-

What happened?

A worker was preparing to use an oxy-acetylene torch on the back deck of a vessel.

The oxygen and acetylene cylinders were located on the quayside with the hoses rigged to the vessel.

On lighting the torch, a ‘pop’ sound was heard.

A small fire was observed from a rupture on the acetylene hose (just ahead of the flash-back arrestor).

-

Why did it happen?

Flash-back can occur when a torch is lit if a flammable mixture remains in the blowpipe or hoses.

Ignition can travel towards the cylinder, but is normally stopped by the flash-back arrestor (which prevents explosion or decomposition of the acetylene).

-

What did they learn?

Regularly check the condition of oxygen, acetylene hoses and flash-back arrestors. Ensure they are replaced as required.

Keep torches in good condition to avoid turbulent gas flow and reduce the risk of flash-back.

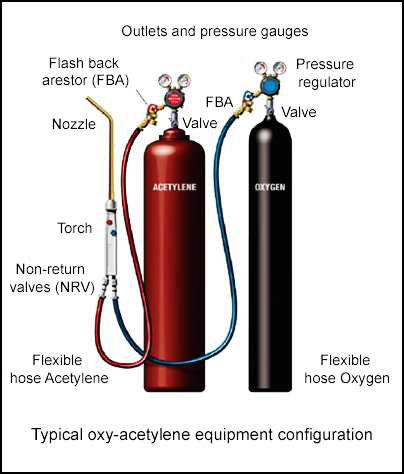

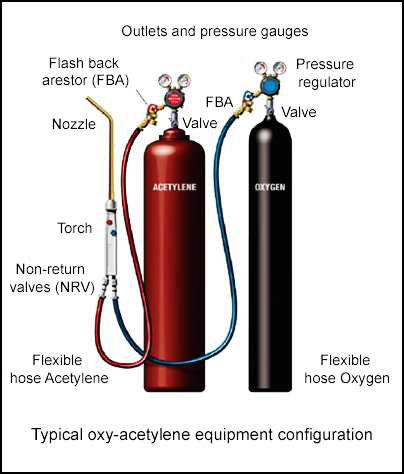

Ensure there is a non-return valve at the torch end of each hose and a pressure or temperature variation activated flash-back arrestor at the cylinder end.

Only use equipment designed for use with acetylene or oxygen.

Welding gas hoses should be correctly connected, and jubilee clips should never be used.

Ensure oxygen and acetylene hoses are separately purged to remove flammable mixtures before lighting the blowpipe.

Ensure all workers are aware and compliant with the above.

-

Ask yourself or your crew

Has anything like this ever happened to you or a colleague? How was it different?

What are the risks of using oxy-acetylene equipment? What can go wrong and how can we prevent it?

Is all the equipment you are using correct/fit for purpose? What should do if not?

What preventative maintenance and testing do you carry out on your equipment? What more can you do?

Add to homescreen

Content name

Select existing category:

Content name

New collection

Edit collection

What happened?

A worker was preparing to use an oxy-acetylene torch on the back deck of a vessel.

The oxygen and acetylene cylinders were located on the quayside with the hoses rigged to the vessel.

On lighting the torch, a ‘pop’ sound was heard.

A small fire was observed from a rupture on the acetylene hose (just ahead of the flash-back arrestor).

Why did it happen?

Flash-back can occur when a torch is lit if a flammable mixture remains in the blowpipe or hoses.

Ignition can travel towards the cylinder, but is normally stopped by the flash-back arrestor (which prevents explosion or decomposition of the acetylene).

What did they learn?

Regularly check the condition of oxygen, acetylene hoses and flash-back arrestors. Ensure they are replaced as required.

Keep torches in good condition to avoid turbulent gas flow and reduce the risk of flash-back.

Ensure there is a non-return valve at the torch end of each hose and a pressure or temperature variation activated flash-back arrestor at the cylinder end.

Only use equipment designed for use with acetylene or oxygen.

Welding gas hoses should be correctly connected, and jubilee clips should never be used.

Ensure oxygen and acetylene hoses are separately purged to remove flammable mixtures before lighting the blowpipe.

Ensure all workers are aware and compliant with the above.

Ask yourself or your crew

Has anything like this ever happened to you or a colleague? How was it different?

What are the risks of using oxy-acetylene equipment? What can go wrong and how can we prevent it?

Is all the equipment you are using correct/fit for purpose? What should do if not?

What preventative maintenance and testing do you carry out on your equipment? What more can you do?

A worker was preparing to use an oxy-acetylene torch. When the torch was lit, a ‘pop’ sound was heard, and a small fire was observed.