-

What happened?

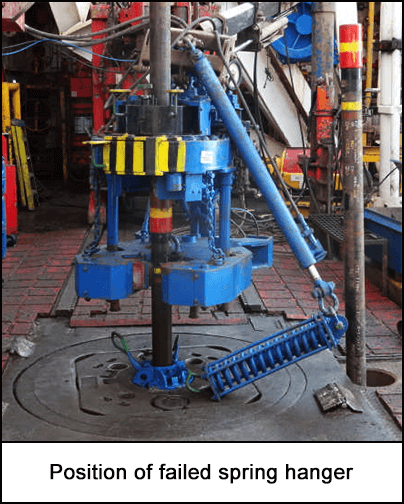

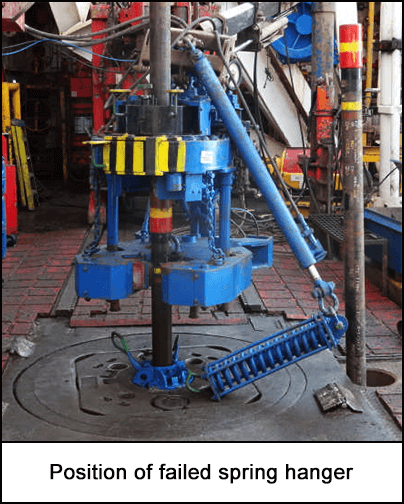

A work crew were making up a tubing joint.

A worker walked it in using a chain tong for 2 turns, then the tong was used to rotate the joint 5 more times with the back up released.

The back up was engaged and the tong operator was about to make the connection to the required torque when the spring hanger parted.

Part of the spring hanger (50kg / 110lb) and the lift cylinder (50kg /110lb) fell 4 metres (13 feet) to the drill floor while the inner rod recoiled up the derrick and came to rest at the sheave located just below the crown.

The tugger line from the reel side of the sheave coiled down to the drill floor.

-

Why did it happen?

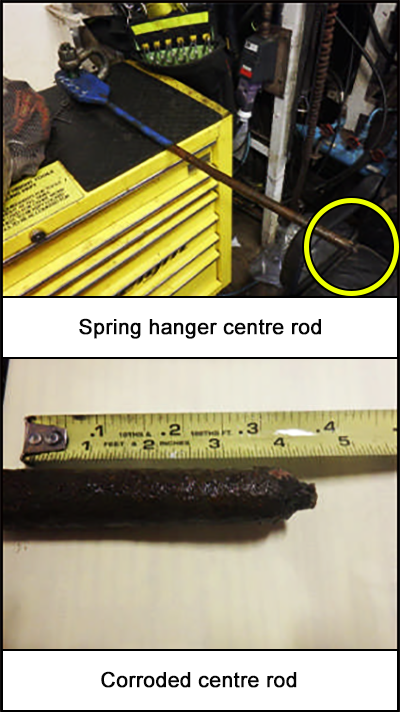

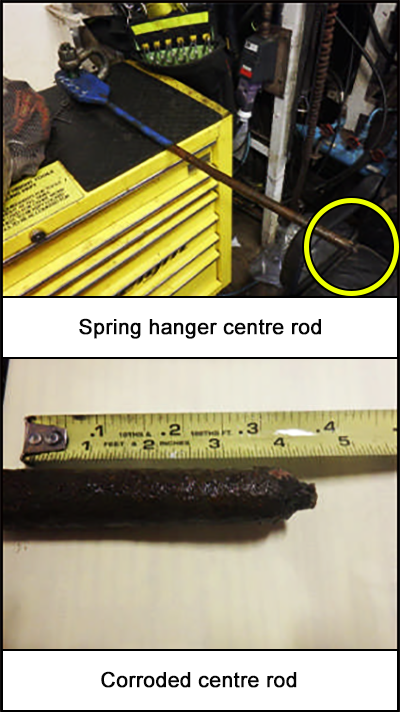

The failure was caused by severe corrosion of the spring hanger centre rod.

-

What did they learn?

Take all spring hangers out of service pending a review of their individual inspection/testing history.

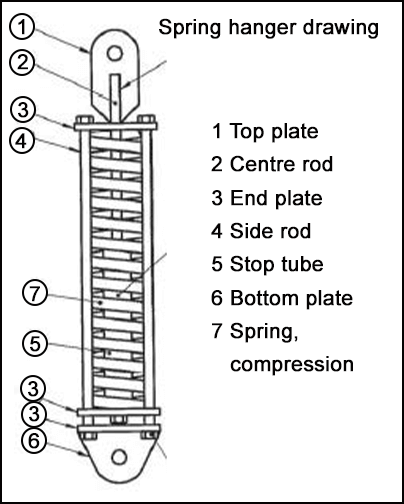

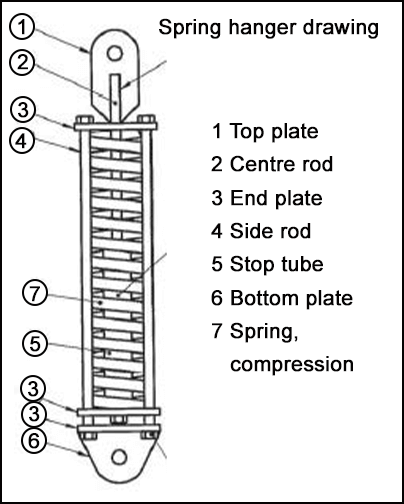

Ensure that a secondary retention sling is used between the top and bottom plates of the spring hanger.

Inspect and strip down all spring hangers (check condition of centre and outer rods, replacing stop tube).

Ensure spring hanger is load tested and inspected in line with procedure.

Review current spring hanger design and propose any modifications to allow easy access for servicing and inspection.

Carry out a risk assessment of the operation, taking into account snagging and other identified hazards.

Review lifesaving rules on dropped objects.

-

Ask yourself or your crew

Do you use spring hangers in your equipment? How often are they serviced?

What extra safety precautions can you take in your tasks to ensure that hazards are reduced?

Is there any equipment that you could use that would work better/be safer than what is in service?

What risk assessments do you carry out before starting your work?

Add to homescreen

Content name

Select existing category:

Content name

New collection

Edit collection

What happened?

A work crew were making up a tubing joint.

A worker walked it in using a chain tong for 2 turns, then the tong was used to rotate the joint 5 more times with the back up released.

The back up was engaged and the tong operator was about to make the connection to the required torque when the spring hanger parted.

Part of the spring hanger (50kg / 110lb) and the lift cylinder (50kg /110lb) fell 4 metres (13 feet) to the drill floor while the inner rod recoiled up the derrick and came to rest at the sheave located just below the crown.

The tugger line from the reel side of the sheave coiled down to the drill floor.

Why did it happen?

The failure was caused by severe corrosion of the spring hanger centre rod.

What did they learn?

Take all spring hangers out of service pending a review of their individual inspection/testing history.

Ensure that a secondary retention sling is used between the top and bottom plates of the spring hanger.

Inspect and strip down all spring hangers (check condition of centre and outer rods, replacing stop tube).

Ensure spring hanger is load tested and inspected in line with procedure.

Review current spring hanger design and propose any modifications to allow easy access for servicing and inspection.

Carry out a risk assessment of the operation, taking into account snagging and other identified hazards.

Review lifesaving rules on dropped objects.

Ask yourself or your crew

Do you use spring hangers in your equipment? How often are they serviced?

What extra safety precautions can you take in your tasks to ensure that hazards are reduced?

Is there any equipment that you could use that would work better/be safer than what is in service?

What risk assessments do you carry out before starting your work?

A crew were making up a tubing joint. The tong operator was about to make the connection to the required torque when the spring hanger parted – a piece of the spring hanger and the lift cylinder fell 4 metres (13 feet).