-

What happened?

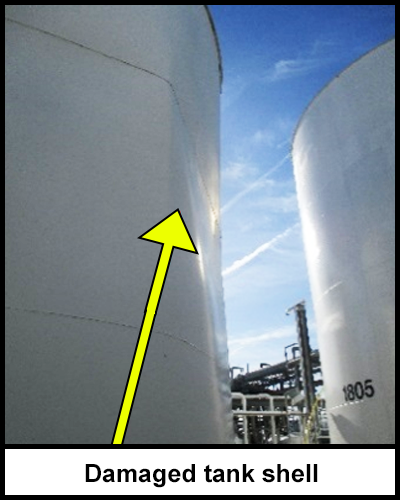

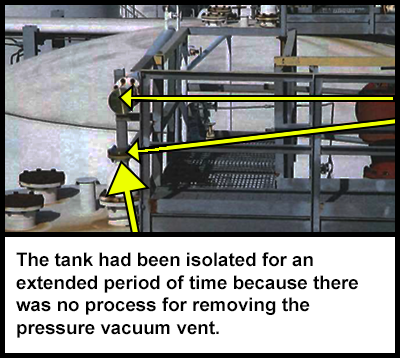

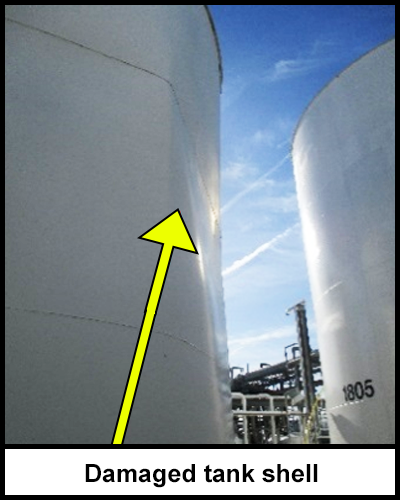

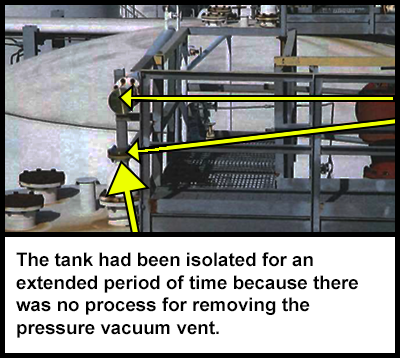

A 2100 barrel carbon steel above-ground storage tank was isolated for regulatory testing of the pressure vacuum vent.

Negative pressure in the tank was caused by rain accompanied by a 30 degrees drop in temperature.

The pressure was relieved through the tank roof piping, but the tank shell was damaged.

-

Why did it happen?

The drop in temperature caused condensation within the vapour space, reducing internal atmosphere from positive to negative.

The crew did not know that negative pressure could occur while the tank was isolated.

-

What did they learn?

Negative pressure can occur in an isolated tank.

External factors such as rain and drops in temperature can lead to negative pressure.

Limit the amount of time that the tank is isolated for.

Create a process for removing pressure relief equipment from process equipment.

-

Ask yourself or your crew

What actions could have been taken?

How could something like this happen here and how can we prevent it?

Do we take into consideration atmospheric conditions when we isolate tanks for testing? Why?

How can we improve our current practices to prevent negative pressures?

Add to homescreen

Content name

Select existing category:

Content name

New collection

Edit collection

What happened?

A 2100 barrel carbon steel above-ground storage tank was isolated for regulatory testing of the pressure vacuum vent.

Negative pressure in the tank was caused by rain accompanied by a 30 degrees drop in temperature.

The pressure was relieved through the tank roof piping, but the tank shell was damaged.

Why did it happen?

The drop in temperature caused condensation within the vapour space, reducing internal atmosphere from positive to negative.

The crew did not know that negative pressure could occur while the tank was isolated.

What did they learn?

Negative pressure can occur in an isolated tank.

External factors such as rain and drops in temperature can lead to negative pressure.

Limit the amount of time that the tank is isolated for.

Create a process for removing pressure relief equipment from process equipment.

Ask yourself or your crew

What actions could have been taken?

How could something like this happen here and how can we prevent it?

Do we take into consideration atmospheric conditions when we isolate tanks for testing? Why?

How can we improve our current practices to prevent negative pressures?

Negative pressure in a tank was caused by rain accompanied by a 30 degrees drop in temperature. The pressure was relieved through the tank roof piping, but the tank shell was damaged.