-

What happened?

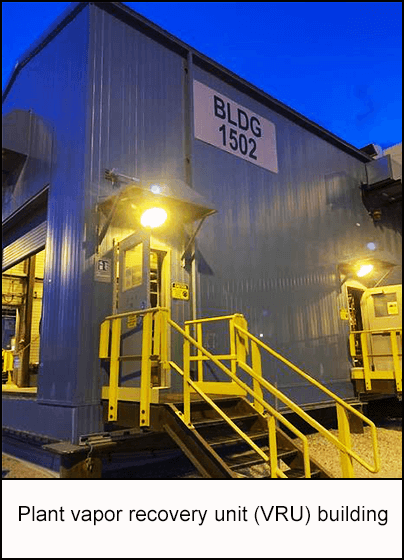

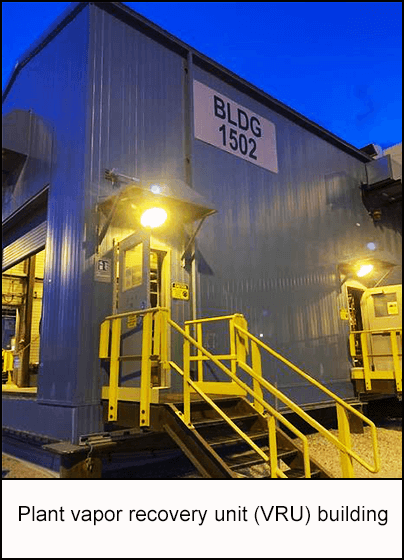

A vapour recovery unit (VRU) had been isolated for repairs.

During routine rounds, the bleed valve was verified, and operator confirmed there was no leakage.

Hours later, multiple lower explosive limit (LEL) alarms were activated in the VRU building, triggering a plant shutdown.

The operator opened the discharge drum flare valve in an attempt to reduce the pressure and limit any release.

When LEL dropped below 30%, the operator put on a self-contained breathing apparatus (SCBA).

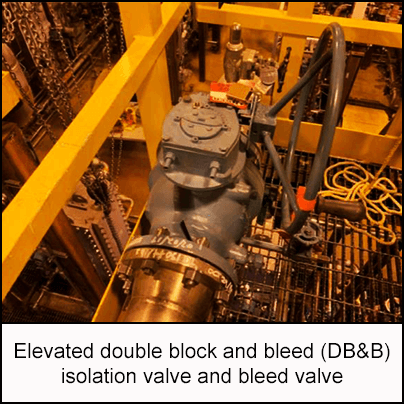

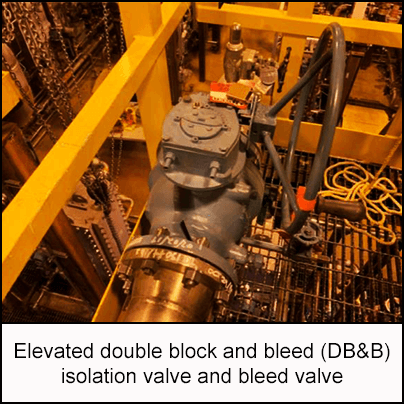

Solvent was released from the bleed on a ‘double block and bleed' (DB&B) valve.

Fortunately, the solvent did not ignite and there were no injuries.

The bleeding valve was closed and plugged to stop the release.

-

Why did it happen?

Downstream side of the DB&B failed – it required line pressure to energise the seal.

Incorrect practice previously performed and accepted on site - DB&B vent was left open and unattended, and left free to vent inside the building.

-

What did they learn?

Venting inside a building is more hazardous than venting outside. Ensure bleeds are venting to safe locations (e.g. outdoors) and the activity is properly monitored.

Verify that all DB&B valves are appropriate for service.

Ensure that workers know how to perform tasks correctly and are confident to challenge colleagues when working unsafely.

-

Ask yourself or your crew

What is our procedure for bleeding DB&B valves? What hazards should we look out for?

How do we check all valves are functioning as intended before starting work?

How can you challenge your colleague if you observe them working unsafely?

What is our emergency response procedure in the event of a chemical release?

Add to homescreen

Content name

Select existing category:

Content name

New collection

Edit collection

What happened?

A vapour recovery unit (VRU) had been isolated for repairs.

During routine rounds, the bleed valve was verified, and operator confirmed there was no leakage.

Hours later, multiple lower explosive limit (LEL) alarms were activated in the VRU building, triggering a plant shutdown.

The operator opened the discharge drum flare valve in an attempt to reduce the pressure and limit any release.

When LEL dropped below 30%, the operator put on a self-contained breathing apparatus (SCBA).

Solvent was released from the bleed on a ‘double block and bleed' (DB&B) valve.

Fortunately, the solvent did not ignite and there were no injuries.

The bleeding valve was closed and plugged to stop the release.

Why did it happen?

Downstream side of the DB&B failed – it required line pressure to energise the seal.

Incorrect practice previously performed and accepted on site - DB&B vent was left open and unattended, and left free to vent inside the building.

What did they learn?

Venting inside a building is more hazardous than venting outside. Ensure bleeds are venting to safe locations (e.g. outdoors) and the activity is properly monitored.

Verify that all DB&B valves are appropriate for service.

Ensure that workers know how to perform tasks correctly and are confident to challenge colleagues when working unsafely.

Ask yourself or your crew

What is our procedure for bleeding DB&B valves? What hazards should we look out for?

How do we check all valves are functioning as intended before starting work?

How can you challenge your colleague if you observe them working unsafely?

What is our emergency response procedure in the event of a chemical release?

A vapour recovery unit (VRU) was isolated in preparation for repairs when LEL alarms were activated. Solvent was released from the bleed on a ‘double block and bleed' (DB&B) valve. Fortunately, the solvent did not ignite and there were no injuries. The bleeding valve was closed and plugged to stop the release.