-

What happened?

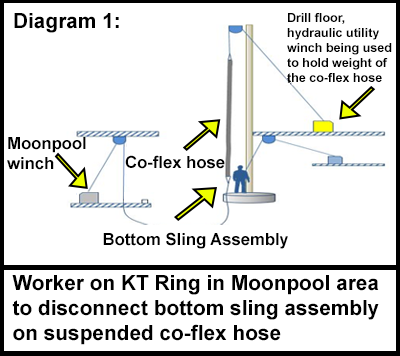

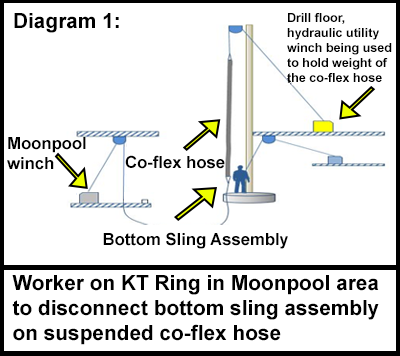

During a derigging operation, crew were lifting a co-flex hose from the moonpool area to the rig floor.

A worker was on the KT (tension) ring, trying to remove a lower sling assembly attached to the co-flex hose, left over from a previous task.

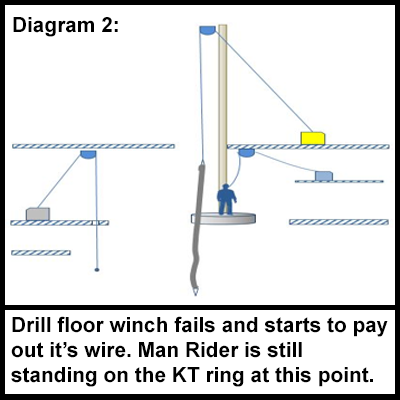

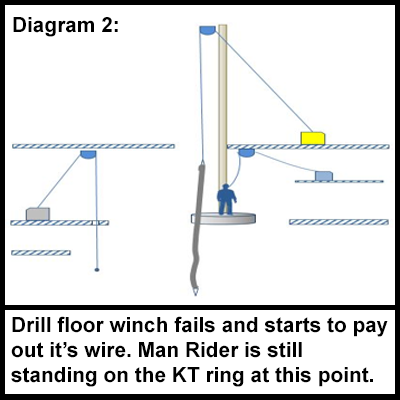

The winch had been holding the weight of the hose for 5 minutes when it suddenly began to pay-out.

The drill floor winch operator tried to activate the emergency stop, to no effect.

The co-flex hose descended uncontrollably, only stopping when it reached the 'dead end' termination, narrowly missing the worker on the KT ring.

-

Why did it happen?

After the winch was installed offshore, a hydraulic flow valve (that controls effective operation of the brake system) had been incorrectly adjusted.

The hydraulic utility winch's brakes were not tested independently of the hydraulic system, hiding potential defects.

Manufacturer's operating procedures for brake testing had been revised, but not communicated to the drilling contractor.

When planning the task, the hazards of 'man riding’ were not considered.

-

What did they learn?

Eliminate the hazard: is there a safer way to complete the job without working at heights, using a ‘man riding’ belt or working over water?

Consider the consequences of a failure (e.g. emergency brake failure). Identify and discuss the safeguards that minimise the consequences and keep you safe.

Ensure maintenance and inspection programmes are in place - especially those focused on barriers and safeguards.

-

Ask yourself or your crew

What other actions could have been taken?

How can something like this happen here?

What are the alternatives to working at height/over water?

How do we know brakes, and other safeguards, are working?

What is your role in ensuring the maintenance and inspection of barriers and safeguards?

Add to homescreen

Content name

Select existing category:

Content name

New collection

Edit collection

What happened?

During a derigging operation, crew were lifting a co-flex hose from the moonpool area to the rig floor.

A worker was on the KT (tension) ring, trying to remove a lower sling assembly attached to the co-flex hose, left over from a previous task.

The winch had been holding the weight of the hose for 5 minutes when it suddenly began to pay-out.

The drill floor winch operator tried to activate the emergency stop, to no effect.

The co-flex hose descended uncontrollably, only stopping when it reached the 'dead end' termination, narrowly missing the worker on the KT ring.

Why did it happen?

After the winch was installed offshore, a hydraulic flow valve (that controls effective operation of the brake system) had been incorrectly adjusted.

The hydraulic utility winch's brakes were not tested independently of the hydraulic system, hiding potential defects.

Manufacturer's operating procedures for brake testing had been revised, but not communicated to the drilling contractor.

When planning the task, the hazards of 'man riding’ were not considered.

What did they learn?

Eliminate the hazard: is there a safer way to complete the job without working at heights, using a ‘man riding’ belt or working over water?

Consider the consequences of a failure (e.g. emergency brake failure). Identify and discuss the safeguards that minimise the consequences and keep you safe.

Ensure maintenance and inspection programmes are in place - especially those focused on barriers and safeguards.

Ask yourself or your crew

What other actions could have been taken?

How can something like this happen here?

What are the alternatives to working at height/over water?

How do we know brakes, and other safeguards, are working?

What is your role in ensuring the maintenance and inspection of barriers and safeguards?

During a derigging operation, crew were lifting a co-flex hose from the moonpool area to the rig floor. The winch that has been holding the hose weight started to pay-out, resulting in the uncontrollable descent of the co-flex hose, narrowingly missing a worker positioned on the KT ring.