-

What happened?

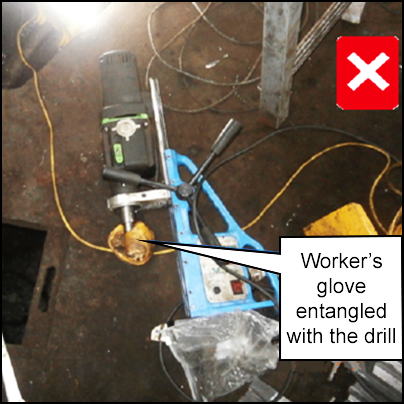

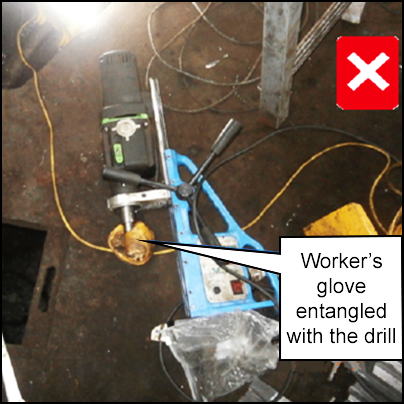

A worker was undertaking drilling operations on the inside of an offshore wind turbine using a magnetic drill.

One of his gloves became entangled with a strand of swarf and drawn into the rotating drill.

The worker sustained an amputation above the top joint of his little finger and deep cuts to the thumb and back of the hand.

A colleague unplugged the drill and administered emergency first aid.

All drilling operations were suspended and a site safety stand-down was conducted.

-

Why did it happen?

The drilling machine was supplied and used without an appropriate tool guard.

The worker was wearing loose fitting leather gloves which increased the chances of entanglement.

The worker did not follow the control measures defined and through the risk assessment process.

-

What did they learn?

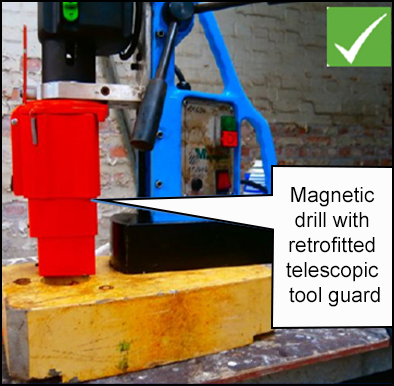

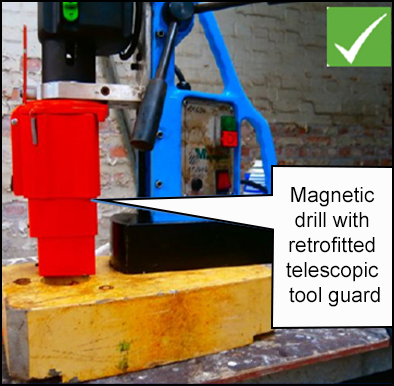

Ensure all newly sourced machine tools are retrofitted with appropriate safeguards conform to all relevant standards.

Evaluate the use of hand protection whilst operating rotating plant and equipment to ensure that the risk of entanglement has not increased.

Consider the use of swarf chipping tooling or a ‘pecking’ drilling process to prevent long strands of swarf developing during drilling.

All workers should be trained to understand how to operate their machines, the risks associated with using the machines and precautions required to prevent injury.

-

Ask yourself or your crew

What are the risks/dangers associated with your equipment for today’s drilling task?

Do your drilling machines have the correct tool guards fitted? What should you do if not?

Is your PPE appropriate for the task? If not, how can you obtain PPE that is better suited?

What risk assessments do you carry out before starting work? What procedures should you follow?

Add to homescreen

Content name

Select existing category:

Content name

New collection

Edit collection

What happened?

A worker was undertaking drilling operations on the inside of an offshore wind turbine using a magnetic drill.

One of his gloves became entangled with a strand of swarf and drawn into the rotating drill.

The worker sustained an amputation above the top joint of his little finger and deep cuts to the thumb and back of the hand.

A colleague unplugged the drill and administered emergency first aid.

All drilling operations were suspended and a site safety stand-down was conducted.

Why did it happen?

The drilling machine was supplied and used without an appropriate tool guard.

The worker was wearing loose fitting leather gloves which increased the chances of entanglement.

The worker did not follow the control measures defined and through the risk assessment process.

What did they learn?

Ensure all newly sourced machine tools are retrofitted with appropriate safeguards conform to all relevant standards.

Evaluate the use of hand protection whilst operating rotating plant and equipment to ensure that the risk of entanglement has not increased.

Consider the use of swarf chipping tooling or a ‘pecking’ drilling process to prevent long strands of swarf developing during drilling.

All workers should be trained to understand how to operate their machines, the risks associated with using the machines and precautions required to prevent injury.

Ask yourself or your crew

What are the risks/dangers associated with your equipment for today’s drilling task?

Do your drilling machines have the correct tool guards fitted? What should you do if not?

Is your PPE appropriate for the task? If not, how can you obtain PPE that is better suited?

What risk assessments do you carry out before starting work? What procedures should you follow?

A worker was undertaking drilling operations on the inside of an offshore wind turbine. They were using a magnetic based drill when their right hand was drawn into the rotating drill.