-

What happened?

An old unleaded gasoline tank (tank 1) had to be neutralised.

It had been rinsed with water and then emptied, ready to be filled with liquid mortar.

While waiting for the mortar to fill tank 1, an operator wanted to open the neighbouring gasoline tank (tank 2), which was filled with water and also needed to be neutralised.

To do that, he ground the bolts of the manhole of tank 2.

Some sparks fell into the manhole of tank 1, which remained open.

Gas ignited and a flame shot out of the manhole of tank 1.

-

Why did it happen?

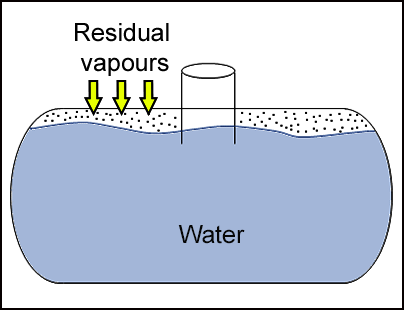

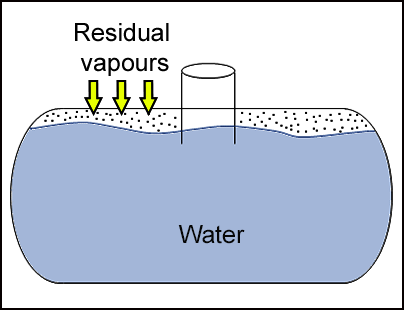

Tank 1 was equipped with a chimney going 20 cm under the manhole. In the absence of a draining system, gasoline vapours were trapped in the upper part of the tank and then sank down when the water was emptied.

The team in charge of works considered that the tank was degassed. No atmospheric test was conducted.

Grinding without protection next to a gasoline tank (manhole open).

Insufficient knowledge of risks by the contractor's staff.

Insufficient health and safety management by the general contractor.

Rare site inspections due to the geographical distance to the service station and the difficulty of mobilising human resources on site.

-

What did they learn?

Create procedures for risky work.

Identify and strengthen hot work controls to prevent similar incidents.

Ensure hot work is closely supervised. Monitor hot works daily and ensure work permit conditions are in place.

Remind staff of company rules for carrying out hot work. Ensure contractors are aware of company rules.

Hold a daily safety talk.

-

Ask yourself or your crew

How can something like this happen here?

Why do you think the worker did what he did?

At what locations should atmospheric tests be conducted?

Do we have a procedure for today’s task? How can the procedure be improved?

What hot work controls/protection do we have in place? What more can we do?

What else can we learn from this incident?

Add to homescreen

Content name

Select existing category:

Content name

New collection

Edit collection

What happened?

An old unleaded gasoline tank (tank 1) had to be neutralised.

It had been rinsed with water and then emptied, ready to be filled with liquid mortar.

While waiting for the mortar to fill tank 1, an operator wanted to open the neighbouring gasoline tank (tank 2), which was filled with water and also needed to be neutralised.

To do that, he ground the bolts of the manhole of tank 2.

Some sparks fell into the manhole of tank 1, which remained open.

Gas ignited and a flame shot out of the manhole of tank 1.

Why did it happen?

Tank 1 was equipped with a chimney going 20 cm under the manhole. In the absence of a draining system, gasoline vapours were trapped in the upper part of the tank and then sank down when the water was emptied.

The team in charge of works considered that the tank was degassed. No atmospheric test was conducted.

Grinding without protection next to a gasoline tank (manhole open).

Insufficient knowledge of risks by the contractor's staff.

Insufficient health and safety management by the general contractor.

Rare site inspections due to the geographical distance to the service station and the difficulty of mobilising human resources on site.

What did they learn?

Create procedures for risky work.

Identify and strengthen hot work controls to prevent similar incidents.

Ensure hot work is closely supervised. Monitor hot works daily and ensure work permit conditions are in place.

Remind staff of company rules for carrying out hot work. Ensure contractors are aware of company rules.

Hold a daily safety talk.

Ask yourself or your crew

How can something like this happen here?

Why do you think the worker did what he did?

At what locations should atmospheric tests be conducted?

Do we have a procedure for today’s task? How can the procedure be improved?

What hot work controls/protection do we have in place? What more can we do?

What else can we learn from this incident?

A gasoline tank in a service station had to be neutralised. After being rinsed, it was being filled with liquid mortar. A worker performed grinding work at the nearby tank without protection, which allowed a spark to enter in the first tank. A flame shot out of the manhole.