-

What happened?

Periodic routine maintenance was being carried out on a hydrogen sulphide (H2S) detection and alarm system situated in a loading rack.

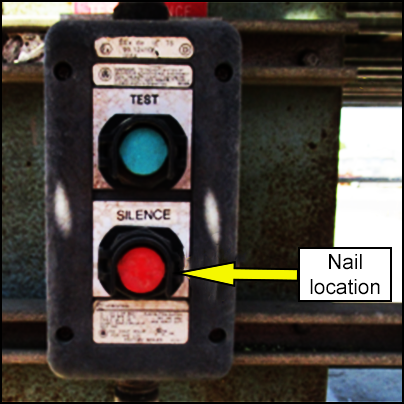

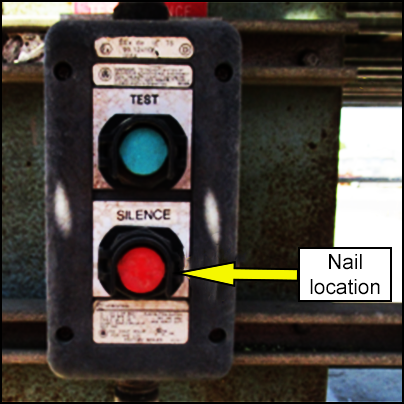

Workers discovered a nail was jammed into the silence button, keeping it permanently engaged and consequently disabling the audible alarm.

Although the audible alarm was silenced at the rack, the H2S alarm level was still detected by the distributed control system (DCS).

When the DCS detected low H2S levels (</10ppm), the main alarm horn was activated and reset repeatedly until the situation was investigated.

-

Why did it happen?

The alarm was triggered repeatedly at low levels of H2S (</ 10 ppm), which became a nuisance for the workers. An unknown person decided to permanently silence the alarm using a nail.

The design and location of the detection system allowed tampering with the silence button.

-

What did they learn?

If alarms activate at low levels, investigate to determine the cause.

Workers should be are aware of the alarm system and how to respond should it activate.

Consider changing the system design where alarms could be tampered with manually.

Implement additional checks in between periodic maintenance where required.

-

Ask yourself or your crew

Do we have any ‘nuisance alarms’ (that go off frequently or are too sensitive)? What could the consequences be of deactivating them? What can be done to improve their function?

What are the consequences of H2S exposure?

How should you respond to a toxic gas detection alarm?

What other toxic gases might you come across in your work area? How are they monitored?

Add to homescreen

Content name

Select existing category:

Content name

New collection

Edit collection

What happened?

Periodic routine maintenance was being carried out on a hydrogen sulphide (H2S) detection and alarm system situated in a loading rack.

Workers discovered a nail was jammed into the silence button, keeping it permanently engaged and consequently disabling the audible alarm.

Although the audible alarm was silenced at the rack, the H2S alarm level was still detected by the distributed control system (DCS).

When the DCS detected low H2S levels (</10ppm), the main alarm horn was activated and reset repeatedly until the situation was investigated.

Why did it happen?

The alarm was triggered repeatedly at low levels of H2S (</ 10 ppm), which became a nuisance for the workers. An unknown person decided to permanently silence the alarm using a nail.

The design and location of the detection system allowed tampering with the silence button.

What did they learn?

If alarms activate at low levels, investigate to determine the cause.

Workers should be are aware of the alarm system and how to respond should it activate.

Consider changing the system design where alarms could be tampered with manually.

Implement additional checks in between periodic maintenance where required.

Ask yourself or your crew

Do we have any ‘nuisance alarms’ (that go off frequently or are too sensitive)? What could the consequences be of deactivating them? What can be done to improve their function?

What are the consequences of H2S exposure?

How should you respond to a toxic gas detection alarm?

What other toxic gases might you come across in your work area? How are they monitored?

Periodic routine maintenance was being carried out on a hydrogen sulphide (H2S) detection and alarm system situated in a loading rack. Workers discovered a nail was jammed into the silence button, keeping it permanently engaged and consequently disabling the audible alarm.