-

What happened?

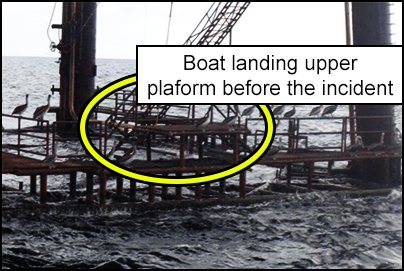

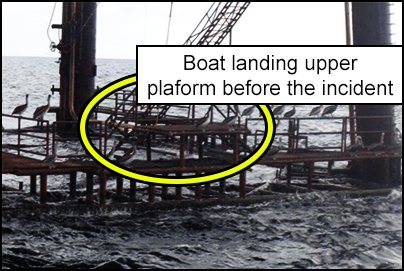

The marine supply vessel (MSV) arrived at an inactive platform to conduct a weekly inspection of it.

A worker used a swing rope to get to the boat landing and turned to go down the stairs.

As the worker turned, the landing broke free from the structure and the worker was thrown over a handrail.

Both the worker and the landing fell into the water.

The worker surfaced and held onto a support beam on the platform structure until he was rescued and transported to shore for medical treatment.

The worker suffered a broken leg and cuts to his other leg and knee.

-

Why did it happen?

The assessments of the inactive platform were only meant to be visual – no repairs were identified as necessary for a boat landing.

There was a lack of knowledge of the design/construction of the boat landing structure and how it would be affected by contact (e.g. if the vehicle hit the landing).

The platform operator had modified and raised the landing. The MSV made contact with this upper modified landing which did not absorb controlled impact energy.

-

What did they learn?

Confirm the boat landing’s structural system is designed to absorb energy based on the size of the vessel.

Ensure that integrity inspections and maintenance are carried out on boat landing areas before use.

Confirm that correct procedures for boat landings are in place and regularly assessed.

-

Ask yourself or your crew

How could something like this happen here?

What measures do we have in place to prevent it?

How do we know that a boat landing is safe to use?

What is the process for rescuing someone who falls into the water?

Add to homescreen

Content name

Select existing category:

Content name

New collection

Edit collection

What happened?

The marine supply vessel (MSV) arrived at an inactive platform to conduct a weekly inspection of it.

A worker used a swing rope to get to the boat landing and turned to go down the stairs.

As the worker turned, the landing broke free from the structure and the worker was thrown over a handrail.

Both the worker and the landing fell into the water.

The worker surfaced and held onto a support beam on the platform structure until he was rescued and transported to shore for medical treatment.

The worker suffered a broken leg and cuts to his other leg and knee.

Why did it happen?

The assessments of the inactive platform were only meant to be visual – no repairs were identified as necessary for a boat landing.

There was a lack of knowledge of the design/construction of the boat landing structure and how it would be affected by contact (e.g. if the vehicle hit the landing).

The platform operator had modified and raised the landing. The MSV made contact with this upper modified landing which did not absorb controlled impact energy.

What did they learn?

Confirm the boat landing’s structural system is designed to absorb energy based on the size of the vessel.

Ensure that integrity inspections and maintenance are carried out on boat landing areas before use.

Confirm that correct procedures for boat landings are in place and regularly assessed.

Ask yourself or your crew

How could something like this happen here?

What measures do we have in place to prevent it?

How do we know that a boat landing is safe to use?

What is the process for rescuing someone who falls into the water?

A worker was transferring from a marine supply vessel to a boat landing. When the worker stood on the landing, it broke and the worker fell into the water.