-

What happened?

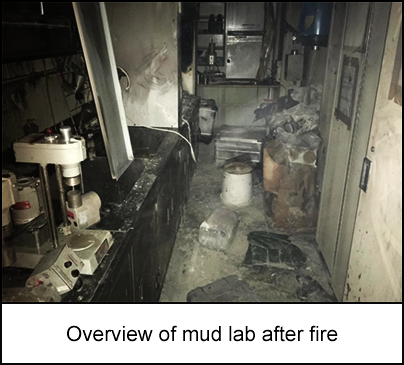

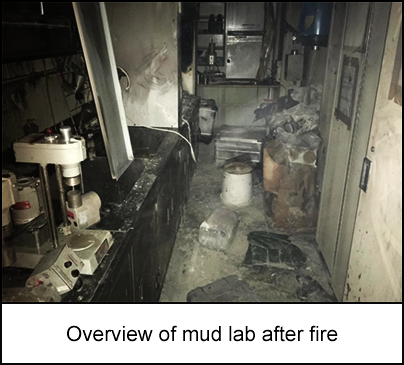

A retort was being used for drill mud testing (monitoring the quantities of water, oil and solids in drilling fluid) on an offshore rig.

The retort was located in a fume cabinet of a mud laboratory and powered by an extension cord with a power strip.

A fire ignited in the fume cabinet. The smoke alarm was activated.

Presence of fire was confirmed, personnel were removed from the scene and a general alarm was raised.

The fire team arrived shortly after the alarm was raised and quickly extinguished the fire.

The laboratory was partially destroyed. No workers were injured.

-

Why did it happen?

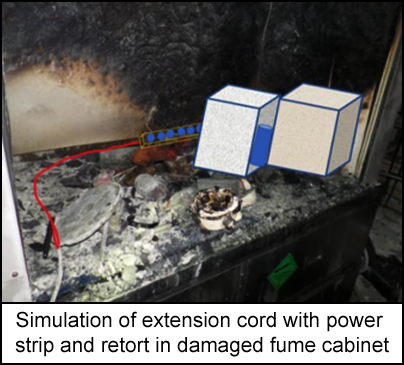

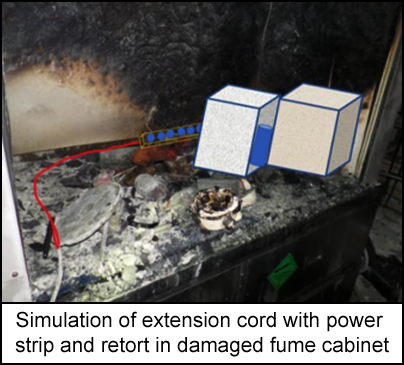

The probable cause of the fire was arcing in the extension cord with the power strip.

Arcing was likely the result of insulation failure.

- The 3m cord’s insulation was below standard – at the cross-section area was 1mm2 but should have been 1.5mm2 copper.

The heating element in the retort had no override function to prevent overheating if the thermostat failed.

Inadequate design of the fume cabinet:

- No internal power point, which required the use of the extension cord.

- Flammable cladding on the walls – not stainless steel as per design drawings.

Flammable chemicals were stored in the cabinet, which increased the scale of the fire.

-

What did they learn?

Ensure that fume cabinets and retorts in mud laboratories meet design specification and are maintained correctly.

Only use extension cords that are strong enough to avoid high temperature arcing. Include cords in the inspection programme.

Confirm that portable electrical equipment is checked for damage before being used.

Conduct regular inspections of the mud laboratory to confirm:

- correct storage of hazardous materials.

- vent hood is operated as per requirements.

-

Ask yourself or your crew

Have you ever experienced a fire in your workplace?

- What caused it?

- Could it have been prevented?

How do you know that all the equipment you are using is regularly inspected and within specifications (e.g. portable electrical equipment)?

How are the hazardous materials stored in your mud laboratory? Can we make it safer?

Add to homescreen

Content name

Select existing category:

Content name

New collection

Edit collection

What happened?

A retort was being used for drill mud testing (monitoring the quantities of water, oil and solids in drilling fluid) on an offshore rig.

The retort was located in a fume cabinet of a mud laboratory and powered by an extension cord with a power strip.

A fire ignited in the fume cabinet. The smoke alarm was activated.

Presence of fire was confirmed, personnel were removed from the scene and a general alarm was raised.

The fire team arrived shortly after the alarm was raised and quickly extinguished the fire.

The laboratory was partially destroyed. No workers were injured.

Why did it happen?

The probable cause of the fire was arcing in the extension cord with the power strip.

Arcing was likely the result of insulation failure.

- The 3m cord’s insulation was below standard – at the cross-section area was 1mm2 but should have been 1.5mm2 copper.

The heating element in the retort had no override function to prevent overheating if the thermostat failed.

Inadequate design of the fume cabinet:

- No internal power point, which required the use of the extension cord.

- Flammable cladding on the walls – not stainless steel as per design drawings.

Flammable chemicals were stored in the cabinet, which increased the scale of the fire.

What did they learn?

Ensure that fume cabinets and retorts in mud laboratories meet design specification and are maintained correctly.

Only use extension cords that are strong enough to avoid high temperature arcing. Include cords in the inspection programme.

Confirm that portable electrical equipment is checked for damage before being used.

Conduct regular inspections of the mud laboratory to confirm:

- correct storage of hazardous materials.

- vent hood is operated as per requirements.

Ask yourself or your crew

Have you ever experienced a fire in your workplace?

- What caused it?

- Could it have been prevented?

How do you know that all the equipment you are using is regularly inspected and within specifications (e.g. portable electrical equipment)?

How are the hazardous materials stored in your mud laboratory? Can we make it safer?

A fire occurred in mud laboratory on an offshore drilling rig. The fire began in the fume cabinet portion of the mud lab where the retort was placed. The laboratory was partially destroyed. No workers were injured.