-

What happened?

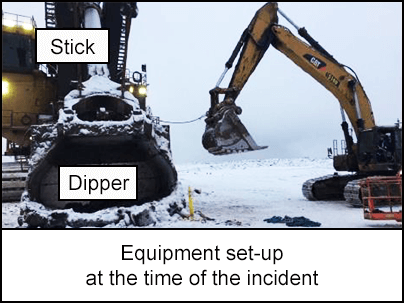

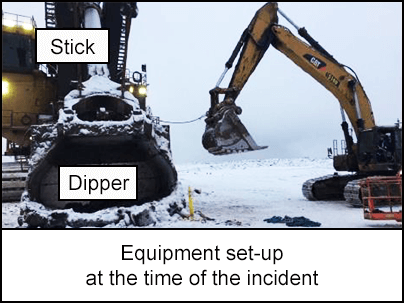

A work crew were pulling a pin from a shovel.

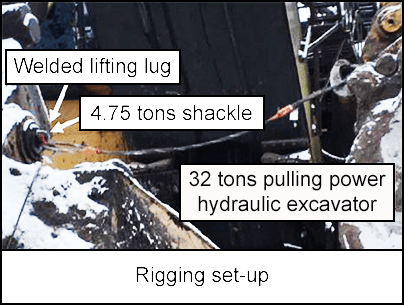

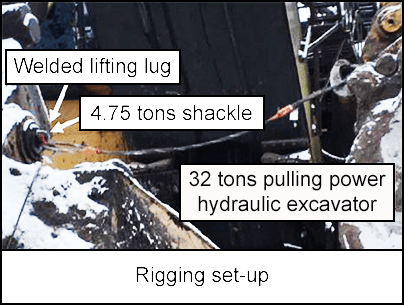

Rigging was connected at each end of the horizontal pulling. Rigging included a welded lifting lug to pin, connected wire rope with a shackle and a safety sling.

The shackle failed during the pulling. It flew back and shattered the excavator’s cab window.

The shackle landed at the operator’s feet, but there was no injury to the operator.

-

Why did it happen?

The crew did not verify the rigging load rating or follow revised procedure on using Kevlar slings.

A safety sling was used, but this was connected to the shackle.

The shackle was rated for 4.75 tons. The wire rope was rated at 15.5 ton and the excavator had a pulling power of 32 tons.

The procedures the crew were following did not have enough specific guidance on the equipment they needed to use.

The management/supervisors had several failings:

- They had not taken any actions/lessons learnt from a previous pin pulling incident.

- They had not confirmed the competency of the crew.

- The crews were not held accountable for following procedure.

- Supervisors were not held accountable for executing safety, security, health and environment (SSHE) responsibilities.

-

What did they learn?

Horizontal lifts should be treated with the same seriousness as vertical lifts.

Management is accountable for the quality and verification of all procedures.

Management should verify the competency of their workers.

-

Ask yourself or your crew

Have all the workers on your site been trained and verified as competent? How do you know?

Have your rigging plans been certified by a competent authority? How do you know?

How do you ensure that horizontal lifting/pulling activity treated with the same seriousness as vertical lifts in your worksite?

Is the potential to create stored energy being identified and mitigated so you can stay out of the line of fire? Where are the hazards and what controls have been put in place?

Add to homescreen

Content name

Select existing category:

Content name

New collection

Edit collection

What happened?

A work crew were pulling a pin from a shovel.

Rigging was connected at each end of the horizontal pulling. Rigging included a welded lifting lug to pin, connected wire rope with a shackle and a safety sling.

The shackle failed during the pulling. It flew back and shattered the excavator’s cab window.

The shackle landed at the operator’s feet, but there was no injury to the operator.

Why did it happen?

The crew did not verify the rigging load rating or follow revised procedure on using Kevlar slings.

A safety sling was used, but this was connected to the shackle.

The shackle was rated for 4.75 tons. The wire rope was rated at 15.5 ton and the excavator had a pulling power of 32 tons.

The procedures the crew were following did not have enough specific guidance on the equipment they needed to use.

The management/supervisors had several failings:

- They had not taken any actions/lessons learnt from a previous pin pulling incident.

- They had not confirmed the competency of the crew.

- The crews were not held accountable for following procedure.

- Supervisors were not held accountable for executing safety, security, health and environment (SSHE) responsibilities.

What did they learn?

Horizontal lifts should be treated with the same seriousness as vertical lifts.

Management is accountable for the quality and verification of all procedures.

Management should verify the competency of their workers.

Ask yourself or your crew

Have all the workers on your site been trained and verified as competent? How do you know?

Have your rigging plans been certified by a competent authority? How do you know?

How do you ensure that horizontal lifting/pulling activity treated with the same seriousness as vertical lifts in your worksite?

Is the potential to create stored energy being identified and mitigated so you can stay out of the line of fire? Where are the hazards and what controls have been put in place?

A work crew were pulling a pin from a shovel when the shackle failed and flew through the excavator’s cab window.