-

What happened?

An electrical operator was checking the electric line of boundary lighting.

The operator asked the supervisor to turn off the power supply in order to isolate the line.

The supervisor did not do a lock-out tag-out (LOTO) and turned off the wrong cut-out switch.

Operator then started the maintenance inspection where he removed the electrical tape (insulation) from the cable joint.

He suffered an electric shock to his hand.

-

Why did it happen?

Equipment was poorly organised: two cut-out switches were available on the electrical switchboard but not marked.

Personal protective equipment (PPE) was not used.

Lack of judgment and knowledge – poor evaluation of the risks by the inexperienced workers.

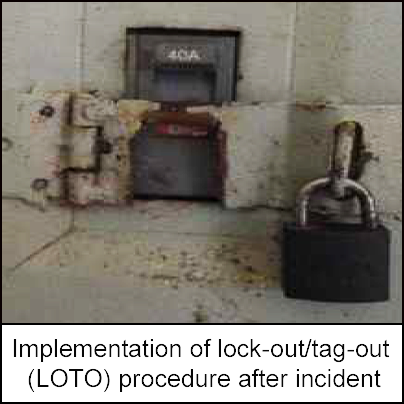

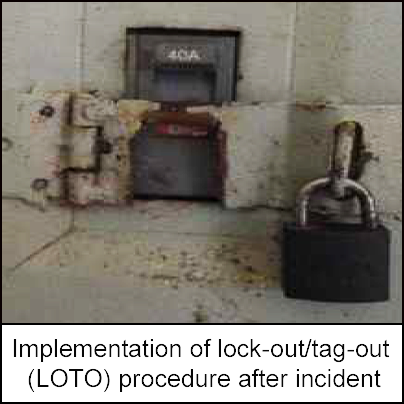

Only manual isolation was employed as the control measure. Absence of lock-out tag-out (LOTO) that could positively isolate this type of circuit breaker.

Absence of locking isolation and signage of ‘man working on equipment’ during maintenance.

-

What did they learn?

Before performing maintenance/inspection work, ensure the power and product supply has been switched off.

Review procedures and practices (work permits, prevention plans etc.) for jobs on energised systems.

- Focus on effective enforcement of established procedures – LOTO.

- Ensure LOTO is in place for electrical isolation.

Do not access installations or perform work without wearing general or task-specific PPE (e.g. rubber insulating gloves for electrical work).

Remind staff of required PPE (e.g. display PPE in relevant work zones).

Train site managers and contractors on all relevant procedures, minimum PPE and first aid.

Carry out work site safety training for staff and regular contractors.

-

Ask yourself of your crew

How can something like this happen here?

What is the risk of us isolating the wrong equipment? What can we do to mitigate the risk?

How do we know when electrical equipment has been isolated? What more can we do?

How can we ensure LOTO is used?

What PPE do we need to wear for today’s electrical task?

What else can we learn from this incident?

Add to homescreen

Content name

Select existing category:

Content name

New collection

Edit collection

What happened?

An electrical operator was checking the electric line of boundary lighting.

The operator asked the supervisor to turn off the power supply in order to isolate the line.

The supervisor did not do a lock-out tag-out (LOTO) and turned off the wrong cut-out switch.

Operator then started the maintenance inspection where he removed the electrical tape (insulation) from the cable joint.

He suffered an electric shock to his hand.

Why did it happen?

Equipment was poorly organised: two cut-out switches were available on the electrical switchboard but not marked.

Personal protective equipment (PPE) was not used.

Lack of judgment and knowledge – poor evaluation of the risks by the inexperienced workers.

Only manual isolation was employed as the control measure. Absence of lock-out tag-out (LOTO) that could positively isolate this type of circuit breaker.

Absence of locking isolation and signage of ‘man working on equipment’ during maintenance.

What did they learn?

Before performing maintenance/inspection work, ensure the power and product supply has been switched off.

Review procedures and practices (work permits, prevention plans etc.) for jobs on energised systems.

- Focus on effective enforcement of established procedures – LOTO.

- Ensure LOTO is in place for electrical isolation.

Do not access installations or perform work without wearing general or task-specific PPE (e.g. rubber insulating gloves for electrical work).

Remind staff of required PPE (e.g. display PPE in relevant work zones).

Train site managers and contractors on all relevant procedures, minimum PPE and first aid.

Carry out work site safety training for staff and regular contractors.

Ask yourself of your crew

How can something like this happen here?

What is the risk of us isolating the wrong equipment? What can we do to mitigate the risk?

How do we know when electrical equipment has been isolated? What more can we do?

How can we ensure LOTO is used?

What PPE do we need to wear for today’s electrical task?

What else can we learn from this incident?

During electrical maintenance, the supervisor isolated the wrong section, leading to electric shock of his colleague. Lock-out tag-out wasn’t used and the switches were poorly organised.