-

What happened?

Two workers entered a column to perform a welding task.

When one worker felt light headed, both exited the column.

It was later believed that oxygen levels had fallen below 19.5%.

The welder was discharged with no medical treatment needed, but could have been killed or severely disabled.

-

Why did it happen?

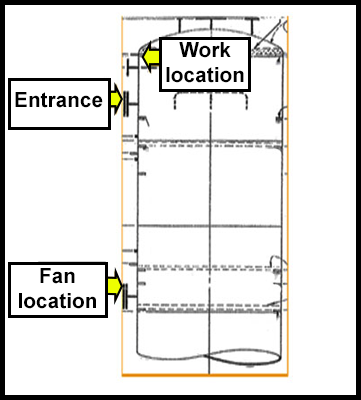

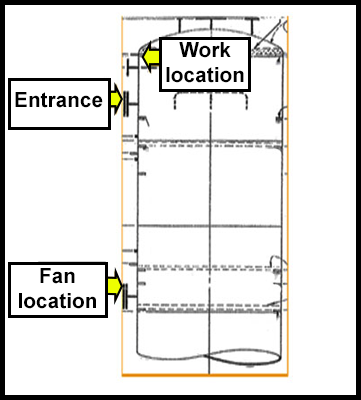

There was poor air flow inside the column, due to scaffolding and the column internals.

The atmosphere was being monitored at the point of entry only, not at the location of the job.

Workers were not wearing individual gas monitors.

-

What did they learn?

When working in confined spaces:

- The levels of oxygen and other gases must be constantly monitored.

- There must be sufficient air flow to the work area. Plan how to make this happen. Install ventilation at the work location.

- Workers must wear the right PPE (e.g. respirators, personal gas monitors).

-

Ask yourself or your crew

What other actions could have been taken?

How can something like this happen here?

Before entering the confined space, how do we know that:

- the levels of oxygen and other gases are in the permitted limits?

- there is adequate air flow?

- adequate protective equipment is worn?

Add to homescreen

If you want to add this app to home screen tap and then ‘Add to Home Screen’.

Content name

Select existing category:

Content name

New collection

Edit collection

What happened?

Two workers entered a column to perform a welding task.

When one worker felt light headed, both exited the column.

It was later believed that oxygen levels had fallen below 19.5%.

The welder was discharged with no medical treatment needed, but could have been killed or severely disabled.

Why did it happen?

There was poor air flow inside the column, due to scaffolding and the column internals.

The atmosphere was being monitored at the point of entry only, not at the location of the job.

Workers were not wearing individual gas monitors.

What did they learn?

When working in confined spaces:

- The levels of oxygen and other gases must be constantly monitored.

- There must be sufficient air flow to the work area. Plan how to make this happen. Install ventilation at the work location.

- Workers must wear the right PPE (e.g. respirators, personal gas monitors).

Ask yourself or your crew

What other actions could have been taken?

How can something like this happen here?

Before entering the confined space, how do we know that:

- the levels of oxygen and other gases are in the permitted limits?

- there is adequate air flow?

- adequate protective equipment is worn?

Published on 10/07/19

4253 Views

Two workers entered a column to perform a welding task. One felt light headed, so both exited the column. It was later believed that oxygen levels had fallen below 19.5%.