-

What happened?

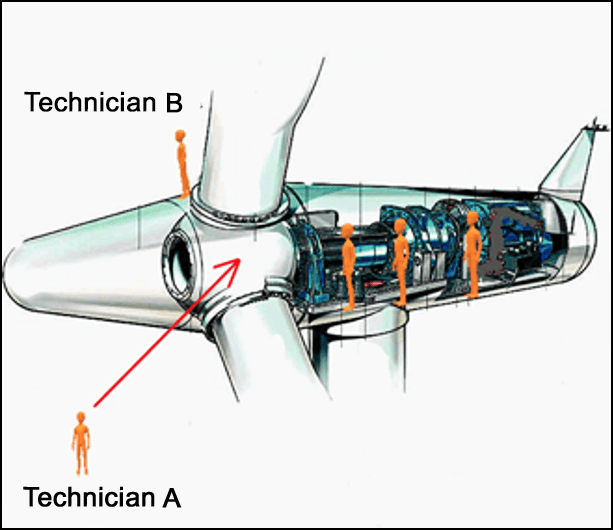

A group of technicians were in the process of reinstalling a rotor to a nacelle. This required one technician (A) to be inside the hub to first mount and tighten the bolts between the hub and nacelle, and then remove the lifting brackets.

The rotor was successfully mounted and was about to be released from the lifting yoke. This required one technician (B) to crawl up on the exterior of the hub and release the lifting brackets.

Technician A released the crane and lifting brackets and began bolting the spinner plate back on, when suddenly the rotor started moving.

Technician B realised this unexpected rotation and quickly moved towards safety inside the nacelle. Technician A immediately became aware of the unexpected movement and prepared themselves by holding on to whatever they could find.

The rotor turned somewhere between 60-90 degrees before it impacted with the boom of the crane which stopped it from spinning.

No person was injured during the incident.

-

Why did it happen?

The high-speed rotor locks were not installed as per work instruction.

The high-speed rotor locks were not installed due to lack of control over critical point of isolation steps and insufficient safeguards to counteract memory slips and complacency.

-

What did they learn?

Enforce strict control over critical points of isolation steps to ensure no hazardous energy can be released during work.

Implement checklists for critical points of isolation steps and safeguarding against memory slips and complacency.

-

Ask yourself or your crew

How can something like this happen here?

What checks can you do to ensure that no hazardous energy can be released while you and your team conduct the task?

What safety measures (i.e. procedures, controls/barriers) do we have in place to mitigate the risk?

What improvements or changes should we make to the procedures, controls/barriers, or the way we work?

Add to homescreen

If you want to add this app to home screen tap and then ‘Add to Home Screen’.

Content name

Select existing category:

Content name

New collection

Edit collection

Published on 20/03/23

1325 Views

A group of technicians were in the process of reinstalling a rotor to a nacelle. During the task, the rotor started moving unexpectedly. Fortunately, no one was injured. The investigation revealed that the high-speed rotor locks were not installed as per work instruction.