-

What happened?

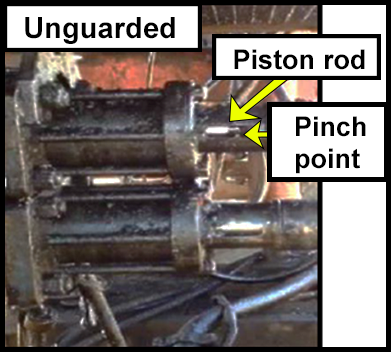

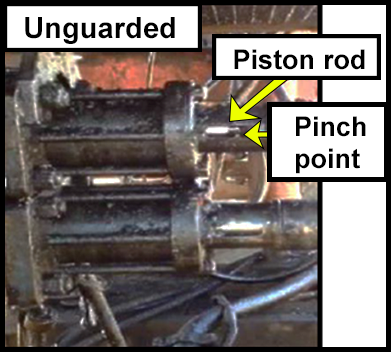

A worker’s finger was positioned inside the piston rod cylinder of a blowout preventer, through an open slot.

The machined opening on the piston rod cylinder was 7/8 inch and the rod was within an inch of the housing.

Another worker opened the blowout preventer ream.

The piston retracted. The worker’s index finger was amputated at the first joint.

-

Why did it happen?

There was no guard or protective device in place to prevent fingers getting trapped in pinch points.

Hazards associated with pinch points were not identified and addressed.

-

What did they learn?

Understand rotating equipment hazards:

- point of operation;

- power transmission;

- other moving parts.

Address potential consequences of these hazards (e.g. snagging, entanglement, entrapment, pinch points, etc.).

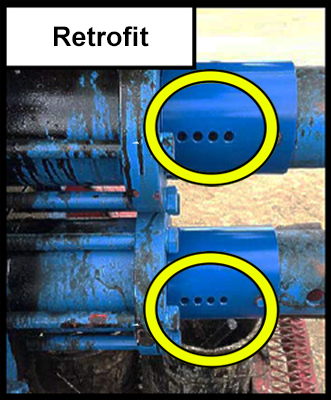

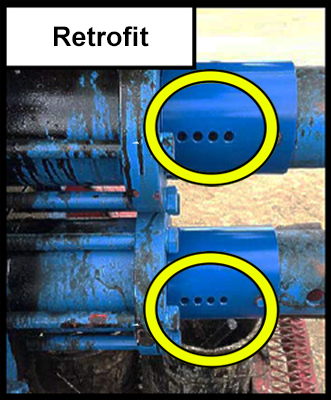

Only operate with guards and protective devices in place.

Understand PPE requirements and restrictions (where applicable).

-

Ask yourself or your crew

How can something like this happen here?

Why do you think the worker’s finger was positioned inside the piston rod cylinder when his colleague opened the piston?

What other hazards are there when working around this equipment? (What have we not thought about?)

How can we prevent something similar happening here?

Add to homescreen

Content name

Select existing category:

Content name

New collection

Edit collection

What happened?

A worker’s finger was positioned inside the piston rod cylinder of a blowout preventer, through an open slot.

The machined opening on the piston rod cylinder was 7/8 inch and the rod was within an inch of the housing.

Another worker opened the blowout preventer ream.

The piston retracted. The worker’s index finger was amputated at the first joint.

Why did it happen?

There was no guard or protective device in place to prevent fingers getting trapped in pinch points.

Hazards associated with pinch points were not identified and addressed.

What did they learn?

Understand rotating equipment hazards:

- point of operation;

- power transmission;

- other moving parts.

Address potential consequences of these hazards (e.g. snagging, entanglement, entrapment, pinch points, etc.).

Only operate with guards and protective devices in place.

Understand PPE requirements and restrictions (where applicable).

Ask yourself or your crew

How can something like this happen here?

Why do you think the worker’s finger was positioned inside the piston rod cylinder when his colleague opened the piston?

What other hazards are there when working around this equipment? (What have we not thought about?)

How can we prevent something similar happening here?

A worker’s finger was positioned inside the piston rod cylinder of a blow out preventer. His colleague’s actions caused the piston to retract, amputating his finger.