-

What happened?

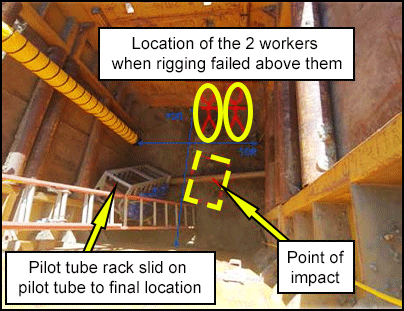

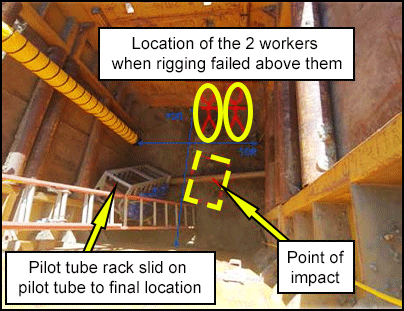

An excavator was being used to lift a pilot tube rack weighing 1.425kg (3.140) lbs from an excavation 1m² (10ft²).

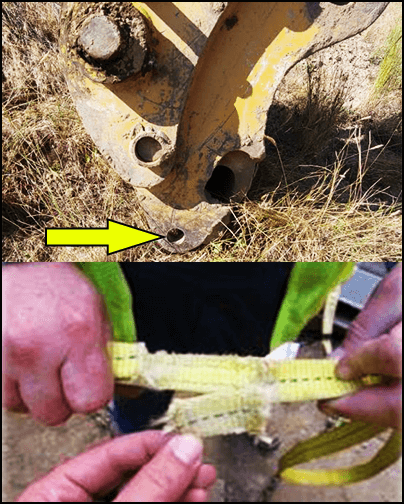

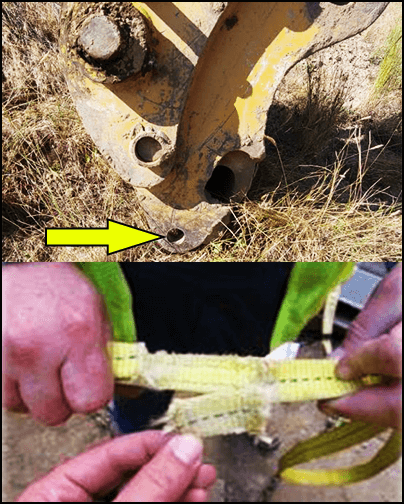

A synthetic sling was used through the eye on the excavator arm as workers could not find the right sized shackle.

The workers stayed in the excavation during the lift, moving to one corner to avoid being under the load.

The sling failed and the load fell 5m (16ft) back into the excavation, narrowly missing the workers by 0.6m (2ft).

-

Why did it happen?

The synthetic sling got damaged. It was ran through the eye of the excavator arm - without softeners or a rounded shackle to protect it from sharp edges.

The wrong length of sling was used for attaching the rack to the rigging (1.8m/6ft instead of 3m/10ft).

There was no guidance on using an excavator for lifting activity.

The crew did not have a dedicated rigger assigned. They failed to consider the danger (potential for horizontal deflection) if the rigging failed.

-

What did they learn?

Implement a procedure for lifting with excavators that meets lifting requirements.

Only certified riggers should be responsible for rigging to ensure appropriate equipment is used.

Establish appropriate exclusion zones for lifting and rigging activity.

-

Ask yourself or your crew

How can this happen here? What measures do we have in place to prevent a similar incident?

Have you been on a worksite where excavators have been used for lifting?

What are the hazards of using excavators for lifting and rigging activities?

What other hazards should you be aware of in your task?

Add to homescreen

Content name

Select existing category:

Content name

New collection

Edit collection

What happened?

An excavator was being used to lift a pilot tube rack weighing 1.425kg (3.140) lbs from an excavation 1m² (10ft²).

A synthetic sling was used through the eye on the excavator arm as workers could not find the right sized shackle.

The workers stayed in the excavation during the lift, moving to one corner to avoid being under the load.

The sling failed and the load fell 5m (16ft) back into the excavation, narrowly missing the workers by 0.6m (2ft).

Why did it happen?

The synthetic sling got damaged. It was ran through the eye of the excavator arm - without softeners or a rounded shackle to protect it from sharp edges.

The wrong length of sling was used for attaching the rack to the rigging (1.8m/6ft instead of 3m/10ft).

There was no guidance on using an excavator for lifting activity.

The crew did not have a dedicated rigger assigned. They failed to consider the danger (potential for horizontal deflection) if the rigging failed.

What did they learn?

Implement a procedure for lifting with excavators that meets lifting requirements.

Only certified riggers should be responsible for rigging to ensure appropriate equipment is used.

Establish appropriate exclusion zones for lifting and rigging activity.

Ask yourself or your crew

How can this happen here? What measures do we have in place to prevent a similar incident?

Have you been on a worksite where excavators have been used for lifting?

What are the hazards of using excavators for lifting and rigging activities?

What other hazards should you be aware of in your task?

An excavator was being used to lift a pilot tube rack from an excavation. The synthetic sling used failed, and the load fell back into the excavation, narrowly missing workers.