-

What happened?

Lifter borers are mobile cranes, used to install and remove power poles for the power supply industry.

The lifter borer involved in the incident was nearly 20 years old.

An attempt was made to use the lifter borer to pull a pole out of the ground.

The lifter borer’s boom broke off close to its pivot point.

The failed boom was supported by the pole grips holding the pole into the ground, however without this it would have dropped to the ground.

The operator’s seat is next to the boom – had the boom dropped the operator could have been seriously injured.

-

Why did it happen?

Lifter borers are often be used to pull poles out of the ground, but it is not generally recommended by manufacturers.

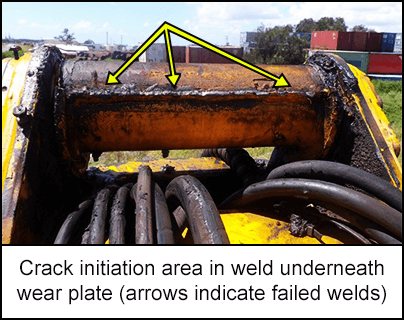

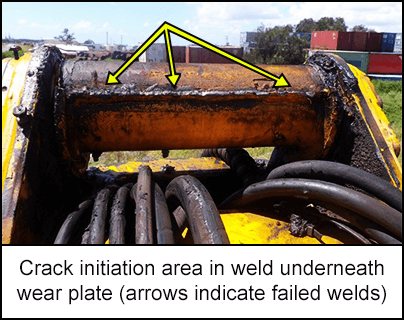

The age and condition of the lift borer – a large amount of grease and dirt around the failure area hid cracks in the welds.

General insufficient maintenance and inspection of the lifter borer.

-

What did they learn?

Always operate lift borers according to manufacturer’s instructions.

If a rated capacity limit system is provided, it should not be overridden whilst lifting a load.

It is not recommended that lifter borers be used to pull poles out of the ground. If they are, it should only be done in line with manufacturer’s instructions.

Lifter borers should be inspected prior to use and regularly maintained (the frequency will depend on its use and age).

In addition, a major inspection (stripping down the machine) should be carried out every 10 years.

All inspections should be carried out by competent personnel.

-

Ask yourself or your crew

How can something like this happen here?

Do we use lifter borers according to manufacturers’ guidelines?

If we use lifter borers for this activity, what could we do instead?

Do we have equipment where grease and dirt might hide bigger issues?

When was our equipment last inspected and maintained? How can you check?

Add to homescreen

Content name

Select existing category:

Content name

New collection

Edit collection

What happened?

Lifter borers are mobile cranes, used to install and remove power poles for the power supply industry.

The lifter borer involved in the incident was nearly 20 years old.

An attempt was made to use the lifter borer to pull a pole out of the ground.

The lifter borer’s boom broke off close to its pivot point.

The failed boom was supported by the pole grips holding the pole into the ground, however without this it would have dropped to the ground.

The operator’s seat is next to the boom – had the boom dropped the operator could have been seriously injured.

Why did it happen?

Lifter borers are often be used to pull poles out of the ground, but it is not generally recommended by manufacturers.

The age and condition of the lift borer – a large amount of grease and dirt around the failure area hid cracks in the welds.

General insufficient maintenance and inspection of the lifter borer.

What did they learn?

Always operate lift borers according to manufacturer’s instructions.

If a rated capacity limit system is provided, it should not be overridden whilst lifting a load.

It is not recommended that lifter borers be used to pull poles out of the ground. If they are, it should only be done in line with manufacturer’s instructions.

Lifter borers should be inspected prior to use and regularly maintained (the frequency will depend on its use and age).

In addition, a major inspection (stripping down the machine) should be carried out every 10 years.

All inspections should be carried out by competent personnel.

Ask yourself or your crew

How can something like this happen here?

Do we use lifter borers according to manufacturers’ guidelines?

If we use lifter borers for this activity, what could we do instead?

Do we have equipment where grease and dirt might hide bigger issues?

When was our equipment last inspected and maintained? How can you check?

A lift borer was being used to remove a pole out of the ground. The lift borer’s boom broke off near the pivot point and was only supported by pole grips holding the pole into the ground. Had the boom dropped the operator could have been seriously injured.