-

What happened?

A worker was coming down a 120kg (265lbs) load-rated fibreglass step ladder, set up in its unfolded position.

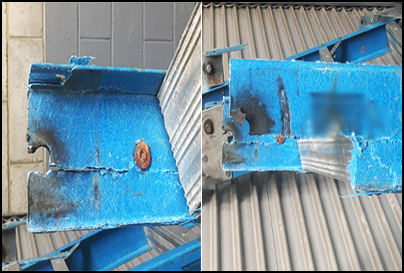

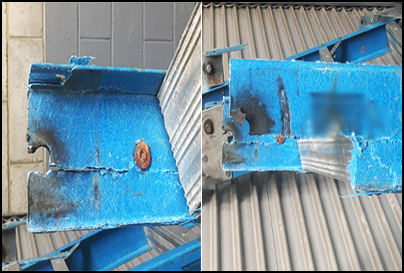

The ladder snapped in two. It broke at the main hinge point where the fibreglass stiles meet the back of the top cap.

The worker fell 2m (6.5ft), injuring his back.

-

Why did it happen?

The top cap of the ladder was damaged (perhaps by a previous impact or the ladder being dropped).

The ladder was several years old and had other signs of wear and tear.

Fibreglass and plastic ladders have more problems with degrading than metal ladders.

-

What did they learn?

All ladders should be regularly checked and maintained in good condition.

Fibreglass and plastic ladders require close inspection, which should include checks on:

- Fibreglass for wear, cracks around the rivets and bolt holes, and ‘blooming’ (glass fibres breaking through the surface, which can reduce electrical insulation).

- Bolts and rivets should be present and secure.

- Hinges should not have any loose or cracked rungs.

- Internal and external corrosion.

- All pivoting or rotating surfaces should move freely – lubricate as per manufacturer’s instructions when required.

- Ensure ladder feet are not excessively worn or missing.

Ladder inspections should take place:

- when originally purchased, received or put into service

- before each use

- after mishaps, drops and impacts

- periodically to check for signs of degradation

If a ladder is defective, it should be sent for repair or to be destroyed.

-

Ask yourself or your crew

How do you know which ladder type you can use safely for your task?

What will you check before using the ladder today? If something does not look right, what should you do?

How should a ladder be positioned safely (think of the feet, what can the ladder be rested against, how can you move it in a safe manner)?

What is the technique to safely ascend and descend ladders?

Add to homescreen

Content name

Select existing category:

Content name

New collection

Edit collection

What happened?

A worker was coming down a 120kg (265lbs) load-rated fibreglass step ladder, set up in its unfolded position.

The ladder snapped in two. It broke at the main hinge point where the fibreglass stiles meet the back of the top cap.

The worker fell 2m (6.5ft), injuring his back.

Why did it happen?

The top cap of the ladder was damaged (perhaps by a previous impact or the ladder being dropped).

The ladder was several years old and had other signs of wear and tear.

Fibreglass and plastic ladders have more problems with degrading than metal ladders.

What did they learn?

All ladders should be regularly checked and maintained in good condition.

Fibreglass and plastic ladders require close inspection, which should include checks on:

- Fibreglass for wear, cracks around the rivets and bolt holes, and ‘blooming’ (glass fibres breaking through the surface, which can reduce electrical insulation).

- Bolts and rivets should be present and secure.

- Hinges should not have any loose or cracked rungs.

- Internal and external corrosion.

- All pivoting or rotating surfaces should move freely – lubricate as per manufacturer’s instructions when required.

- Ensure ladder feet are not excessively worn or missing.

Ladder inspections should take place:

- when originally purchased, received or put into service

- before each use

- after mishaps, drops and impacts

- periodically to check for signs of degradation

If a ladder is defective, it should be sent for repair or to be destroyed.

Ask yourself or your crew

How do you know which ladder type you can use safely for your task?

What will you check before using the ladder today? If something does not look right, what should you do?

How should a ladder be positioned safely (think of the feet, what can the ladder be rested against, how can you move it in a safe manner)?

What is the technique to safely ascend and descend ladders?

A worker was injured after falling from a fibreglass ladder after the ladder snapped in two. It broke at the main hinge point where the fibreglass stiles meet the back of the top cap.