-

What happened?

A crane crew was preparing to blind lift two mushroom anchors from the safe welding area to the completions deck.

During the lift, one of the mushroom anchors hung up on the lip of the riser deck.

The anchor detached from the sling's safety clamp and fell 16ft/5m to the main deck.

Nobody was injured. The nearest person was 8ft/2.5m away, and the next closest person was 15ft/4.5m away from the dropped object.

-

Why did it happen?

Inadequate risk assessment and mitigation for lifting and rigging operation. Conditions weren’t anticipated, and hazards weren’t recognised:

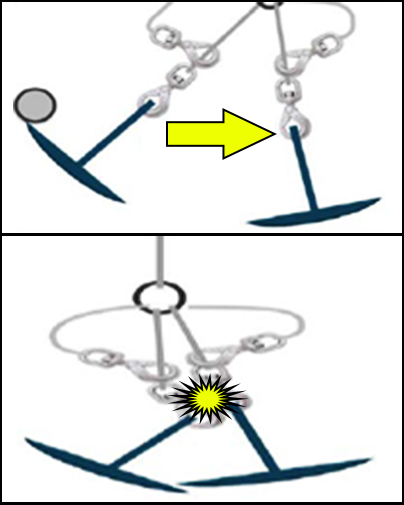

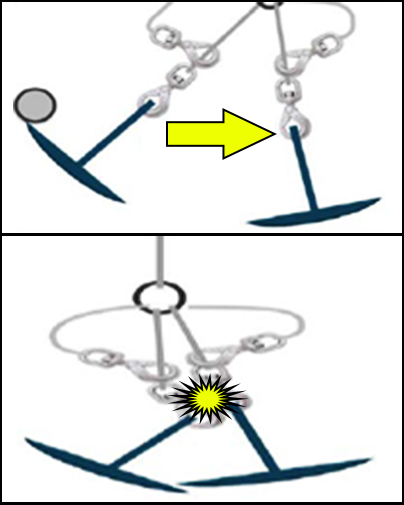

- Lifting and rigging arrangements were unsuitable for the operation.

- Using 2 hooks that may contact each other introduced significant risks.

- Hook locking mechanisms may open as a result of unintentional contact if the hook is ‘offloaded’ at that moment.

The lifting arrangements only used equipment readily at hand and convenient for the crew.

Although an accepted and established rigging method was used, the controls were inadequate for lifting a load through a narrow (2m/6ft wide) gap between the welding area and deck.

-

What did they learn?

Conducting crane lifts through the narrow gap between the welding area and completions deck was prohibited.

Where contact between hooks is possible, consider alternative rigging arrangement.

Eye hooks should not be used for deck lifts if the arrangement allows contact between hooks while the load is suspended. Alternatively, lift items individually or use shackles instead of hooks.

Update rig procedure to include the learnings. Communicate new rig procedure to all who need to know.

-

Ask yourself or your crew

How could something like this happen here?

Think about today’s lifting operation:

- Can the hooks connect with each other?

- What could the load get caught on?

- How could the load become detached?

- What would happen if the load fell?

What controls do we have in place to keep our lifting operations safe? What more can be done?

What else can we learn from this incident?

Add to homescreen

Content name

Select existing category:

Content name

New collection

Edit collection

What happened?

A crane crew was preparing to blind lift two mushroom anchors from the safe welding area to the completions deck.

During the lift, one of the mushroom anchors hung up on the lip of the riser deck.

The anchor detached from the sling's safety clamp and fell 16ft/5m to the main deck.

Nobody was injured. The nearest person was 8ft/2.5m away, and the next closest person was 15ft/4.5m away from the dropped object.

Why did it happen?

Inadequate risk assessment and mitigation for lifting and rigging operation. Conditions weren’t anticipated, and hazards weren’t recognised:

- Lifting and rigging arrangements were unsuitable for the operation.

- Using 2 hooks that may contact each other introduced significant risks.

- Hook locking mechanisms may open as a result of unintentional contact if the hook is ‘offloaded’ at that moment.

The lifting arrangements only used equipment readily at hand and convenient for the crew.

Although an accepted and established rigging method was used, the controls were inadequate for lifting a load through a narrow (2m/6ft wide) gap between the welding area and deck.

What did they learn?

Conducting crane lifts through the narrow gap between the welding area and completions deck was prohibited.

Where contact between hooks is possible, consider alternative rigging arrangement.

Eye hooks should not be used for deck lifts if the arrangement allows contact between hooks while the load is suspended. Alternatively, lift items individually or use shackles instead of hooks.

Update rig procedure to include the learnings. Communicate new rig procedure to all who need to know.

Ask yourself or your crew

How could something like this happen here?

Think about today’s lifting operation:

- Can the hooks connect with each other?

- What could the load get caught on?

- How could the load become detached?

- What would happen if the load fell?

What controls do we have in place to keep our lifting operations safe? What more can be done?

What else can we learn from this incident?

A crane crew was preparing to blind lift two mushroom anchors from the safe welding area to the completions deck. A combination of inadequate risk assessment and inadequate controls caused one of the anchors to detach from the sling's safety clamp. It fell 16ft/5m to the main deck. Luckily, nobody was injured.