-

What happened?

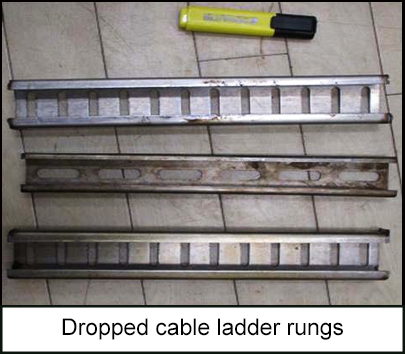

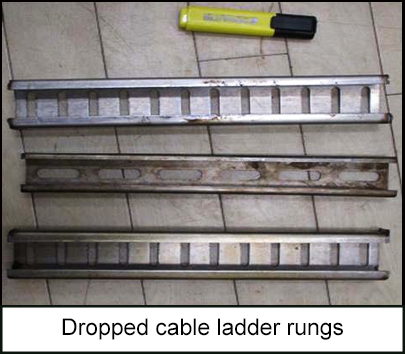

Following a period of high winds, a deck foreman observed three rungs dropped onto the skid deck.

The rungs came off a cable ladder rack located within the drilling derrick.

The heaviest rung weighed 0.45kg (1lb) and fell from a height of 48.4m (159 ft).

No one was injured, but the incident had potential to cause fatality.

A full sweep was conducted by rope access personnel to ensure there were no other areas of loose cable rack within the derrick that could pose a dropped object risk.

-

Why did it happen?

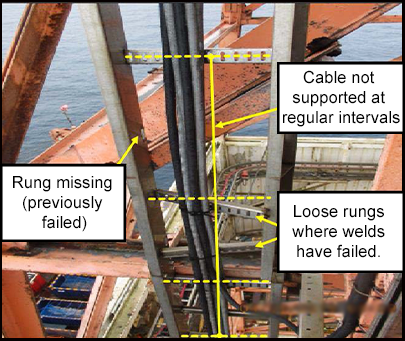

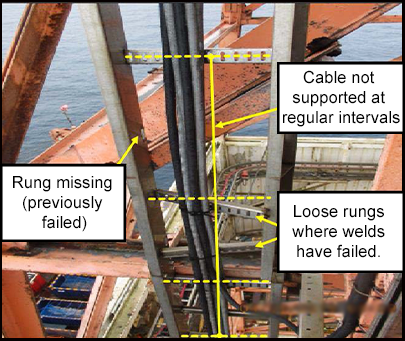

Inspection surveys failed to identify:

- fatigue caused by movement in exposed location. The prefabricated cable racks with welded rungs had been in place for more than 30 years.

- Cable fasteners used were of incorrect specification and at incorrect spacing.

The cables were not adequately secured to the ladder rack:

- plastic cable fasteners were used instead of the required metal cable fasteners.

- cables were not supported at regular intervals

- the bundle spanned multiple rungs, instead of the minimum of every second rung required for low voltage cable.

-

What did they learn?

Ensure equipment fatigue identification is included in the inspection surveys.

Conduct a sweep of the area to ensure there are no other loose parts that could pose a dropped object risk.

-

Ask yourself or your crew

Why do you think inspections failed to identify fatigue and incorrect practices (incorrect fasteners type and spacing)?

What should you do if you notice a loose cable rack or other equipment failures on site? Who do you need to report it to and what should they do about it?

What measures do we have in place to ensure thorough inspections that can identify equipment fatigue on site? How can we improve?

Add to homescreen

Content name

Select existing category:

Content name

New collection

Edit collection

What happened?

Following a period of high winds, a deck foreman observed three rungs dropped onto the skid deck.

The rungs came off a cable ladder rack located within the drilling derrick.

The heaviest rung weighed 0.45kg (1lb) and fell from a height of 48.4m (159 ft).

No one was injured, but the incident had potential to cause fatality.

A full sweep was conducted by rope access personnel to ensure there were no other areas of loose cable rack within the derrick that could pose a dropped object risk.

Why did it happen?

Inspection surveys failed to identify:

- fatigue caused by movement in exposed location. The prefabricated cable racks with welded rungs had been in place for more than 30 years.

- Cable fasteners used were of incorrect specification and at incorrect spacing.

The cables were not adequately secured to the ladder rack:

- plastic cable fasteners were used instead of the required metal cable fasteners.

- cables were not supported at regular intervals

- the bundle spanned multiple rungs, instead of the minimum of every second rung required for low voltage cable.

What did they learn?

Ensure equipment fatigue identification is included in the inspection surveys.

Conduct a sweep of the area to ensure there are no other loose parts that could pose a dropped object risk.

Ask yourself or your crew

Why do you think inspections failed to identify fatigue and incorrect practices (incorrect fasteners type and spacing)?

What should you do if you notice a loose cable rack or other equipment failures on site? Who do you need to report it to and what should they do about it?

What measures do we have in place to ensure thorough inspections that can identify equipment fatigue on site? How can we improve?

Three rungs from a cable ladder rack dropped onto a skid deck after a period of high winds. The heaviest weighed 0.45kg (1lb) and fell from a height of 48m (159 ft). No one was injured, but the incident had potential to cause fatality.