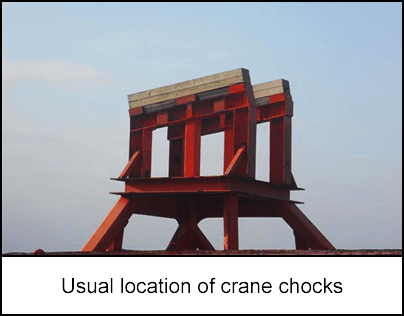

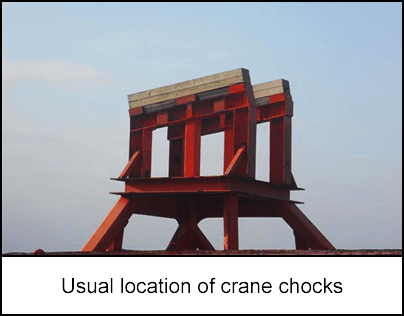

This caused the chocks to be dislodged from the rest.

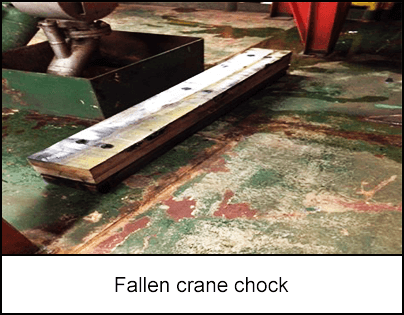

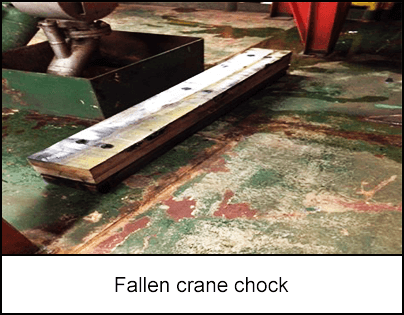

One chock remained on the rest, whilst the other fell 8m (26ft) below.

The fallen chock weighed 80kg (176lbs) and was L1.7m x W20 x D25 cm (L6ft x W8 x 10in).

The job was immediately stopped. Luckily no one was injured, but the incident was considered a fatality on the DROPS matrix.

-

Why did it happen?

Operator did not have positive clearance before slewing.

No secondary retention or robust securing to hold the chocks in place.

Risk was overlooked during DROPS survey, nor was it mentioned in any specific guidance.

- Chocks were not considered a DROPS risk as they can appear to be fixed when hand-checked (due to their weight).

Procedures and lifting plans did not state specific requirements for general crane operations.

-

What did they learn?

Verify and modify chock rests to prevent free falling. Consider the following scenarios:

- Impact with headache ball (weighed ball attached to lifting hook).

- Impact with suspended container.

- Wood deterioration due to weather exposure.

Revise and update procedures, risk assessments and lifting plans to include chock verification and robust securing.

Check crane rests and include in DROPS surveys.

-

Ask yourself or your crew

Think of a time when you or your colleagues proceeded with crane start-up without clearance. Why was that?

How can you check if the crane chocks are secured?

- What should you use to ‘robustly’ secure them?

What safe working procedures do you follow for crane use?

What other hazards should you be aware of when using cranes?

Add to homescreen

Content name

Select existing category:

Content name

New collection

Edit collection

What happened?

During the start-up process a crane slewed 2m (6.5ft) to the right without positive clearance.

This caused the chocks to be dislodged from the rest.

One chock remained on the rest, whilst the other fell 8m (26ft) below.

The fallen chock weighed 80kg (176lbs) and was L1.7m x W20 x D25 cm (L6ft x W8 x 10in).

The job was immediately stopped. Luckily no one was injured, but the incident was considered a fatality on the DROPS matrix.

Why did it happen?

Operator did not have positive clearance before slewing.

No secondary retention or robust securing to hold the chocks in place.

Risk was overlooked during DROPS survey, nor was it mentioned in any specific guidance.

- Chocks were not considered a DROPS risk as they can appear to be fixed when hand-checked (due to their weight).

Procedures and lifting plans did not state specific requirements for general crane operations.

What did they learn?

Verify and modify chock rests to prevent free falling. Consider the following scenarios:

- Impact with headache ball (weighed ball attached to lifting hook).

- Impact with suspended container.

- Wood deterioration due to weather exposure.

Revise and update procedures, risk assessments and lifting plans to include chock verification and robust securing.

Check crane rests and include in DROPS surveys.

Ask yourself or your crew

Think of a time when you or your colleagues proceeded with crane start-up without clearance. Why was that?

How can you check if the crane chocks are secured?

- What should you use to ‘robustly’ secure them?

What safe working procedures do you follow for crane use?

What other hazards should you be aware of when using cranes?

During the start-up process, a crane slewed to the right without positive clearance causing the chocks to be dislodged. One chalk fell 8m (26ft) to the ground.