-

What happened?

These two incidents involve times where the counterweight has fallen from rigs whilst the rigs were being installed or removed.

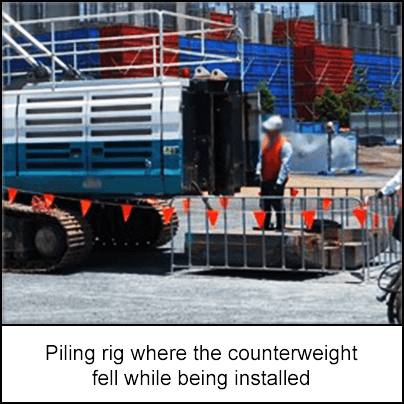

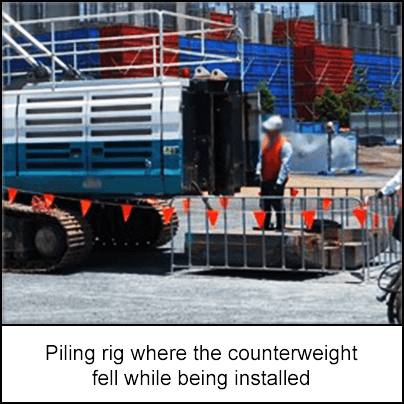

In the first incident, a mobile piling rig was being assembled. A 13.4 tonnes counterweight fell off the back of the rig, injuring one worker and narrowly missing another.

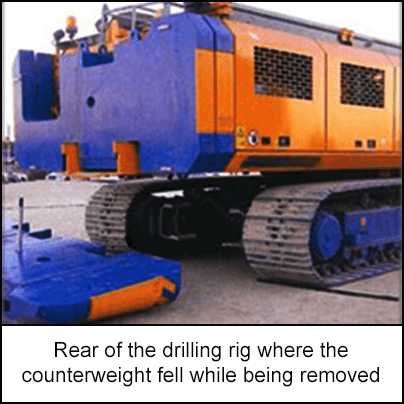

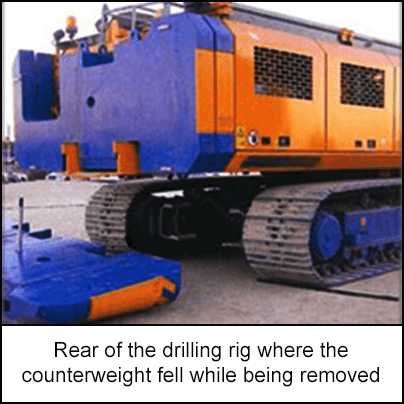

In the second incident, a mobile drilling rig was being prepared for transport. A 10.5 tonnes counterweight fell from the back of the rig, killing a worker.

-

Why did it happen?

The design of the system differed in both incidents, but ultimately the counterweight was able to fall because it was not supported while bolts were being installed.

There was no system in place to support the counterweight while being assembled/disassembled.

Workers were in the fall zone when installing the counterweight due to the design of the rigs.

-

What did they learn?

The use of a crane and lifting gear to stabilise the counterweight while workers are located in the potential fall zone of the counterweight is not acceptable.

Counterweight assembly should be designed so that a person never needs to be in the fall zone. There are three main choices. The counterweight either:

- sits in a cradle while being installed, and is lifted in and out of this;

- has pins on top of it so that the workers do not need to be in the fall zone. The counterweight would need to be suspended from a crane so that the pins can be removed, or

- is fitted by a lifting device on the plant. When it is in position a locking device secures it without workers needing to be in the fall zone.

The system requires a better safe work procedure – with full description of the process to be followed.

Ensure that anyone working on counterweights has a high-risk work licence as an intermediate rigger.

-

Ask yourself or your crew

Have you ever seen a counterweight fail while being installed/removed? What happened?

What is our process for rigging up a counterweight? Does it require someone to be in the fall zone?

How can be change our work process to ensure no one needs to be in the fall zone?

Would any of the three options above for a safe fitting of a counterweight work on your site? Why/why not?

Add to homescreen

Content name

Select existing category:

Content name

New collection

Edit collection

What happened?

These two incidents involve times where the counterweight has fallen from rigs whilst the rigs were being installed or removed.

In the first incident, a mobile piling rig was being assembled. A 13.4 tonnes counterweight fell off the back of the rig, injuring one worker and narrowly missing another.

In the second incident, a mobile drilling rig was being prepared for transport. A 10.5 tonnes counterweight fell from the back of the rig, killing a worker.

Why did it happen?

The design of the system differed in both incidents, but ultimately the counterweight was able to fall because it was not supported while bolts were being installed.

There was no system in place to support the counterweight while being assembled/disassembled.

Workers were in the fall zone when installing the counterweight due to the design of the rigs.

What did they learn?

The use of a crane and lifting gear to stabilise the counterweight while workers are located in the potential fall zone of the counterweight is not acceptable.

Counterweight assembly should be designed so that a person never needs to be in the fall zone. There are three main choices. The counterweight either:

- sits in a cradle while being installed, and is lifted in and out of this;

- has pins on top of it so that the workers do not need to be in the fall zone. The counterweight would need to be suspended from a crane so that the pins can be removed, or

- is fitted by a lifting device on the plant. When it is in position a locking device secures it without workers needing to be in the fall zone.

The system requires a better safe work procedure – with full description of the process to be followed.

Ensure that anyone working on counterweights has a high-risk work licence as an intermediate rigger.

Ask yourself or your crew

Have you ever seen a counterweight fail while being installed/removed? What happened?

What is our process for rigging up a counterweight? Does it require someone to be in the fall zone?

How can be change our work process to ensure no one needs to be in the fall zone?

Would any of the three options above for a safe fitting of a counterweight work on your site? Why/why not?

In these two incidents, counterweights were being fitted to the rigs when the partially installed bolts failed. This caused injuries and deaths to the workers involved.