-

What happened?

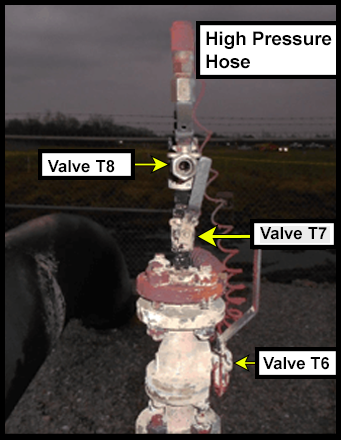

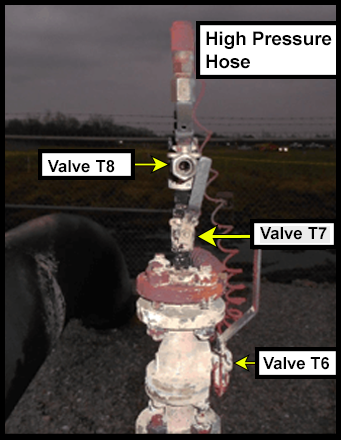

A work crew was launching a cleaning pig to the receiver trap.

While venting nitrogen from the receiver trap, a fire started.

The incident resulted in a fatality and multiple injuries.

-

Why did it happen?

They did not isolate the pipeline from the receiver trap.

This allowed product from the pipeline to escape to atmosphere during venting.

When it reached an ignition source, the fire started.

-

What did they learn?

Venting and purging activities should include written and detailed steps for valve line-up sequence for each part of the process.

Before venting, lock out tag out (LOTO) procedure (equipment specific) must be applied to all energy sources.

Venting of hydrocarbons and inert gases (nitrogen) should only be done to a safe location, with back-flow protection devices in place (i.e. check valves or isolation valves).

Only qualified/trained individuals should operate valves that vent to an uncontrolled system.

-

Ask yourself or your crew

What is your opinion of our critical procedures for energy isolation when pigging?

Before venting, how do you check if lock out tag out procedure has been applied to all energy sources?

How do you ensure that every step in a critical procedure is being followed?

What other actions could have been taken to prevent this incident?

If an event occurred, do you feel you would be blamed for not following a procedure even if the procedure was incorrect/out-of-date?

Add to homescreen

Content name

Select existing category:

Content name

New collection

Edit collection

What happened?

A work crew was launching a cleaning pig to the receiver trap.

While venting nitrogen from the receiver trap, a fire started.

The incident resulted in a fatality and multiple injuries.

Why did it happen?

They did not isolate the pipeline from the receiver trap.

This allowed product from the pipeline to escape to atmosphere during venting.

When it reached an ignition source, the fire started.

What did they learn?

Venting and purging activities should include written and detailed steps for valve line-up sequence for each part of the process.

Before venting, lock out tag out (LOTO) procedure (equipment specific) must be applied to all energy sources.

Venting of hydrocarbons and inert gases (nitrogen) should only be done to a safe location, with back-flow protection devices in place (i.e. check valves or isolation valves).

Only qualified/trained individuals should operate valves that vent to an uncontrolled system.

Ask yourself or your crew

What is your opinion of our critical procedures for energy isolation when pigging?

Before venting, how do you check if lock out tag out procedure has been applied to all energy sources?

How do you ensure that every step in a critical procedure is being followed?

What other actions could have been taken to prevent this incident?

If an event occurred, do you feel you would be blamed for not following a procedure even if the procedure was incorrect/out-of-date?

During a pigging operation, nitrogen vented in the atmosphere. A fire started, which resulted in 1 fatality and multiple injuries to crew members.