-

What happened?

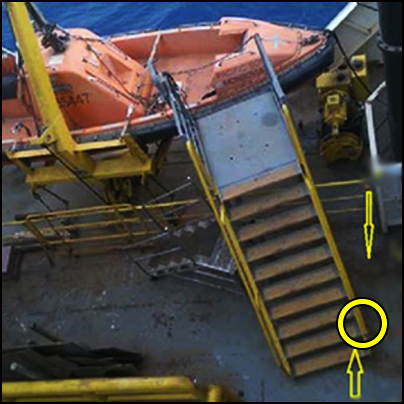

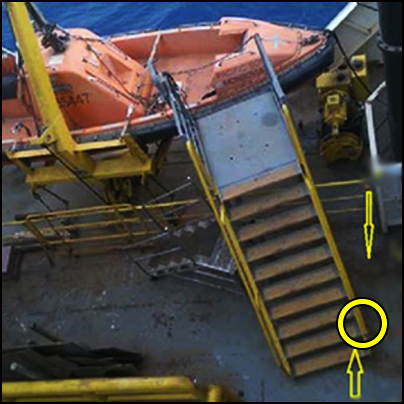

A mechanic was installing a safety barrier clip on a rescue craft.

He drilled a 3.5mm hole into the access stair handrail.

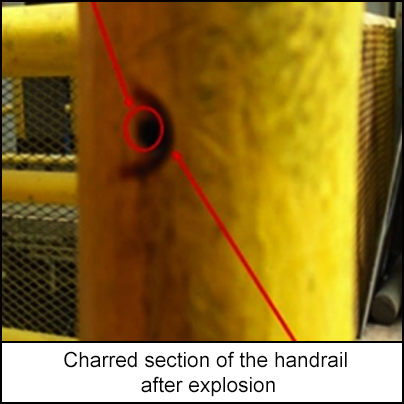

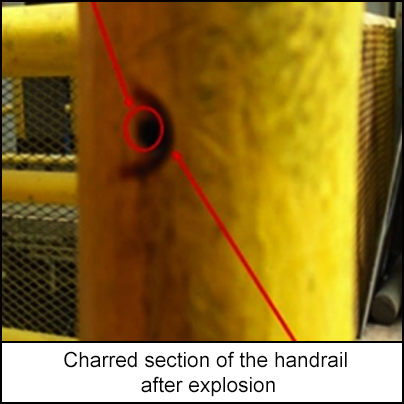

When the drill bit penetrated the wall of the handrail pipe, there was a release of an unknown flammable gas.

The gas ignited, causing a fire. The mechanic suffered burns which required hospitalisation.

-

Why did it happen?

The mechanic was in the line of fire. He was not wearing his personal protective equipment (PPE) fastened correctly.

The drilling introduced a heat source which ignited the hazardous gases when released.

The presence of hazardous gas was unexpected, and therefore not accounted for in any risk assessments.

The design of the handrail allowed the accumulation of hazardous gas (hollow and enclosed structures, no venting).

The construction of the low-grade steel handrail contributed to the accumulation of a combination of hazardous gases.

The mechanic had a paper copy of the risk assessment sticking out of his pocket, which ignited and caused a heat spot, intensifying his burns.

-

What did they learn?

Handrail design should aim to avoid the accumulation of gases inside hollow and enclosed structures (e.g. angle irons, non-metallic tubers, add vent holes).

Establish procedures to safely tap into hollow, enclosed structures which may have hazardous gas inside.

PPE should be worn correctly.

Be aware of the risks of hazardous gas accumulation in hollow and enclosed structures.

- Specific standards/procedures should be in place for work on such structures.

- Risk assessments should include these risks.

-

Ask yourself or your crew

Are there any structures on your site that could allow the accumulation of hazardous gases? Could these be designed/constructed differently to avoid the hazards?

What is our procedure for checking for hazardous gas in hollow, enclosed structures? If there isn’t one, how can we implement this on our site?

What should you do if you observe your colleagues wearing their PPE incorrectly?

How can you verify that all risks have been considered and mitigated before starting your task?

Add to homescreen

Content name

Select existing category:

Content name

New collection

Edit collection

What happened?

A mechanic was installing a safety barrier clip on a rescue craft.

He drilled a 3.5mm hole into the access stair handrail.

When the drill bit penetrated the wall of the handrail pipe, there was a release of an unknown flammable gas.

The gas ignited, causing a fire. The mechanic suffered burns which required hospitalisation.

Why did it happen?

The mechanic was in the line of fire. He was not wearing his personal protective equipment (PPE) fastened correctly.

The drilling introduced a heat source which ignited the hazardous gases when released.

The presence of hazardous gas was unexpected, and therefore not accounted for in any risk assessments.

The design of the handrail allowed the accumulation of hazardous gas (hollow and enclosed structures, no venting).

The construction of the low-grade steel handrail contributed to the accumulation of a combination of hazardous gases.

The mechanic had a paper copy of the risk assessment sticking out of his pocket, which ignited and caused a heat spot, intensifying his burns.

What did they learn?

Handrail design should aim to avoid the accumulation of gases inside hollow and enclosed structures (e.g. angle irons, non-metallic tubers, add vent holes).

Establish procedures to safely tap into hollow, enclosed structures which may have hazardous gas inside.

PPE should be worn correctly.

Be aware of the risks of hazardous gas accumulation in hollow and enclosed structures.

- Specific standards/procedures should be in place for work on such structures.

- Risk assessments should include these risks.

Ask yourself or your crew

Are there any structures on your site that could allow the accumulation of hazardous gases? Could these be designed/constructed differently to avoid the hazards?

What is our procedure for checking for hazardous gas in hollow, enclosed structures? If there isn’t one, how can we implement this on our site?

What should you do if you observe your colleagues wearing their PPE incorrectly?

How can you verify that all risks have been considered and mitigated before starting your task?

A mechanic was working on a rescue craft. They drilled a 3.5mm hole into the access stair handrail and flammable gas was released, causing a fire. The mechanic suffered burns which required hospitalisation.