-

What happened?

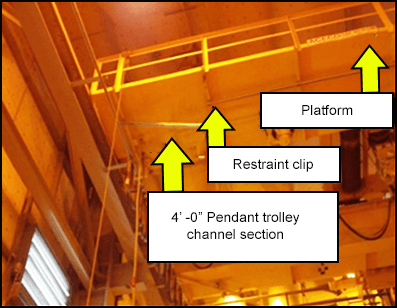

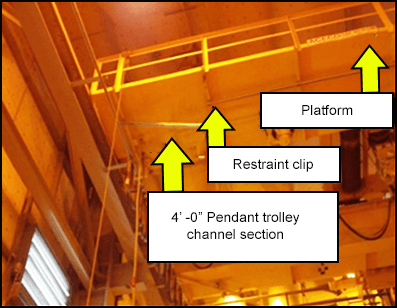

A technician was inspecting operations from a crane platform.

To operate it, he pulled the control pendant and cables up to the platform.

Afterwards, while lowering the control pendant and cable, a section of the channel rail system detached from its restraint clip at one end.

The pendant trolley and cable support festoon system rolled out of the channel and fell 30 feet/9 metres.

-

Why did it happen?

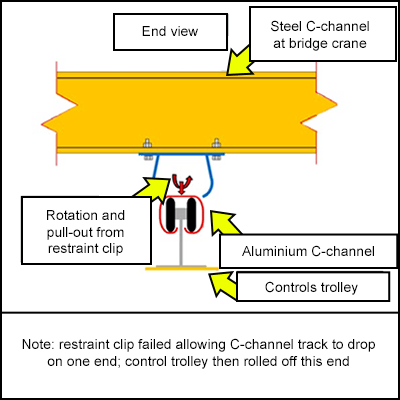

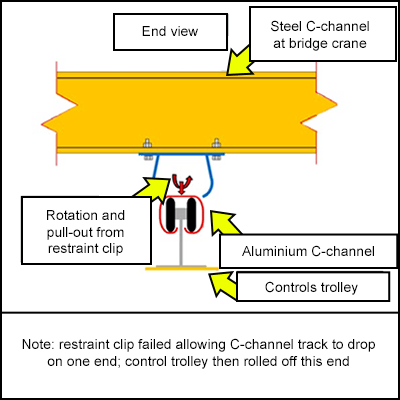

Shock loading occurred when lowering the pendant.

Long-term side loading from pendant use caused the restraint clip to widen. The channel rail eventually became detached.

Pendant rail system was not engineered correctly or properly installed.

Strain relief system was modified (from balance assembly to a four-chain configuration) without using a management of change process.

Maintenance technician was not familiar with bridge crane access procedures.

-

What did they learn?

Establish an exclusion zone, even if not using tools on the platform.

Perform thorough task risk assessment, identifying all potential hazards.

Use a management of change process for any changes to the original design or installation.

Follow manufacturer recommendations and local written procedures for using platforms. Review and approve procedures before starting work .

Include all parts and assemblies of platforms into equipment inspection programs. Consider the age of equipment and potential for dropped objects hazards.

-

Ask yourself or your crew

What other actions could have been taken?

How can something like this happen here?

What other hazards have we not considered when working with crane platforms?

Are we familiar with how to properly use bridge cranes?

Add to homescreen

Content name

Select existing category:

Content name

New collection

Edit collection

What happened?

A technician was inspecting operations from a crane platform.

To operate it, he pulled the control pendant and cables up to the platform.

Afterwards, while lowering the control pendant and cable, a section of the channel rail system detached from its restraint clip at one end.

The pendant trolley and cable support festoon system rolled out of the channel and fell 30 feet/9 metres.

Why did it happen?

Shock loading occurred when lowering the pendant.

Long-term side loading from pendant use caused the restraint clip to widen. The channel rail eventually became detached.

Pendant rail system was not engineered correctly or properly installed.

Strain relief system was modified (from balance assembly to a four-chain configuration) without using a management of change process.

Maintenance technician was not familiar with bridge crane access procedures.

What did they learn?

Establish an exclusion zone, even if not using tools on the platform.

Perform thorough task risk assessment, identifying all potential hazards.

Use a management of change process for any changes to the original design or installation.

Follow manufacturer recommendations and local written procedures for using platforms. Review and approve procedures before starting work .

Include all parts and assemblies of platforms into equipment inspection programs. Consider the age of equipment and potential for dropped objects hazards.

Ask yourself or your crew

What other actions could have been taken?

How can something like this happen here?

What other hazards have we not considered when working with crane platforms?

Are we familiar with how to properly use bridge cranes?

A technician was inspecting operations from a crane platform. While lowering the control pendant and cable, a section of the channel rail system detached from its restraint clip at one end.