-

What happened?

After a work crew had completed backloading operations to a standby vessel, the crane operator was setting the crane in the rest.

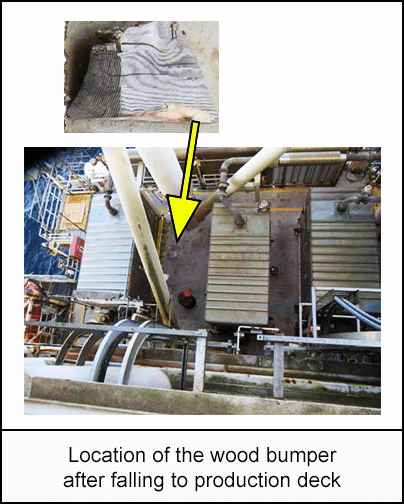

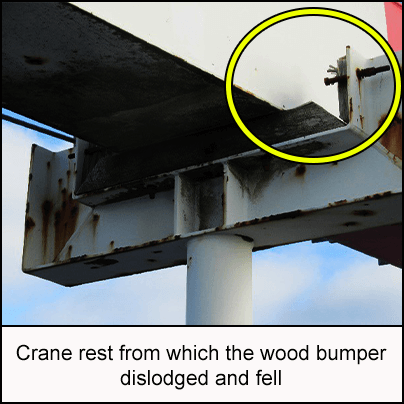

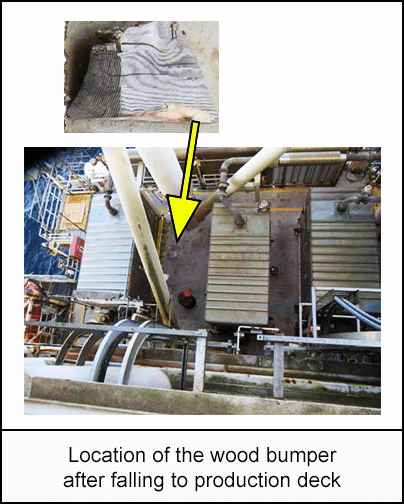

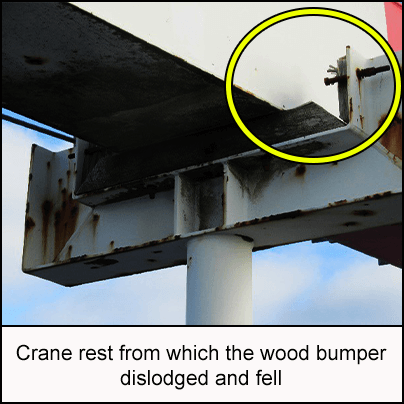

When the crane entered the rest, a piece of wood bumper weighing 0.8kg (1.8lbs) dislodged from the rest.

It fell 17m (56.5ft) to the production deck.

Fortunately, no workers were in the immediate area, so no one was injured.

This incident could have been fatal.

-

Why did it happen?

The wood became weathered and damaged over time.

Previously identified cracks had not been raised as a drop concern.

The inspection regime was not frequent enough.

There was no requirement for drop zone barriers to be installed as the lifting operations had been completed.

-

What did they learn?

Add crane rest bumper inspection to the crane pre-use checklists.

Verify that periodic inspections are being carried out on the equipment you work with.

Investigate if bumpers made of other materials would be more suitable.

-

Ask yourself or your crew

What weathering risks do you need to be aware of for the equipment you work with?

How do you report a hazard when you see one (outside the periodic inspections)?

What is our inspection regime for cranes? What about dropped objects prevention?

What measures do we have in place to prevent this from happening here? How can we improve?

Add to homescreen

Content name

Select existing category:

Content name

New collection

Edit collection

What happened?

After a work crew had completed backloading operations to a standby vessel, the crane operator was setting the crane in the rest.

When the crane entered the rest, a piece of wood bumper weighing 0.8kg (1.8lbs) dislodged from the rest.

It fell 17m (56.5ft) to the production deck.

Fortunately, no workers were in the immediate area, so no one was injured.

This incident could have been fatal.

Why did it happen?

The wood became weathered and damaged over time.

Previously identified cracks had not been raised as a drop concern.

The inspection regime was not frequent enough.

There was no requirement for drop zone barriers to be installed as the lifting operations had been completed.

What did they learn?

Add crane rest bumper inspection to the crane pre-use checklists.

Verify that periodic inspections are being carried out on the equipment you work with.

Investigate if bumpers made of other materials would be more suitable.

Ask yourself or your crew

What weathering risks do you need to be aware of for the equipment you work with?

How do you report a hazard when you see one (outside the periodic inspections)?

What is our inspection regime for cranes? What about dropped objects prevention?

What measures do we have in place to prevent this from happening here? How can we improve?

A crane operator was setting the crane in its rest, when a piece of wood bumper was dislodged and fell 17m (56.5ft) to the production deck. Fortunately, no workers were in the immediate area, so no one was injured. This incident could have been fatal.